Ni220M1 Glass Mold Cladding Powder – Redefining New Standards for Efficient Manufacturing

Performance characteristics

Precision Process, Consistent Reliability

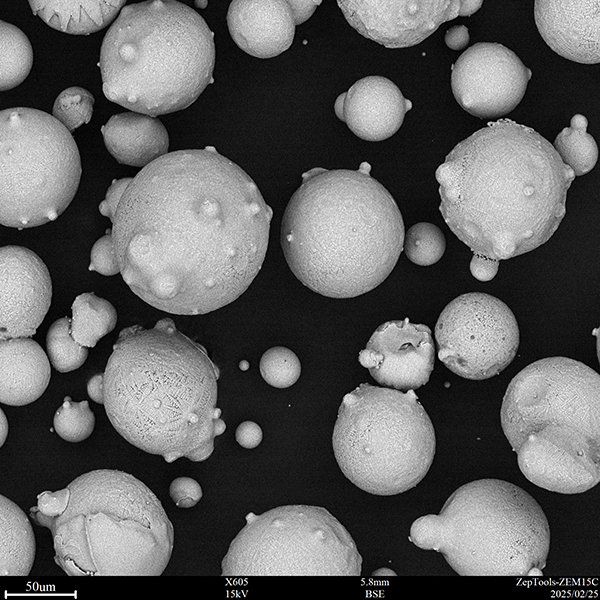

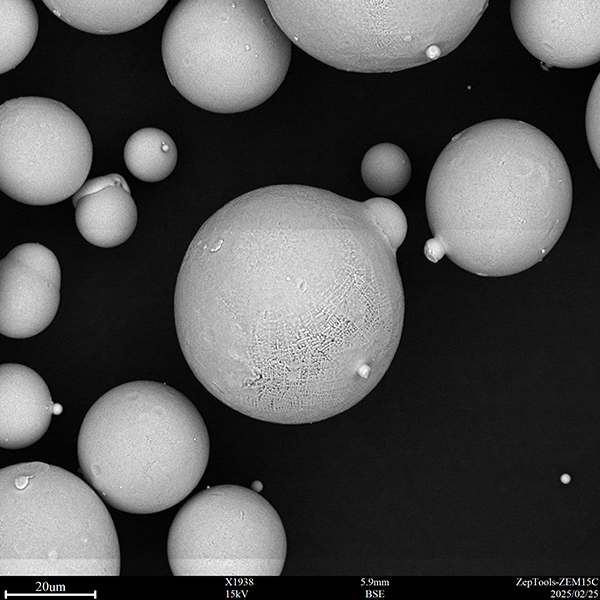

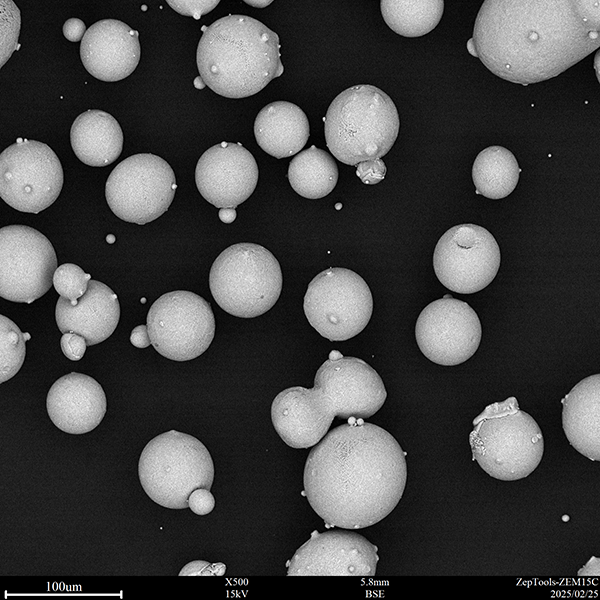

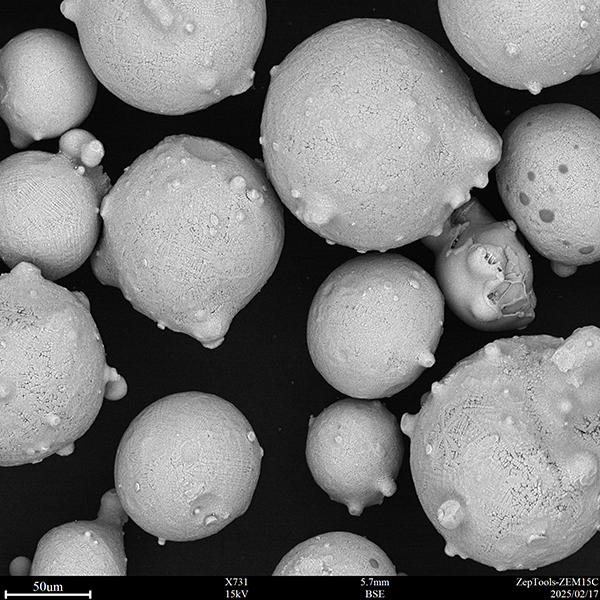

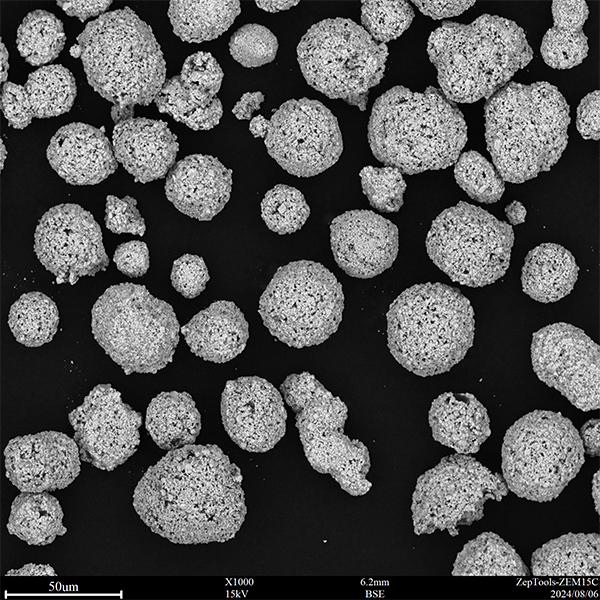

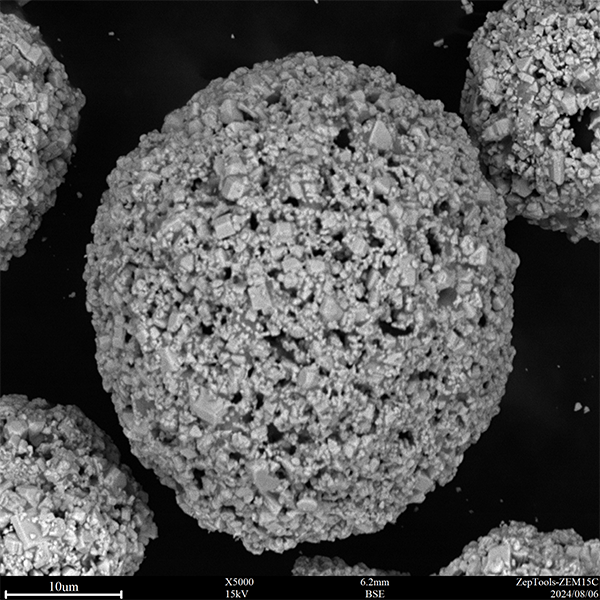

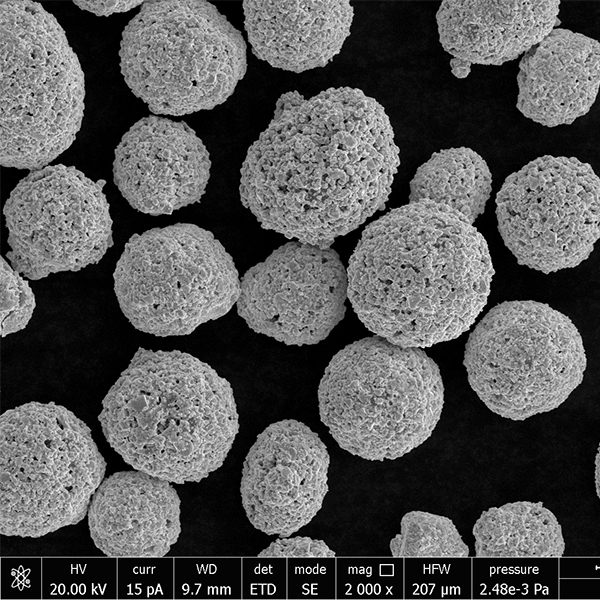

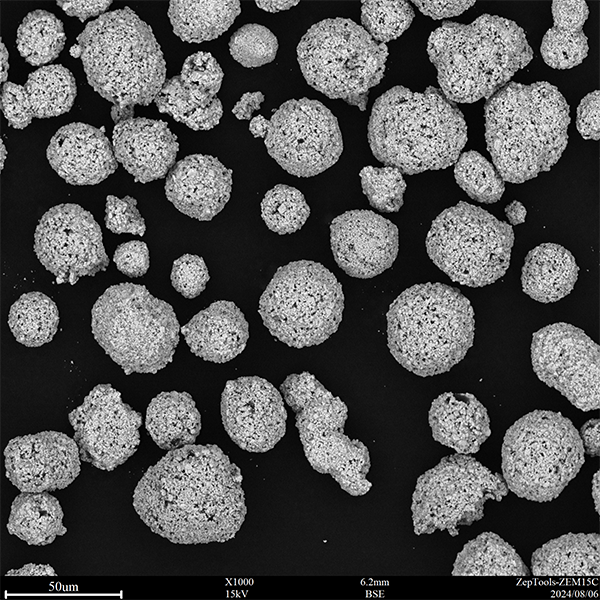

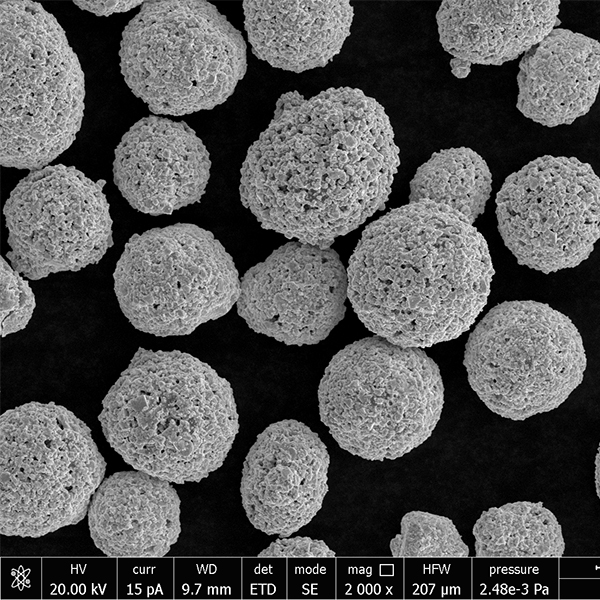

Utilizing high-temperature smelting at 1650-1700°C and 99.999% pure argon gas atomization, the process eliminates compositional segregation. The powder’s 45-150μm (100-325 mesh) particle size distribution ensures high sphericity and flowability (apparent density: 4.2g/cm³, flow rate: 14-16s/50g), providing stable powder feeding for plasma transferred arc welding (PTAW) and laser cladding processes.

Optimal Balance, Long-Term Durability

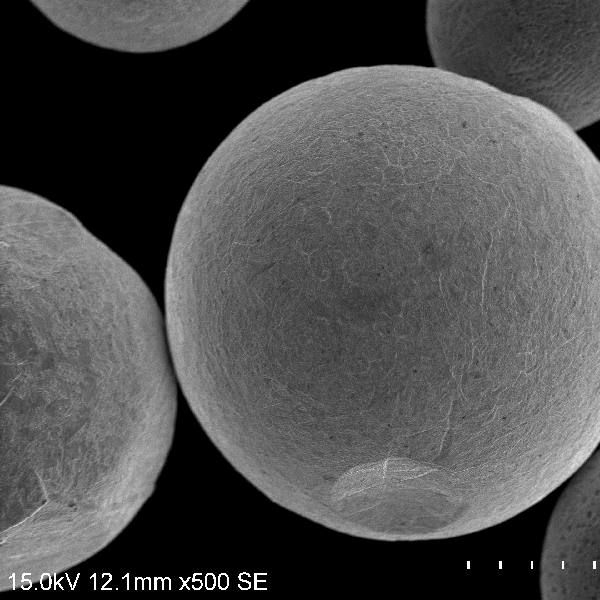

The innovative composition (C 0.03%, Cr 4.9%, B 1.0%, Si 3.0%) maintains low hardness (HRC 22-24) and exceptional ductility while forming erosion-resistant phases against molten glass. Post-polishing, the cladding layer achieves defect-free surfaces (zero pinholes/porosity). Enhanced metallurgical bonding through Fe-Mn element optimization triples mold service life.

Efficient Compatibility, Green Manufacturing

Adaptable to both high-speed large-area PTAW deposition and precision laser cladding repairs, the low heat input minimizes substrate deformation. With material utilization exceeding 95%, it enables energy-efficient production of durable mold working surfaces, significantly reducing maintenance costs.

Choosing Ni220M1 means securing dual guarantees of high-quality output and sustainable production, injecting innovative momentum into the glass manufacturing industry!

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.