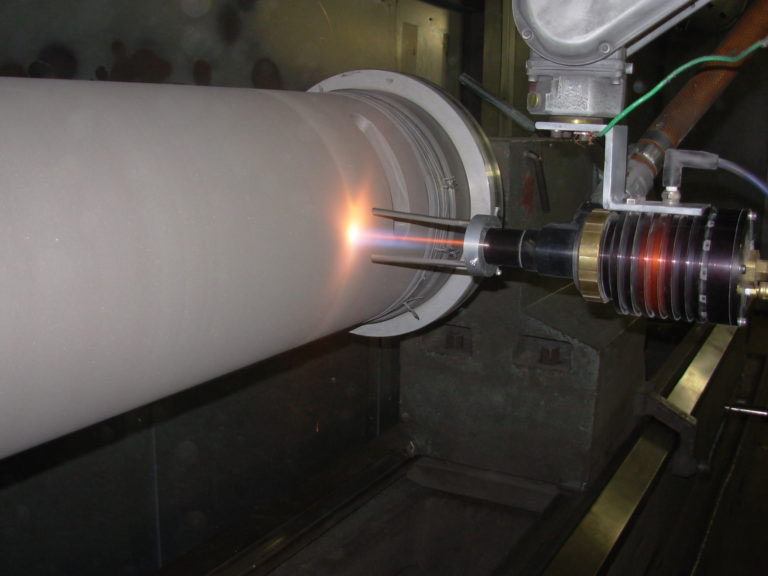

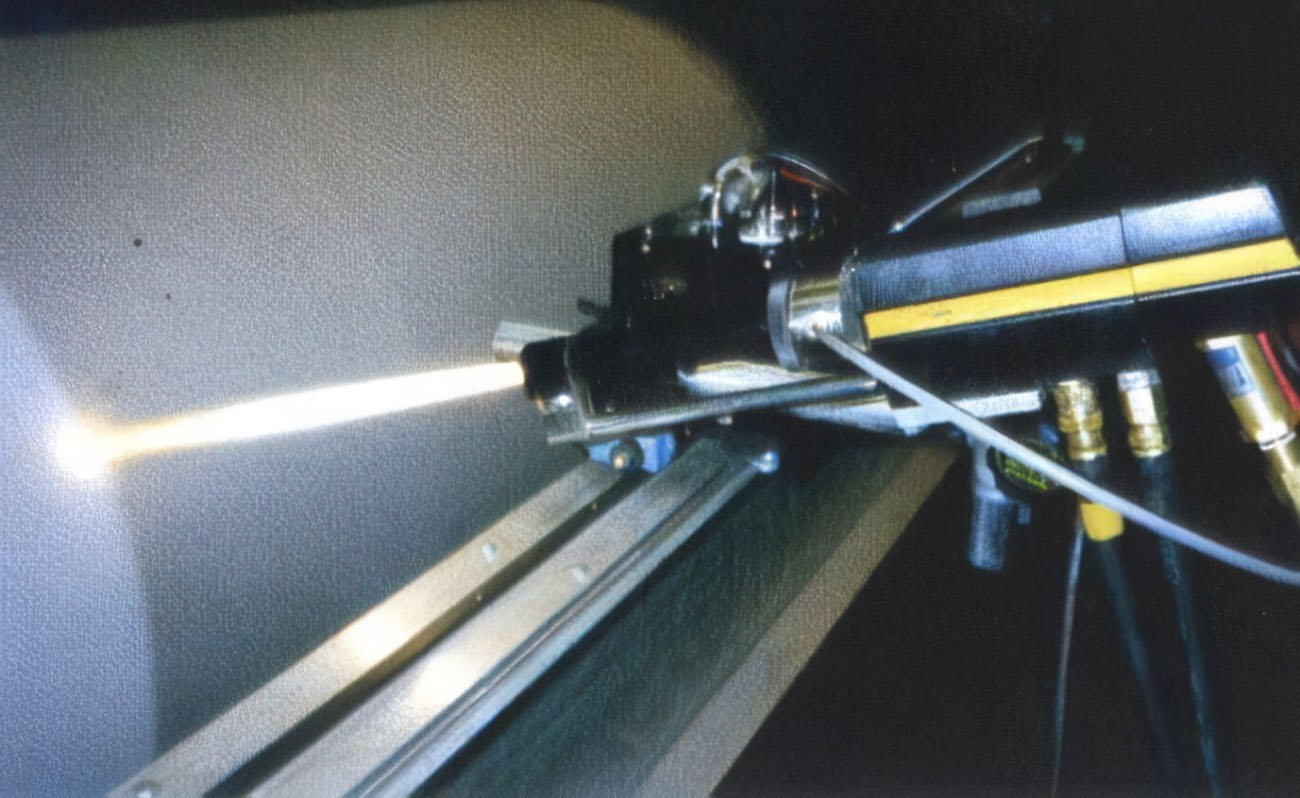

What are the applications of HVOF nickel-chromium carbide?

HVOF nickel-chromium carbide (NiCr-Cr3C2) coatings are widely used in the following fields due to their high hardness, excellent high-temperature wear resistance and oxidation resistance:

- High-temperature wear protection

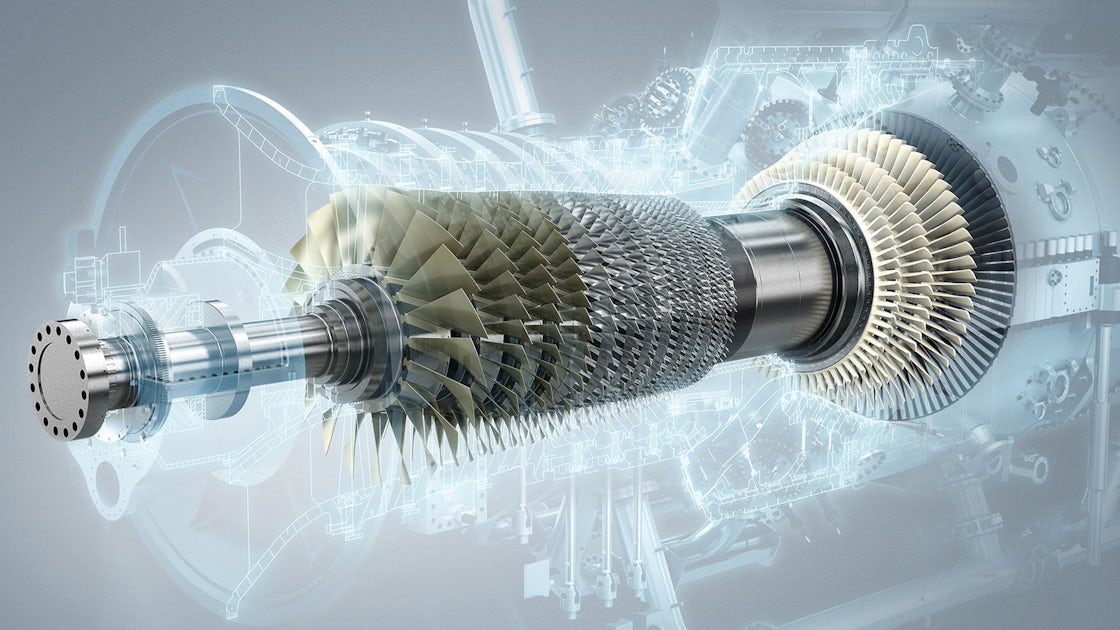

Aircraft engine parts: turbine blades, combustion chamber linings, etc., to resist high-temperature airflow scouring and particle erosion.

Gas turbine blades: improve thermal shock resistance and high-temperature oxidation resistance.

- Chemical and energy equipment

Boiler pipelines: prevent high-temperature flue gas corrosion and fly ash wear in coal-fired power plants.

Heat exchanger parts: reduce high-temperature sulfide and chloride corrosion.

Nuclear power valves: enhance radiation resistance and medium corrosion resistance.

- Oil and gas industry

Drilling tools: such as drill pipe joints and valves, to resist wear and corrosion of sand-containing fluids.

Downhole tools: improve durability in high-temperature and high-pressure environments.

- Metallurgy and heavy machinery

Roller surface strengthening: reduce wear and steel sticking during high-temperature rolling.

Blast furnace parts: such as bells and chutes, resist high-temperature material erosion.

- Automobile and rail transportation

Engine exhaust parts: such as turbocharger housings, resistant to high-temperature exhaust gas corrosion.

Braking system components: improve wear resistance and thermal fatigue resistance.

- Other industrial applications

Glass molds: prevent molten glass from adhering and high-temperature oxidation.

3D printing hot end nozzles: reduce wear of high-temperature metal powders.

The coating is particularly suitable for high-temperature wear, corrosion or oxidation environments below 800°C, and can significantly extend the life of key components.