What are the main applications of the welding layer of cobalt-based self-fluxing alloy?

Cobalt-based self-fluxing alloy welding layers (such as Stellite series) are widely used in the reinforcement and repair of key components under extreme working conditions due to their excellent high-temperature wear resistance, corrosion resistance and red hardness. The following are typical application areas:

- High-temperature wear-resistant parts

Aircraft engine blades: resist high-temperature gas erosion and particle erosion.

Gas turbine sealing rings: prevent high-temperature deformation and wear.

Internal combustion engine exhaust valves: resist high-temperature oxidation and ablation.

- Strong corrosive environment

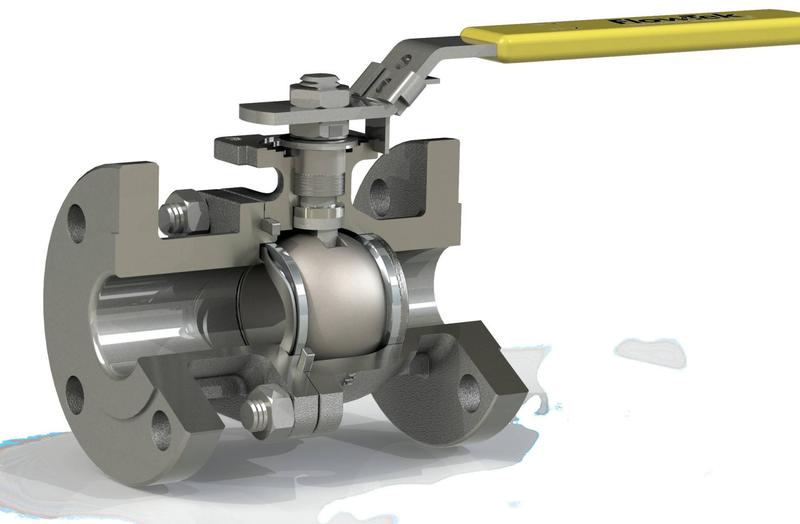

Chemical pump valve sealing surface: resist acid, alkali and liquid metal corrosion.

Nuclear power valves: withstand medium corrosion in radiation environment

- Heavy-load wear conditions

Rolling mill guide plate: withstand high-temperature billet friction.

Mining crusher roller teeth: resist ore impact and abrasive wear.

Cement kiln scraper: reduce clinker particle wear.

- Special industrial needs

Glass molds: prevent molten glass from adhering and high-temperature oxidation.

Hot shear tools: maintain cutting edge hardness at high temperatures.

- Repair and remanufacturing

Turbine blade repair: restore damaged parts in high-temperature areas.

High-value shaft repair: such as regeneration of worn parts of ship crankshafts.

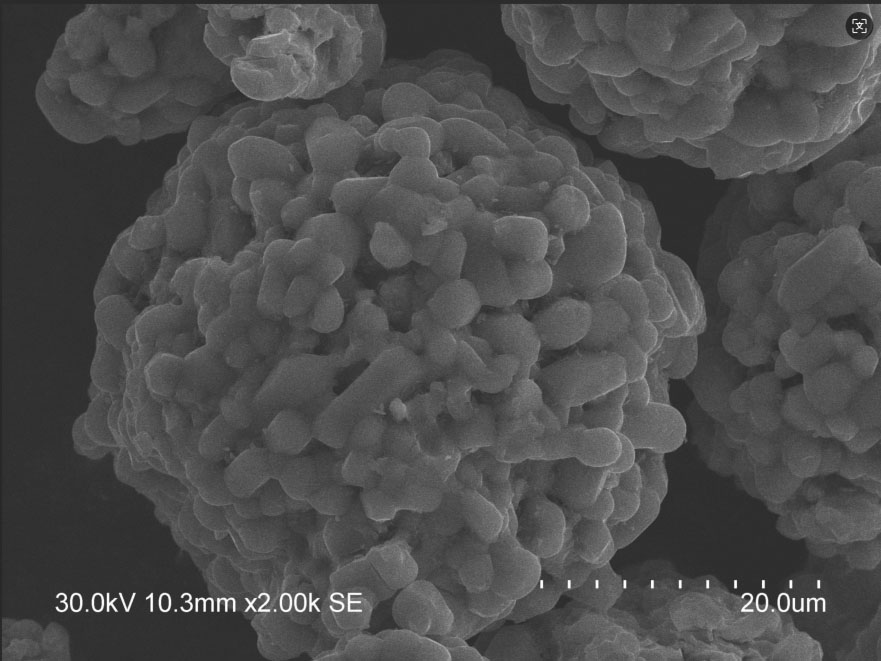

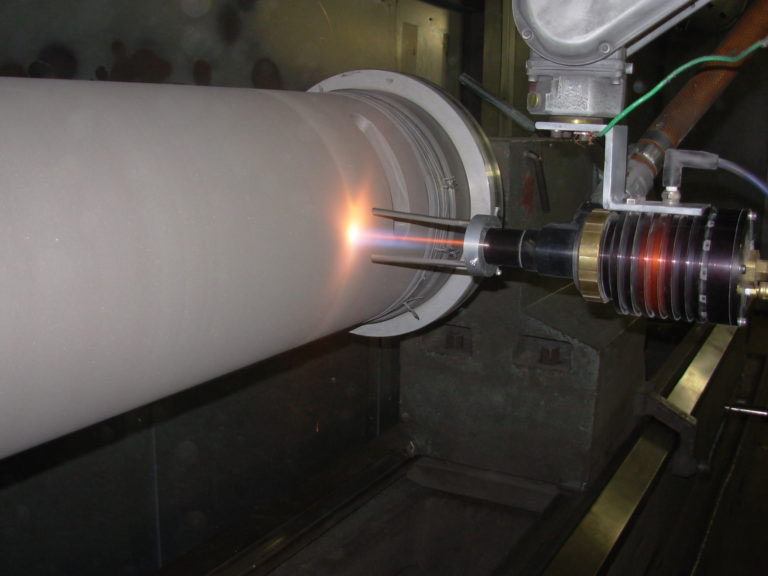

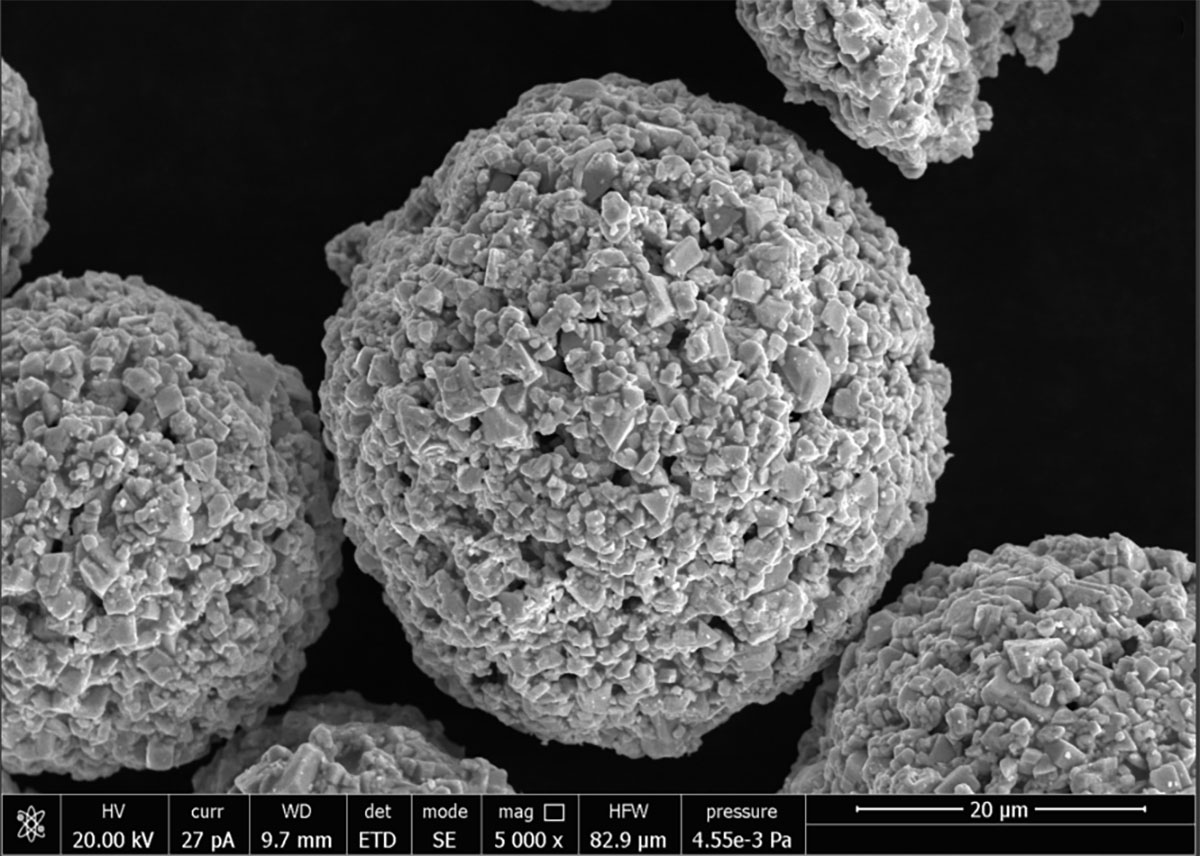

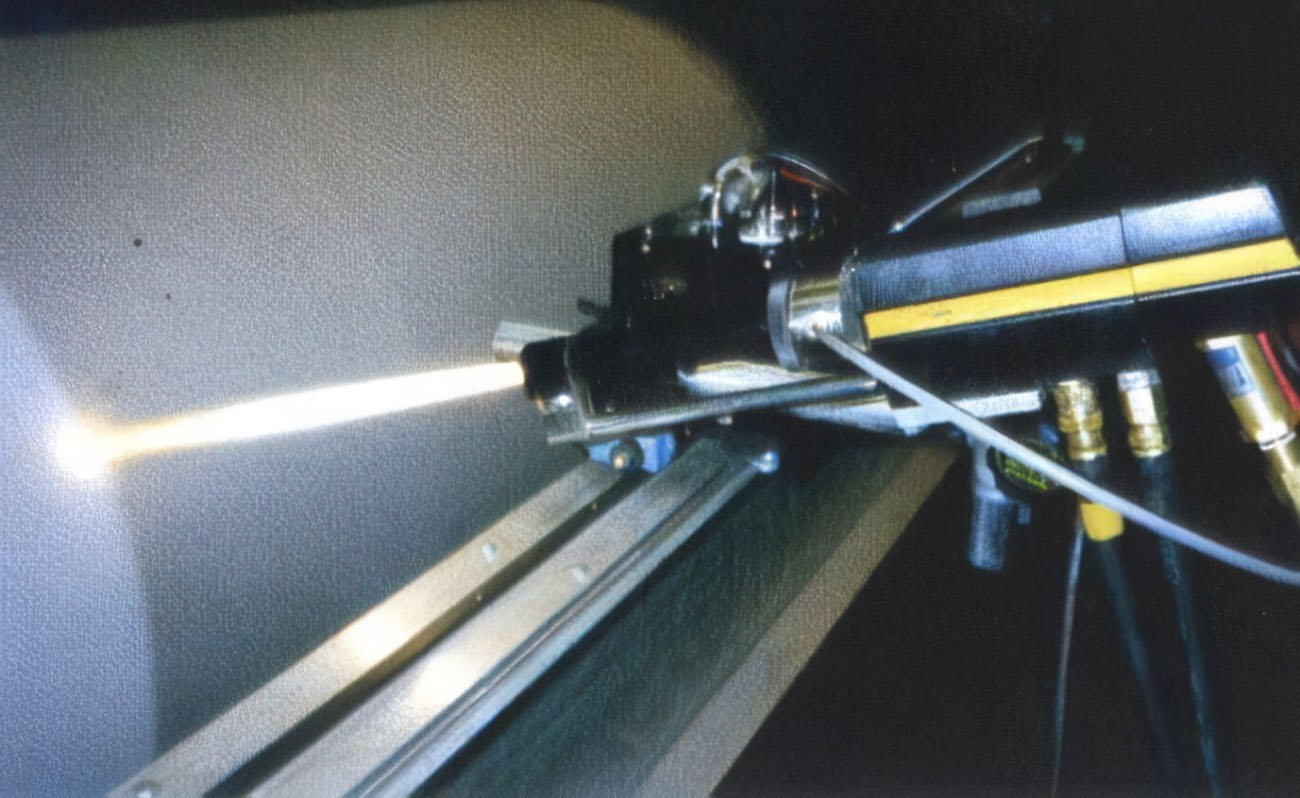

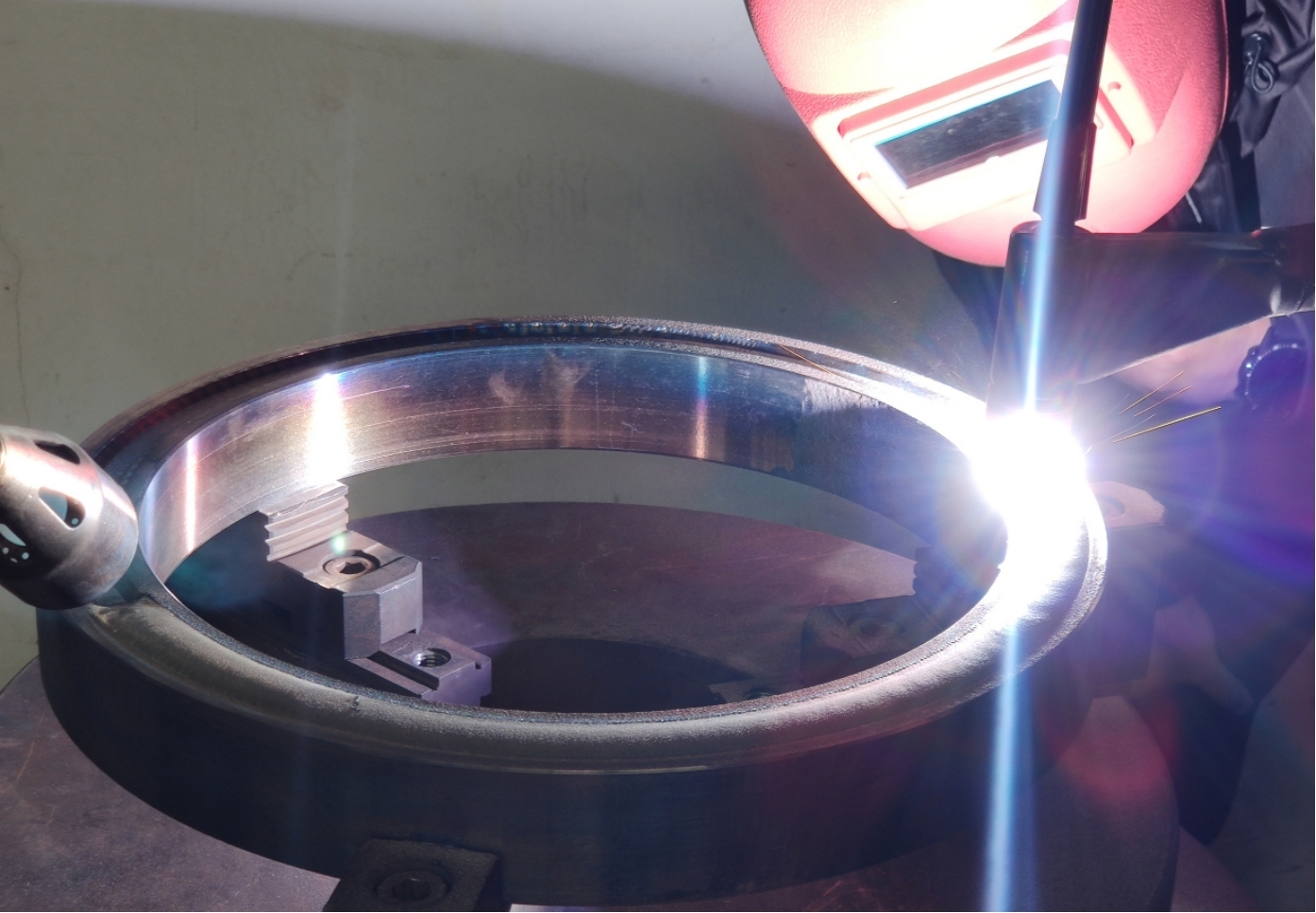

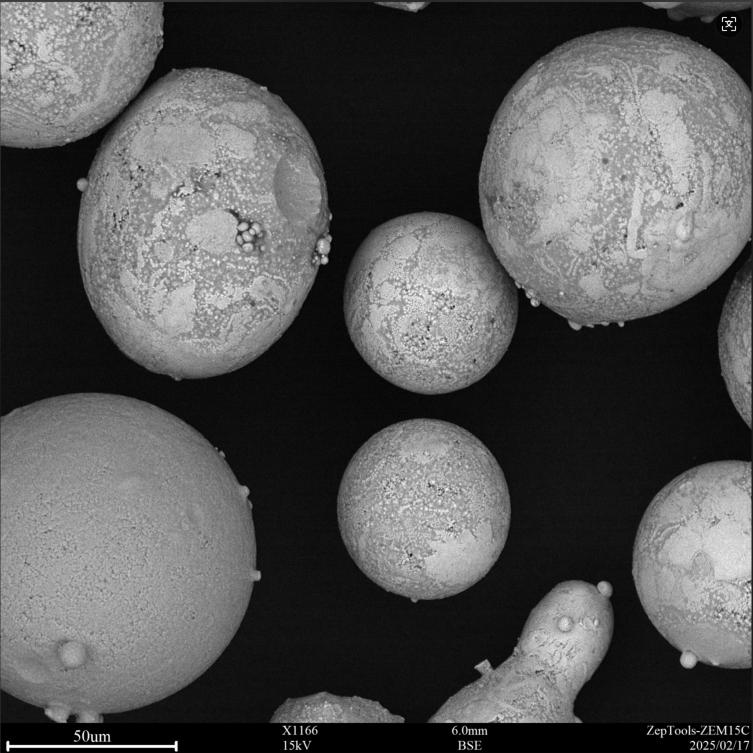

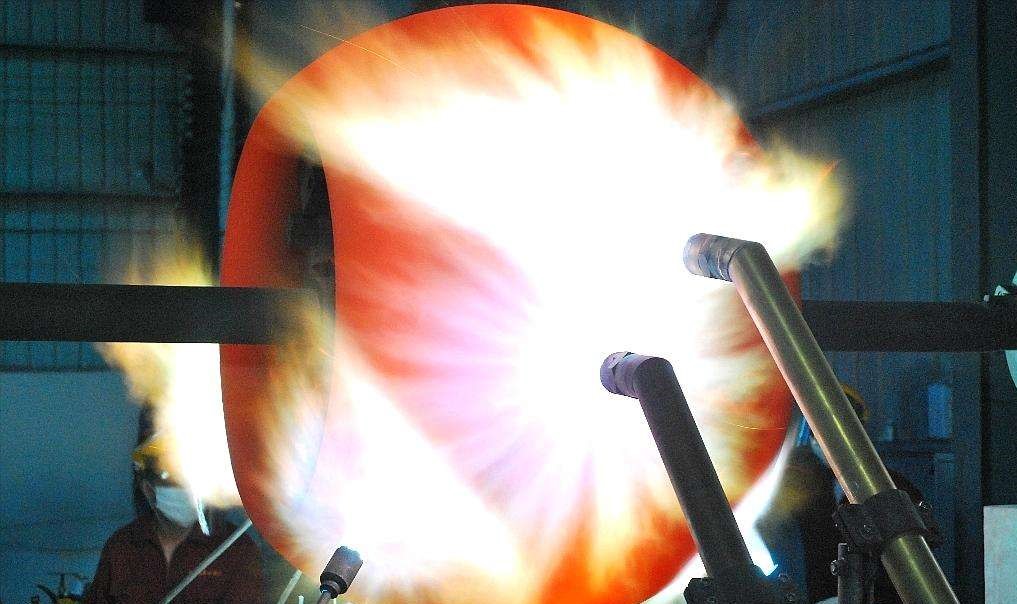

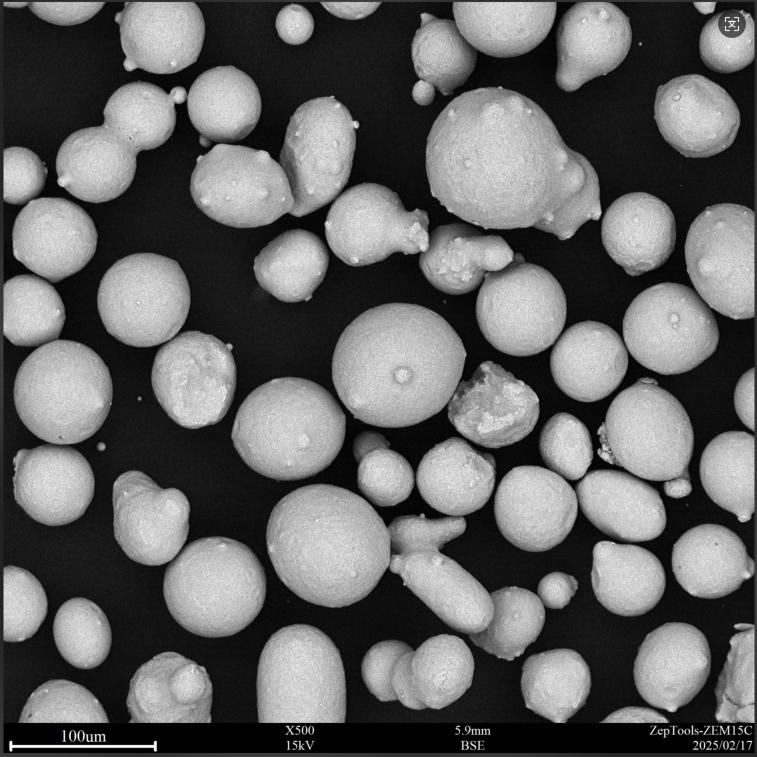

This type of welding layer usually uses plasma spray welding, laser cladding or TIG surfacing technology, which is particularly suitable for demanding scenarios that require high-temperature strength, corrosion resistance and wear resistance at the same time.