Processing Characteristics and Applications of Laser Cladding

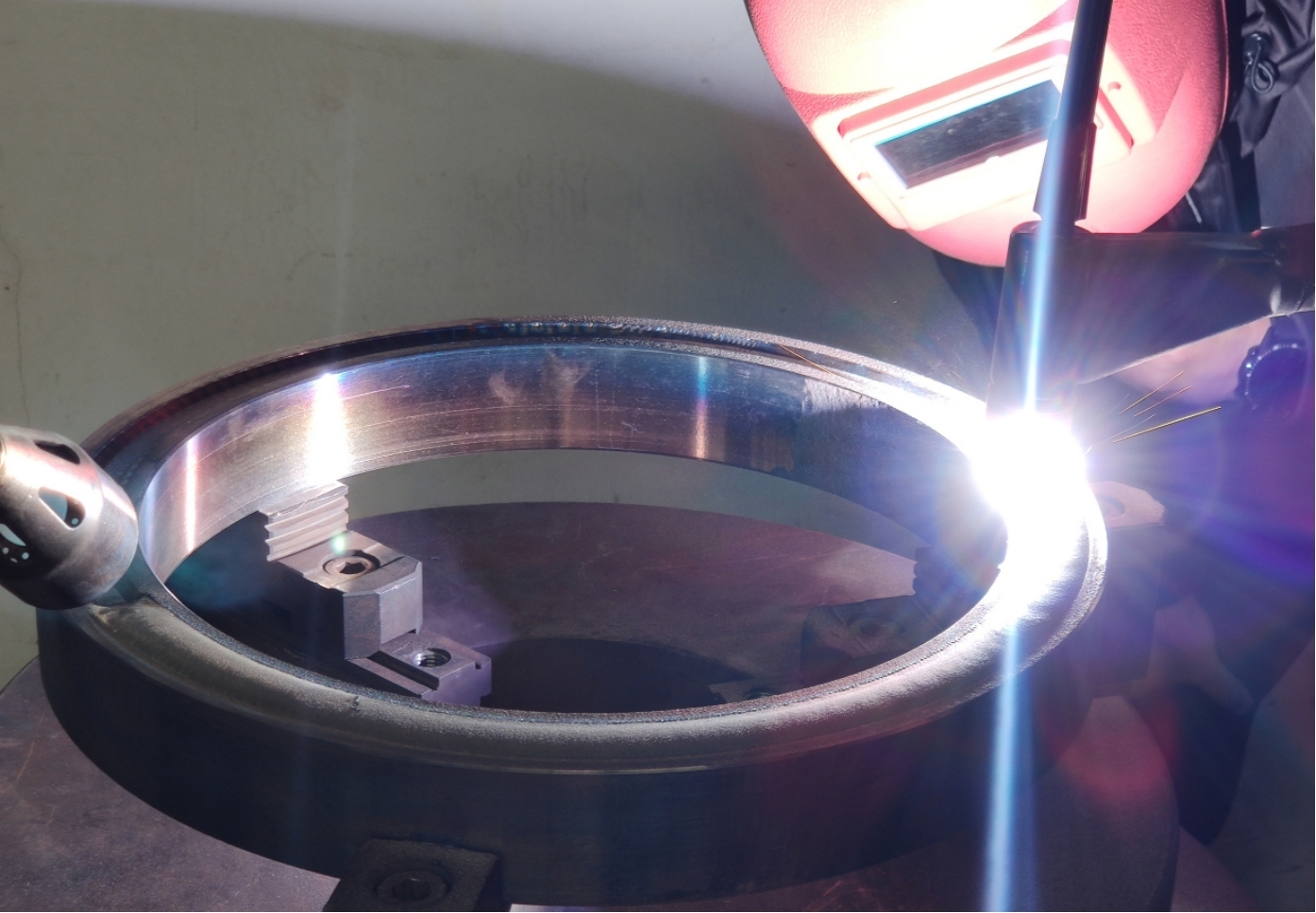

Laser Cladding: Processing Characteristics and Applications

Laser cladding technology is an advanced surface treatment technique widely used for the repair and enhancement of metal materials. Its core principle involves utilizing the high energy density of lasers to melt powder materials and bond them with the substrate, thereby forming a cladding layer with excellent properties. The selection of laser cladding powders is crucial for the performance of the cladding layer, which is mainly divided into three types: self-fusing powders, ceramic powders, and composite powders. Among these, self-fusing powders are widely used due to their excellent cost-performance ratio and broad applicability.

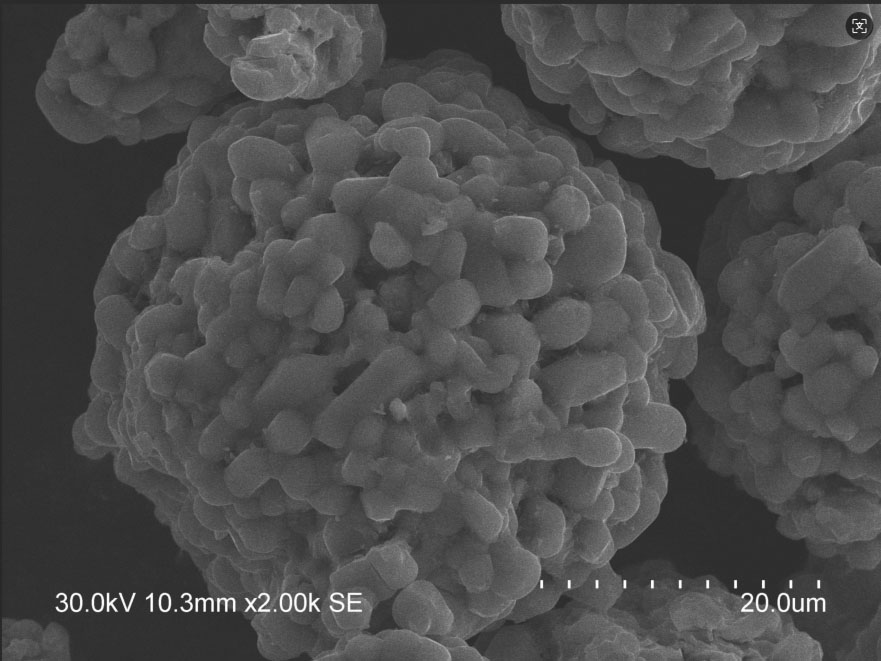

I. Self-Fusing Powders

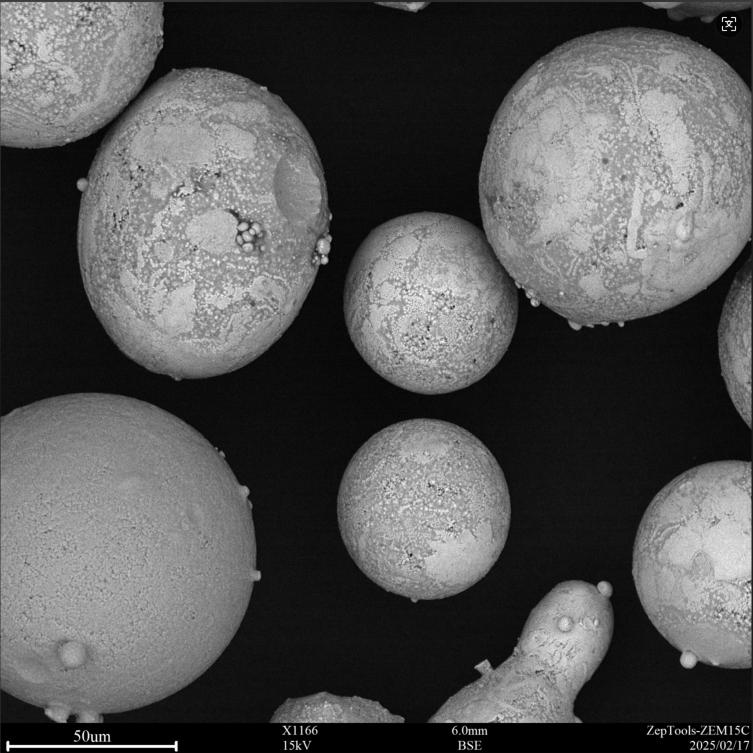

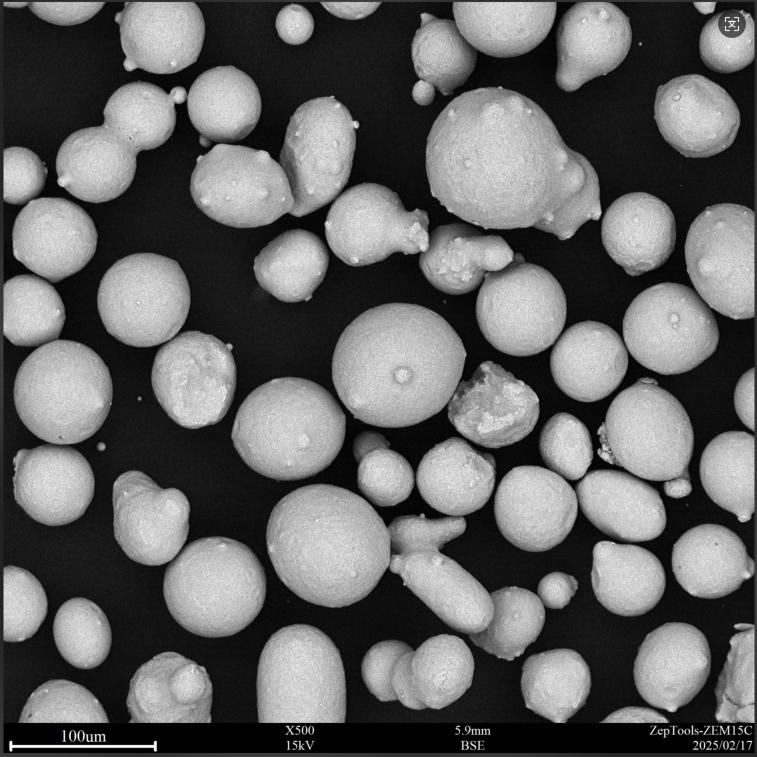

Self-fusing powders are the most commonly used type in laser cladding, primarily including iron-based alloy powders, nickel-based alloy powders, cobalt-based alloy powders, and copper-based alloy powders. These powders typically contain elements such as boron and silicon, which can form a good molten state during the cladding process, thereby enhancing the bonding strength and wear resistance of the cladding layer.

Iron-Based Alloy Powders

Iron-based self-fusing alloy powders are one of the most commonly used self-fusing powders. They are low in cost and have good wear resistance, making them suitable for various substrates, such as carbon steel, stainless steel, alloy steel, and cast steel. However, iron-based alloy powders also have some drawbacks, such as susceptibility to oxidation and cracking. By adjusting the powder composition, these drawbacks can be effectively improved. For example, the appropriate addition of hard phases like tungsten carbide or titanium nitride can enhance the wear resistance and strength of the cladding layer.

Nickel-Based Alloy Powders

The cladding layer strength of nickel-based self-fusing alloy powders is relatively low, and they usually require the addition of other hard materials to improve their performance. Nickel-based alloy powders perform excellently in high-temperature and corrosive environments, making them suitable for aerospace and chemical industries. To enhance the performance of the cladding layer, tungsten carbide, titanium nitride, and other materials are often added to nickel-based alloys to improve their wear resistance and corrosion resistance.

Cobalt-Based Alloy Powders

Cobalt-based self-fusing alloy powders exhibit excellent heat resistance, corrosion resistance, wear resistance, impact resistance, and high-temperature oxidation resistance, making them suitable for applications in extreme conditions. Nickel-containing cobalt-based alloy powders can reduce the expansion coefficient of the cladding layer, thereby decreasing the occurrence of cracks and improving wettability and bonding strength.

Effects of Boron and Silicon

While self-fusing powders rely on boron and silicon, excessive amounts of these elements can also have negative effects. Boron and silicon have slag-forming properties, and an excess of slag can increase the risk of cracking in the cladding layer. Additionally, the carbon content in the alloy powders can enhance hardness and wear resistance, but too high a carbon content can increase the brittleness of the cladding layer. Therefore, when selecting self-fusing powders, it is essential to consider the content of each element comprehensively to achieve the best cladding effect.

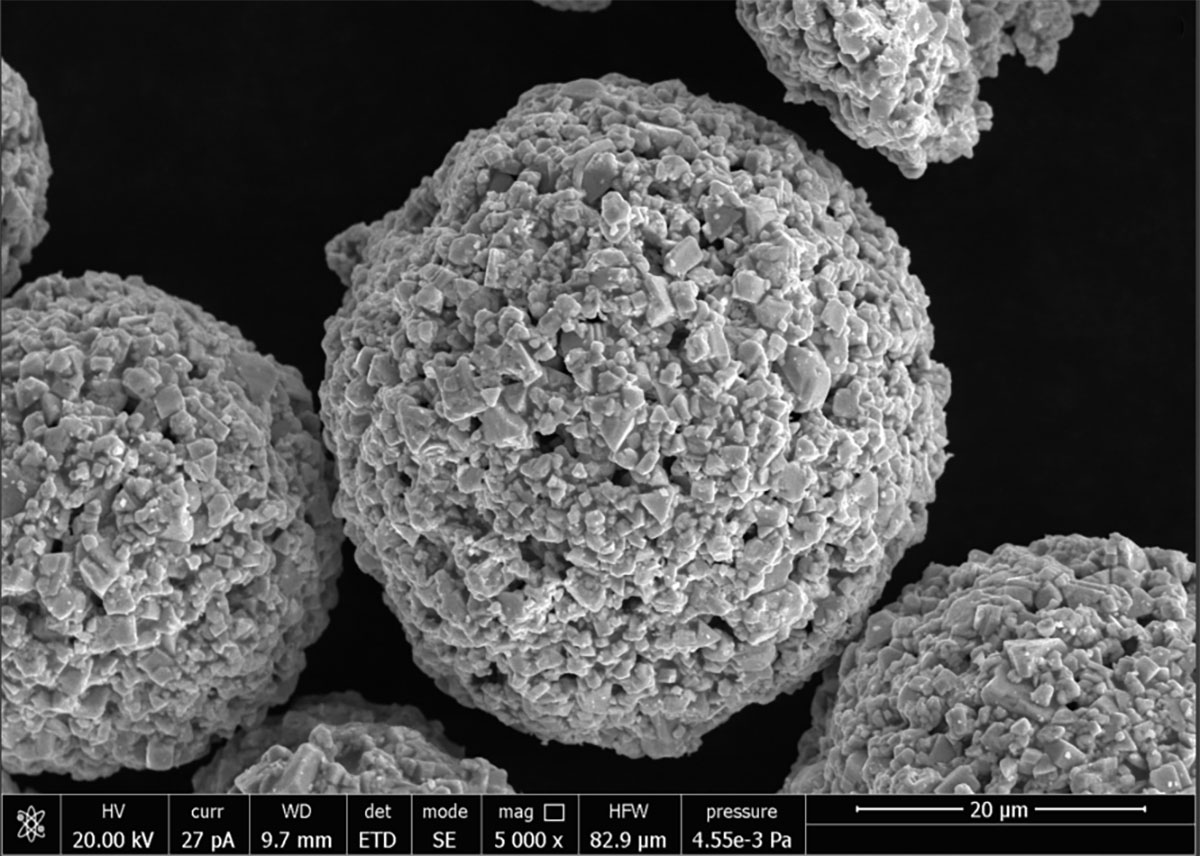

II. Ceramic Powders

Ceramic powders are primarily used in laser cladding to enhance the wear resistance, corrosion resistance, and high-temperature performance of the cladding layer. Common ceramic powders include zirconia and alumina. These ceramic materials play a reinforcing role in the cladding layer, effectively improving the service life of the materials.

Zirconia

Zirconia is an excellent ceramic material with high strength and good wear resistance. Its cladding layer can maintain stable performance in high-temperature and corrosive environments, making it widely used in aerospace, chemical, and mechanical manufacturing industries.

Alumina

Alumina is a commonly used ceramic material known for its excellent wear resistance and corrosion resistance. Its cladding layer can effectively protect the substrate and extend its service life. The cladding layer of alumina is typically used in applications requiring wear and corrosion resistance, such as mining machinery and chemical equipment.

III. Composite Powders

Composite powders are a new type of powder material formed by mixing ceramic powders with metal powders. The advantage of composite powders lies in their ability to combine the benefits of both metals and ceramics, resulting in cladding layers with excellent properties. Common composite powders include tungsten carbide and titanium nitride.

Tungsten Carbide

Tungsten carbide is a hard material with extremely high hardness and wear resistance. Mixing tungsten carbide with metal powders can significantly enhance the wear resistance and strength of the cladding layer. However, the addition ratio of tungsten carbide needs to be controlled, as a high ratio may lead to cracking in the cladding layer.

Titanium Nitride

Titanium nitride is an excellent ceramic material with good wear resistance and corrosion resistance. When mixed with metal powders, it can improve the overall performance of the cladding layer. Similar to tungsten carbide, the addition ratio of titanium nitride also needs to be moderate to avoid increasing the brittleness of the cladding layer.

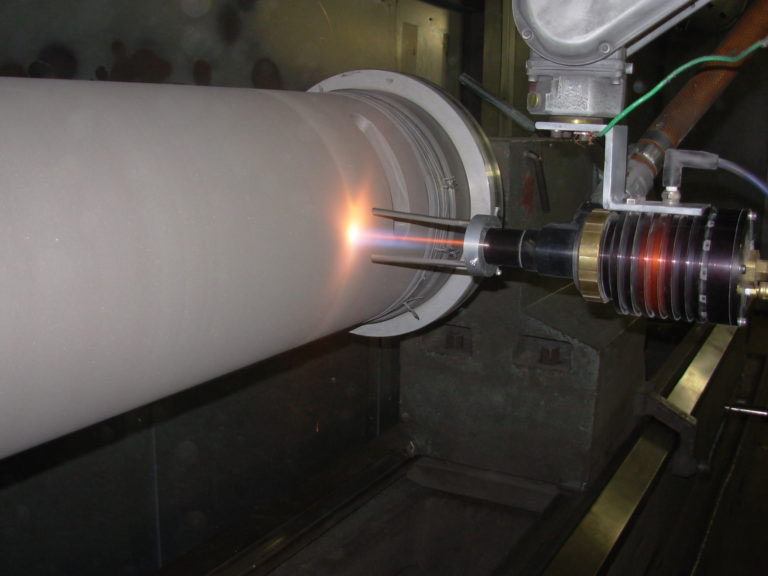

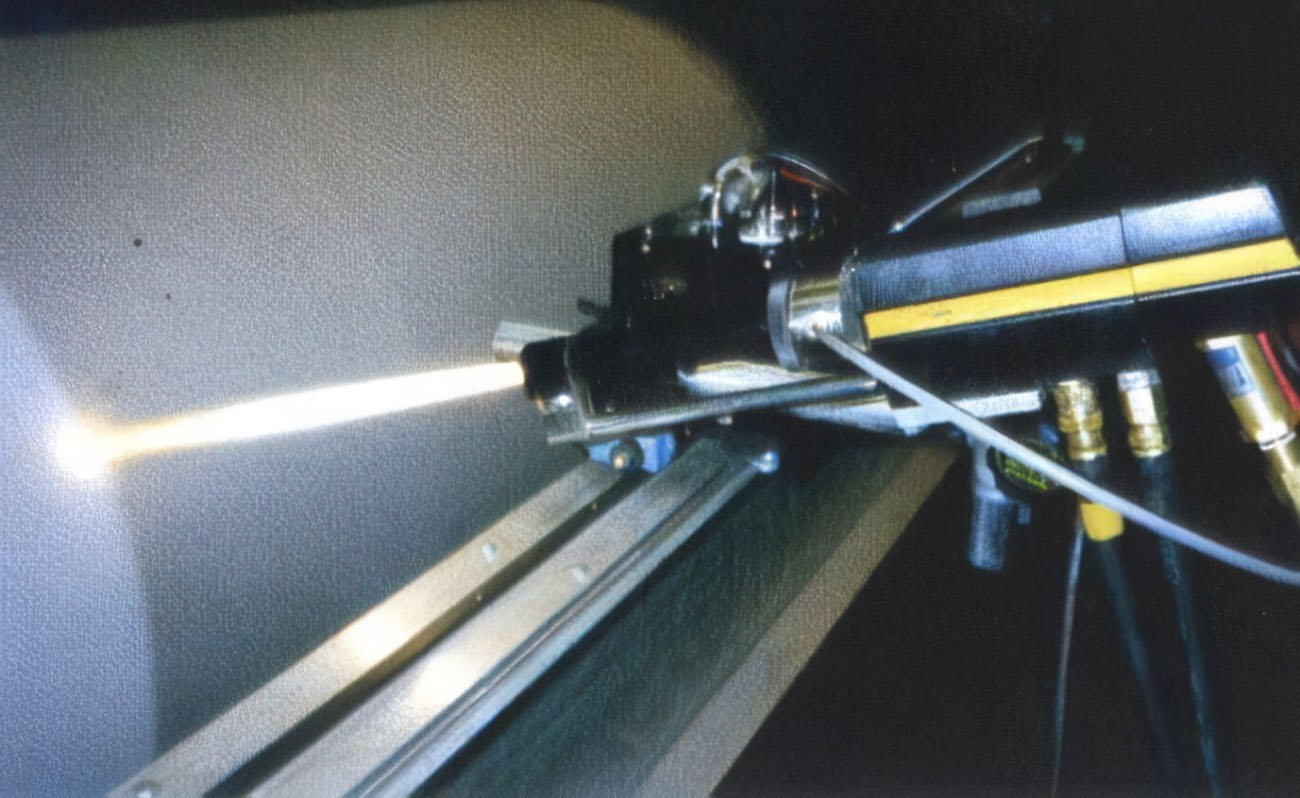

IV. Process Parameters

The process parameters of laser cladding have a significant impact on the quality and performance of the cladding layer. Preheating of the powder and substrate, the thickness of the cladding layer, laser power, scanning speed, and other factors need to be precisely controlled.

Preheating

During the laser cladding process, both the powder and the substrate typically need to be preheated, with a preheating temperature generally between 200-400°C. Preheating can reduce thermal stress in the materials and decrease the occurrence of cracks. After cladding, annealing is usually required to further reduce stress and control cracking.

Cladding Layer Thickness

The thickness of the cladding layer is usually controlled between 1.0-1.5mm, and the cladding trajectory should be slightly wider. If the cladding layer is too thick, it is prone to cracking, and having too many layers can also increase the risk of cracks. Therefore, in practical operations, it is necessary to adjust the thickness and number of cladding layers based on specific conditions.

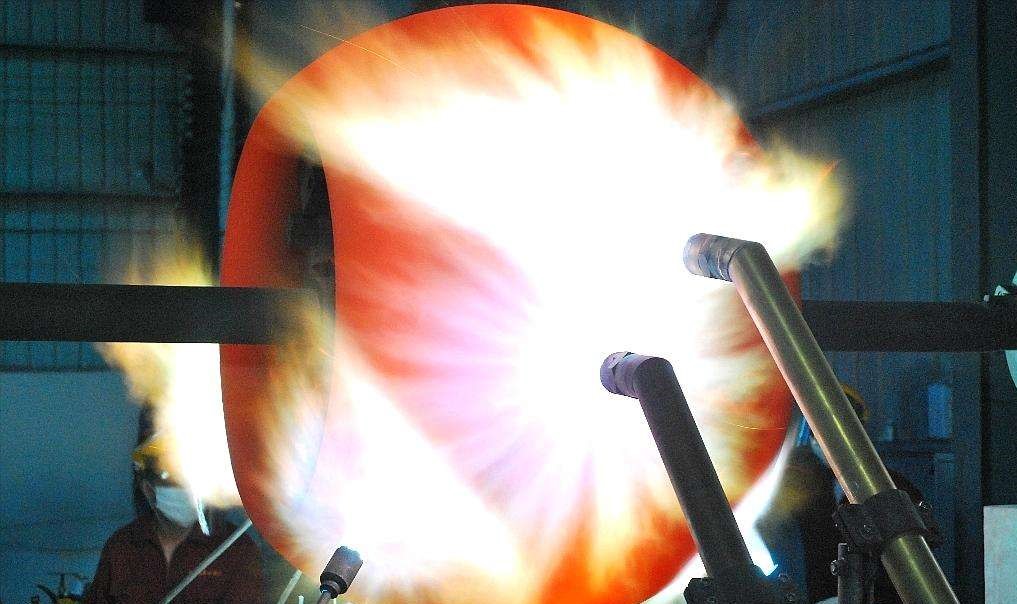

Laser Power and Scanning Speed

Increasing the laser power can reduce residual stress and the occurrence of cracks, but excessively high power may lead to other defects. Reducing the scanning speed can also decrease residual stress, but it is essential to balance cladding efficiency and quality. The appropriate powder feed rate is also crucial; an excessive feed rate can lead to increased layer thickness, insufficient melting of the powder, and the potential for voids and cracks.

Spot Shape

The shape of the laser spot also affects the quality of the cladding. Common spot shapes include circular, annular, rectangular, and linear. Circular spots have high energy in the center and low energy at the edges, suitable for applications requiring high energy density; annular spots have high energy at the edges and low energy in the center, suitable for large-area cladding; rectangular spots have uniform energy distribution, suitable for even cladding; and linear spots are suitable for wide cladding.

V. Conclusion

As an efficient surface treatment method, laser cladding technology has a broad range of application prospects. Selecting suitable powder materials and optimizing process parameters are key to ensuring the performance of the cladding layer. Self-fusing powders, ceramic powders, and composite powders each have their unique advantages and applicable ranges. A reasonable combination and application of these materials can significantly enhance the performance and service life of materials. In the future, with the continuous development of materials science and laser technology, laser cladding technology will demonstrate its unique advantages in more fields.