0102030405

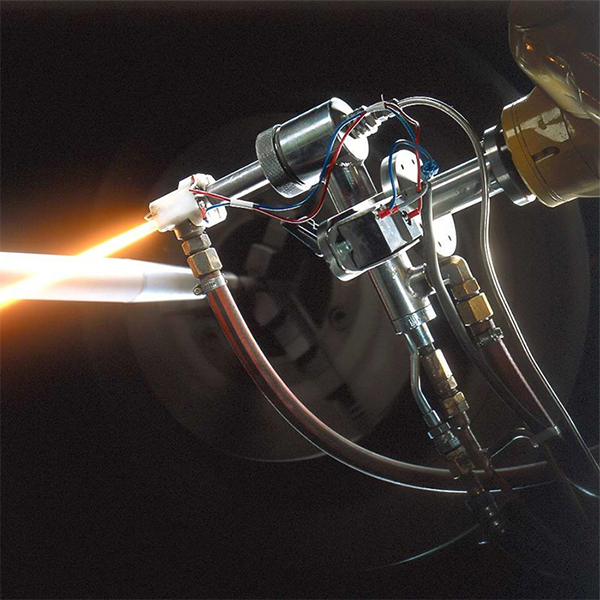

WC-10Ni HVOF/HVAF thermal spray powder, Suitable for wet working environments

Product Performance

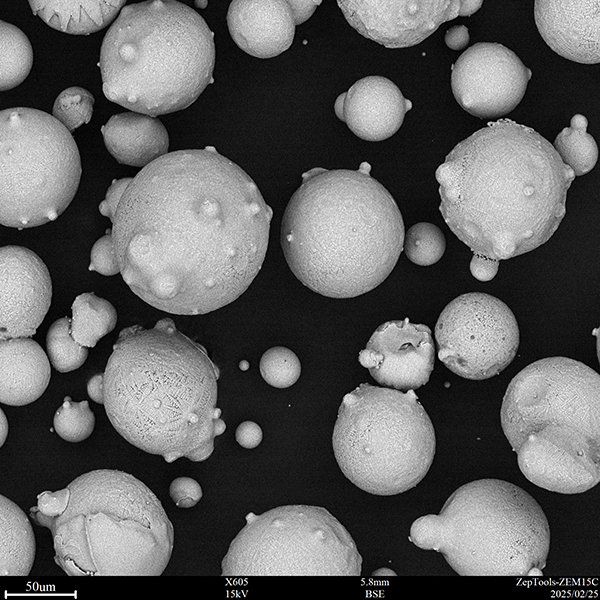

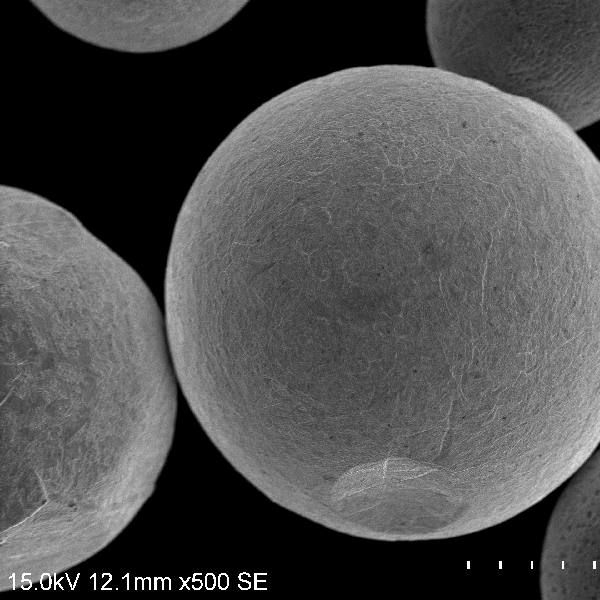

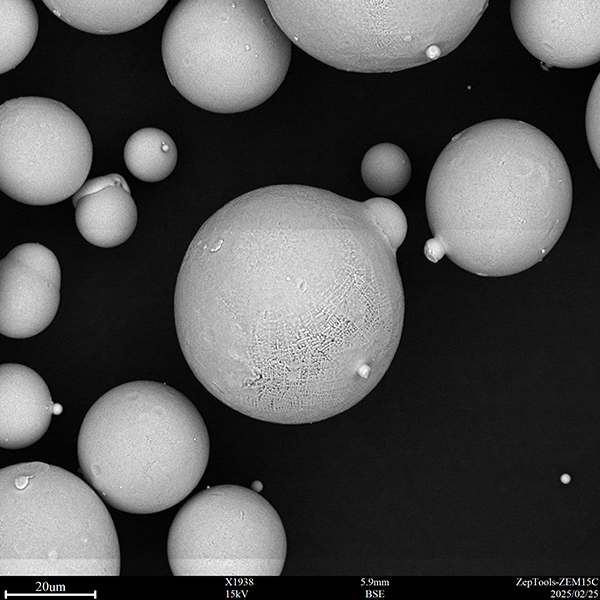

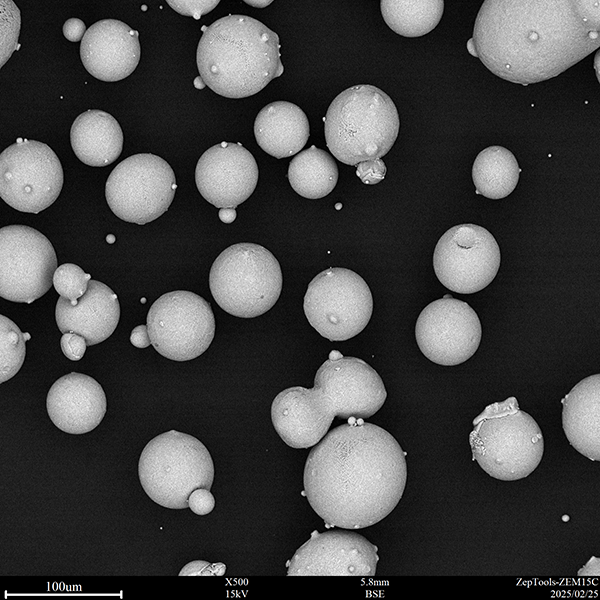

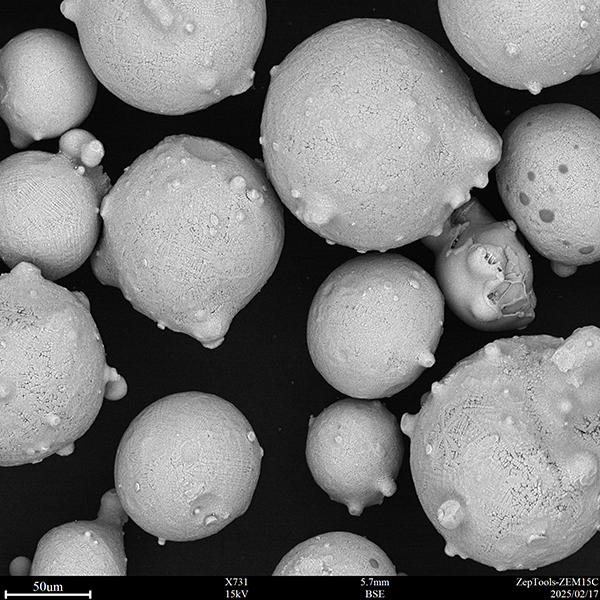

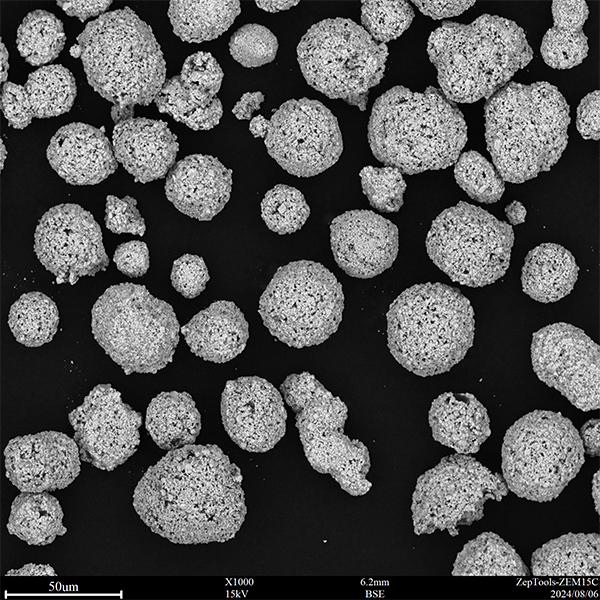

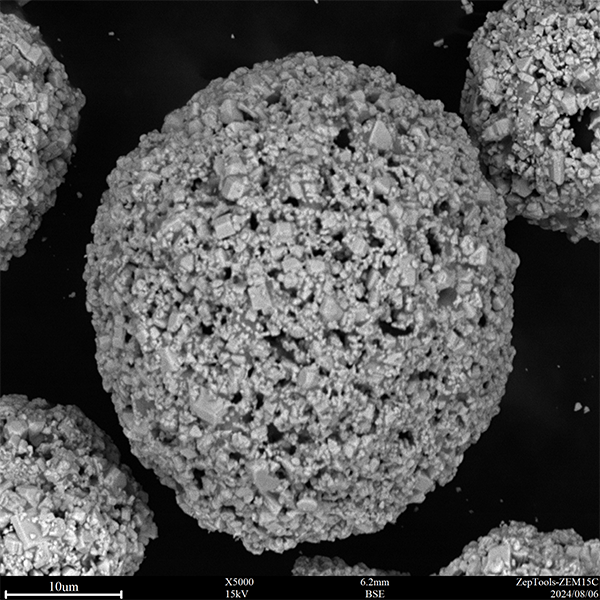

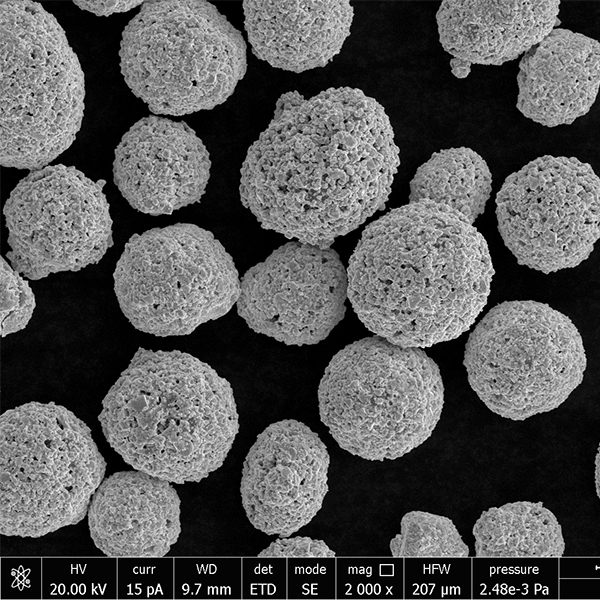

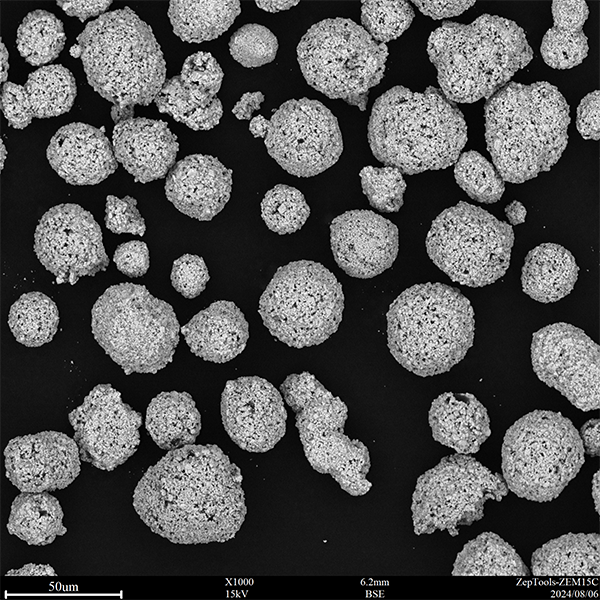

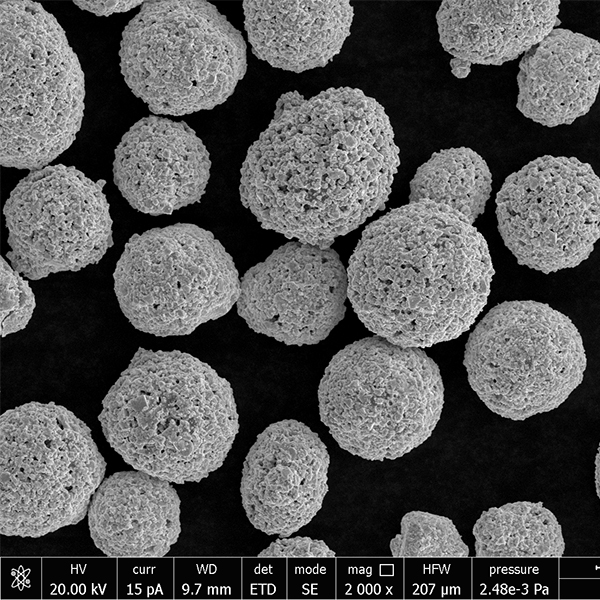

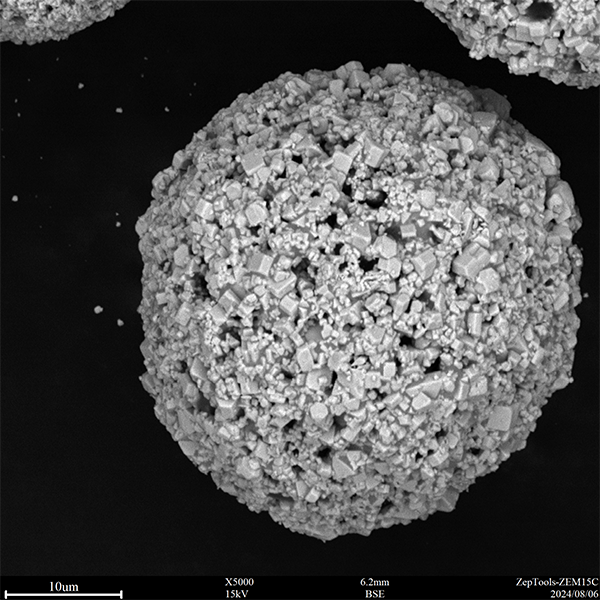

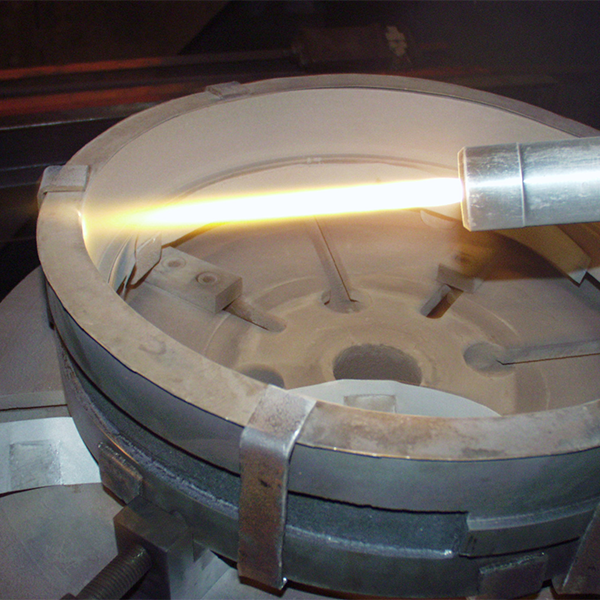

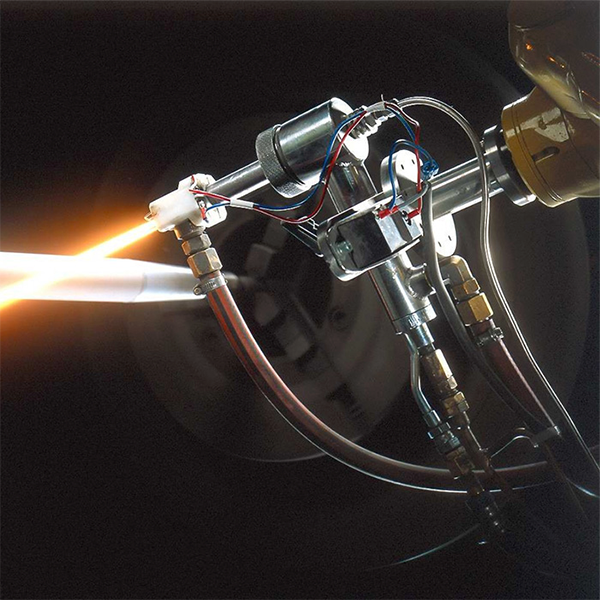

The main features of DG.WC-Ni10 powder are its excellent wear resistance and corrosion resistance. The powder is in the form of agglomerated and sintered spherical particles with good fluidity and is easy to spray. The coating has high hardness and high density, and can effectively resist particle wear, sliding wear and corrosive wear. Compared with traditional WC-Co spray powder, DG.WC-Ni10 performs better in corrosion resistance and is suitable for use in a variety of harsh environments.

The maximum working environment temperature of the coating can reach 500℃, so it can maintain good performance under high temperature conditions. In addition, the DG.WC-Ni10 coating has non-magnetic properties and is suitable for use in applications with strict requirements on magnetism.

Typical Applications

DG.WC-Ni10 is widely used in many industries, especially in chemical industry, marine engineering and heavy industry. The following are some typical applications:

Chemical Industry: In chemical equipment, DG.WC-Ni10 coating can effectively resist chemical corrosion, extend the service life of equipment and reduce maintenance costs. It is often used to protect key components such as reactors, pipelines and valves.

Offshore oil exploration equipment: In the marine environment, equipment is often exposed to salt water corrosion and wear. DG.WC-Ni10 coating can provide excellent corrosion resistance and wear resistance, ensuring the stable operation of the equipment.

Offshore heavy industry: In the field of offshore heavy industry, DG.WC-Ni10 coating is suitable for various heavy machinery and equipment. It can effectively resist wear and corrosion and ensure the efficient operation of equipment.

Valves and ball valves: DG.WC-Ni10 coating is commonly used for surface treatment of various valves and ball valves, providing excellent wear resistance and corrosion resistance, ensuring the reliability of valves under high pressure and high temperature environments.

In conclusion

DG.WC-Ni10 is an ideal thermal spray powder. With its excellent performance and wide application fields, it has become the preferred material in the industry. Whether in high temperature, high wear environment or in applications requiring high corrosion resistance, DG.WC-Ni10 can provide reliable solutions to help companies improve production efficiency and reduce operating costs. Choosing DG.WC-Ni10, you will get excellent surface protection and lasting performance guarantee.

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.