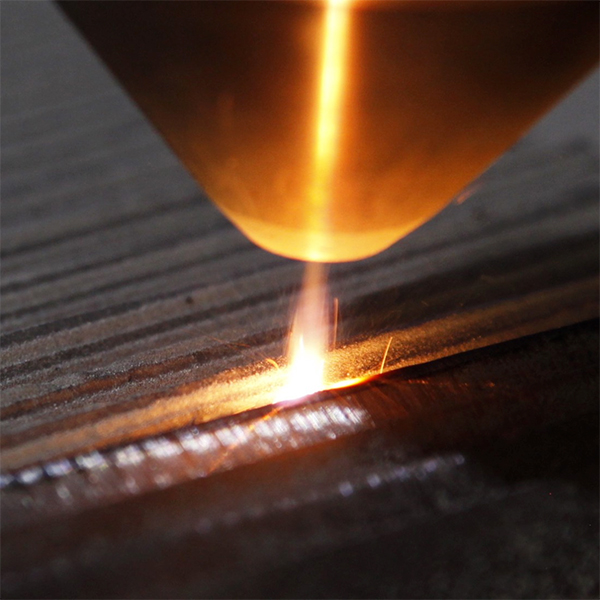

Stainless Steel 316L Powder (for Laser Cladding)

Key Features

Applications

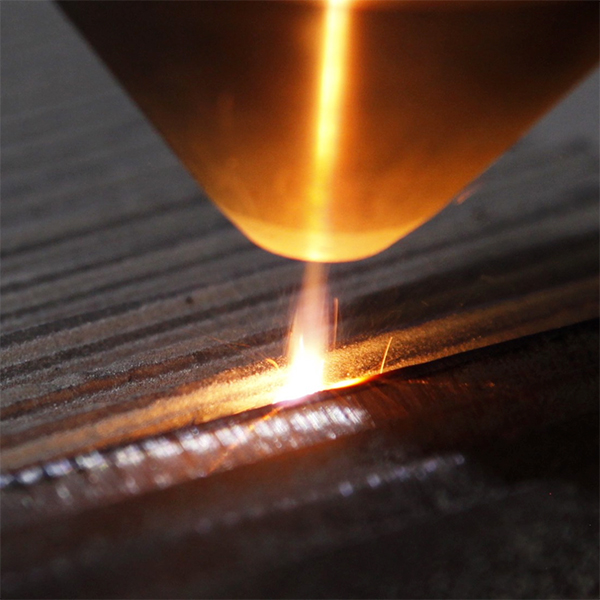

Laser cladding uses high-energy lasers to metallurgically bond 316L powder to substrates, forming dense, corrosion-resistant coatings or repair layers. Key applications include:

Marine Engineering & Shipbuilding

Components: Ship valves, propeller shafts, seawater pump parts.

Advantages: Resists seawater corrosion and biofouling, extending equipment lifespan.

Petrochemical Industry

Components: Pipeline interiors, reactor vessels, valve sealing surfaces.

Advantages: Withstands corrosive media (e.g., H₂S, CO₂), preventing leaks.

Medical Devices

Components: Surgical tools, implant surface coatings.

Advantages: Biocompatible, corrosion-resistant to bodily fluids, and easy to sterilize.

Aerospace

Components: Engine parts, landing gear repairs.

Advantages: Resists oxidation and fatigue under alternating high/low temperatures.

Mold & Machinery Remanufacturing

Components: Injection molds, roller surface repairs.

Advantages: Restores dimensions while improving surface hardness (e.g., combined with tungsten carbide reinforcement).

Nuclear Energy

Components: Cooling system parts in nuclear reactors.

Advantages: Resists stress corrosion cracking in radioactive environments.

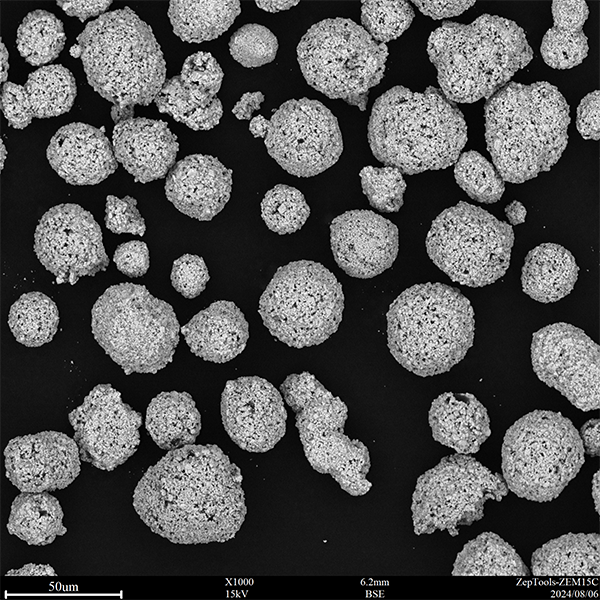

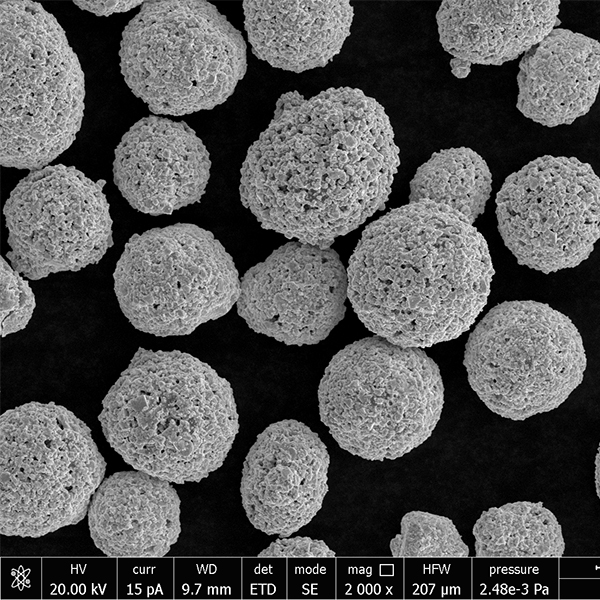

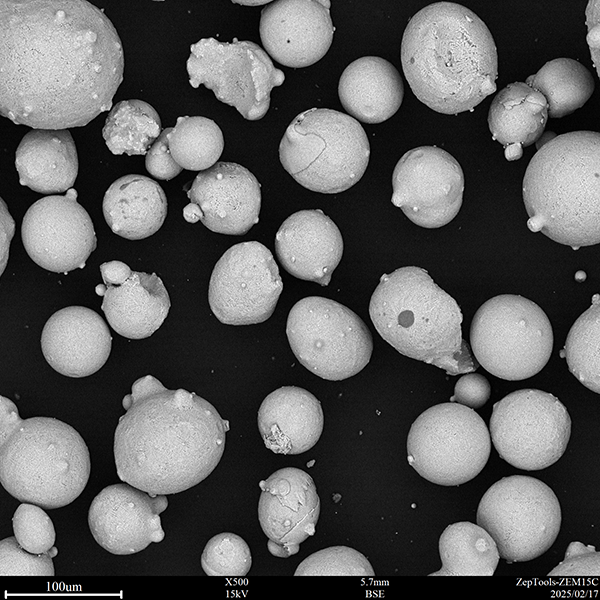

Powder Characteristics & Process Compatibility

Physical Properties:

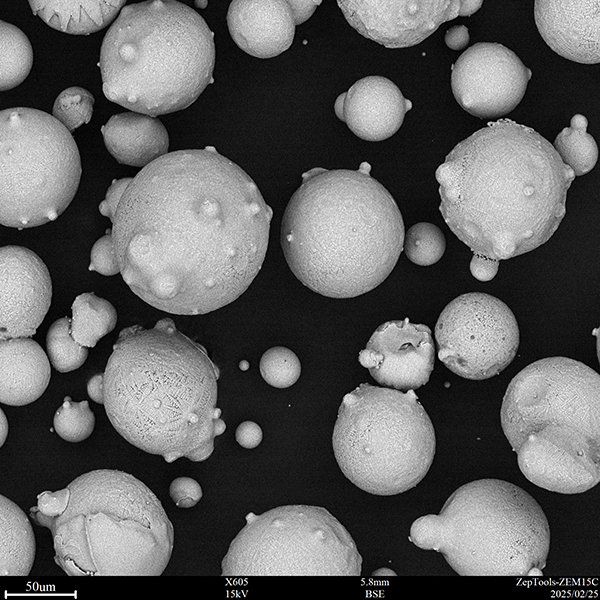

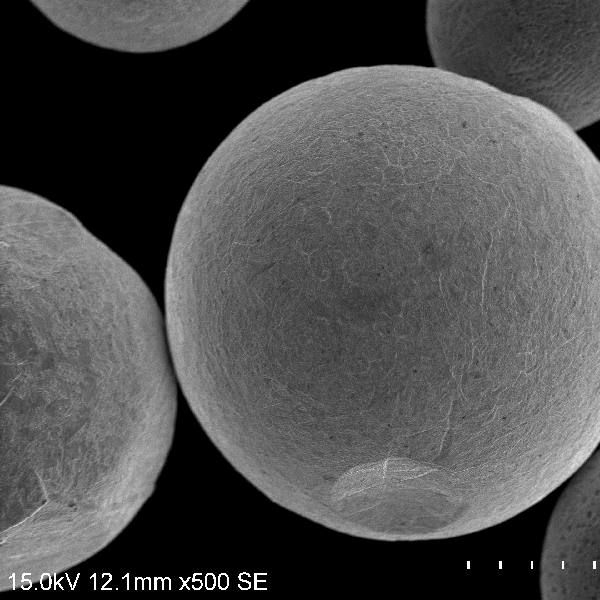

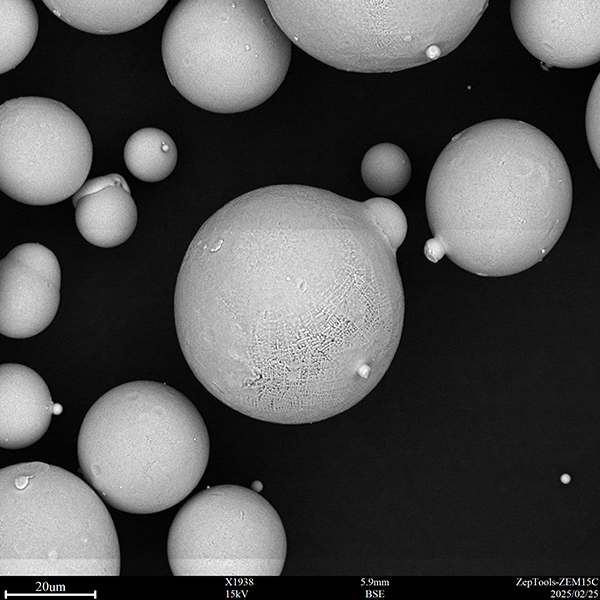

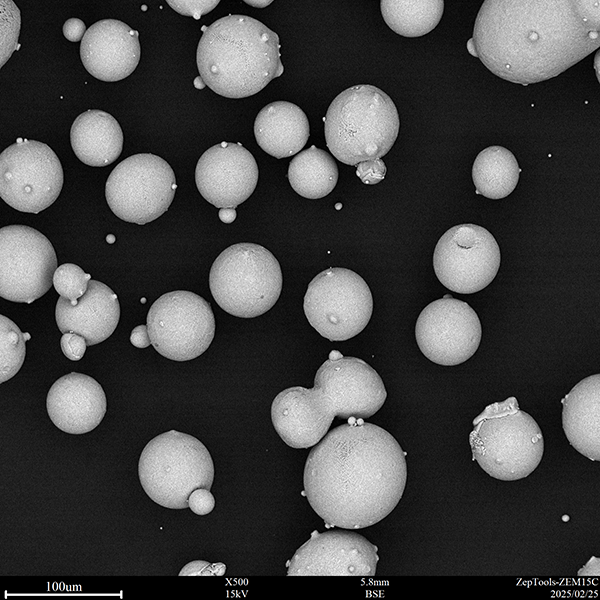

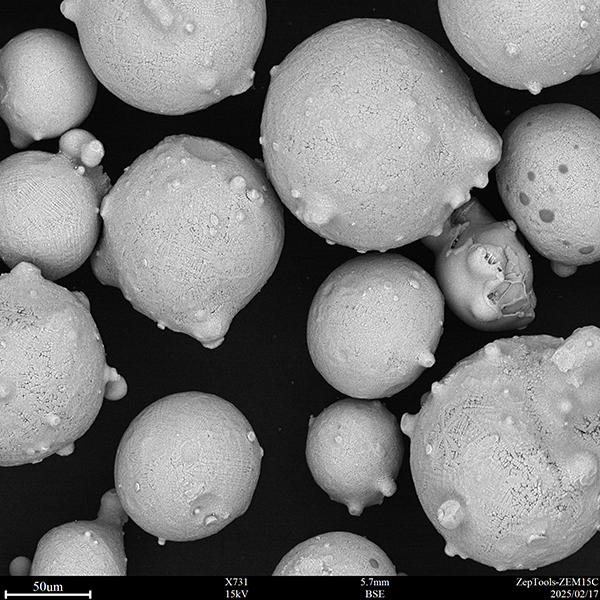

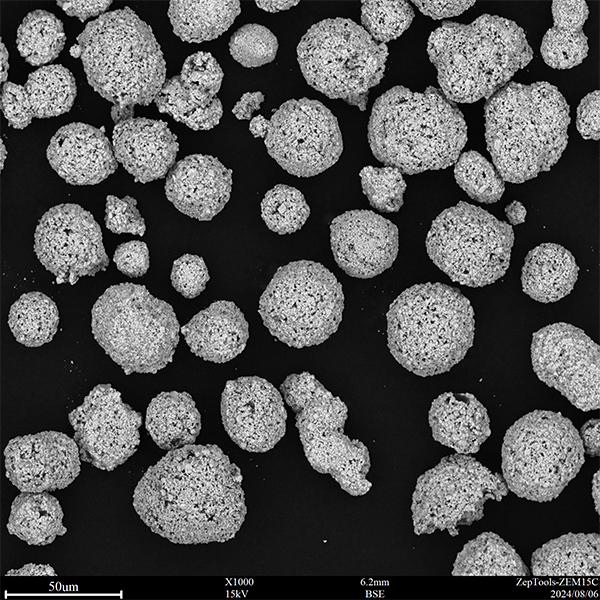

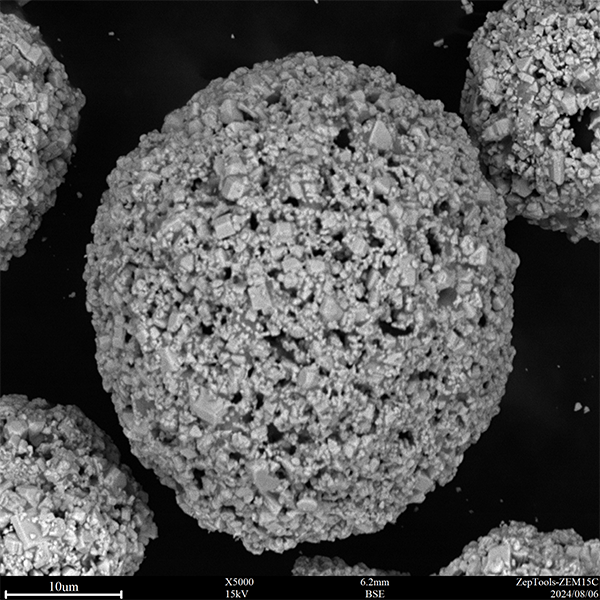

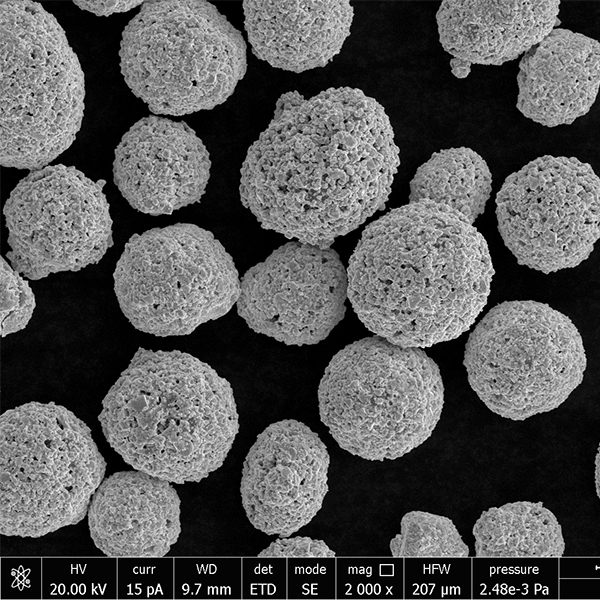

Particle size: 15–53 μm (powder-fed laser cladding) or 53–150 μm (coaxial powder feeding).

High sphericity: Ensures uniform flow and dense, pore-free cladding layers.

Process Advantages:

- Low heat input minimizes substrate distortion, suitable for thin-walled repairs.

- Clad layer hardness: ~200–250 HV, adjustable via post-heat treatment.

Comparison with Other Materials

vs. 304 Stainless Steel: 316L’s molybdenum content provides superior chloride resistance (e.g., seawater, bleach).

vs. Nickel-Based Alloys (e.g., Inconel): Lower cost but weaker high-temperature strength; ideal for moderate-temperature corrosive environments.

Summary

Stainless steel 316L powder, with its balanced corrosion resistance, workability, and cost efficiency, is ideal for laser cladding in complex corrosive environments. It is widely used in industrial repair and surface enhancement where performance and economy must coexist.

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.