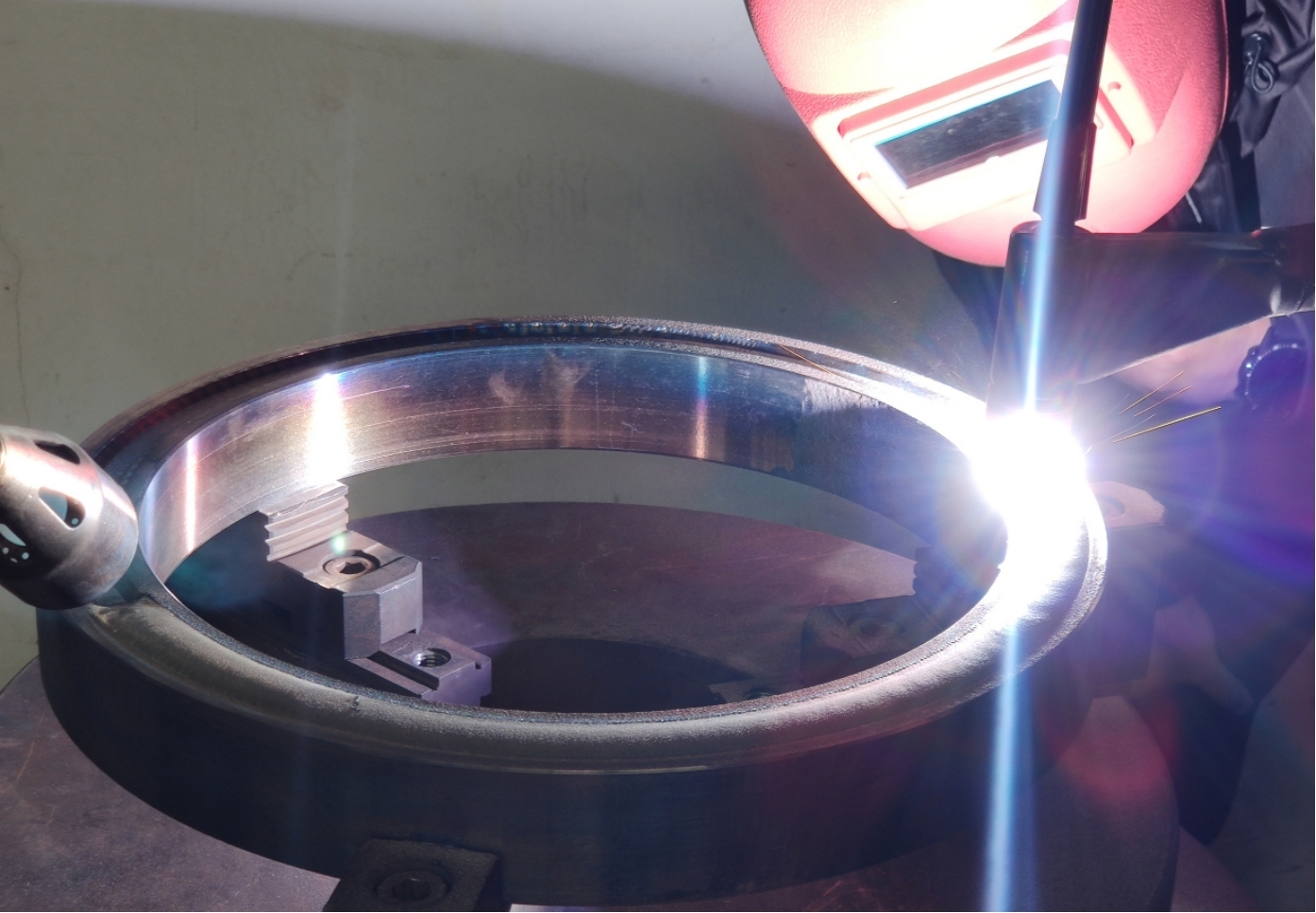

Primer used before plasma spraying ceramic powder

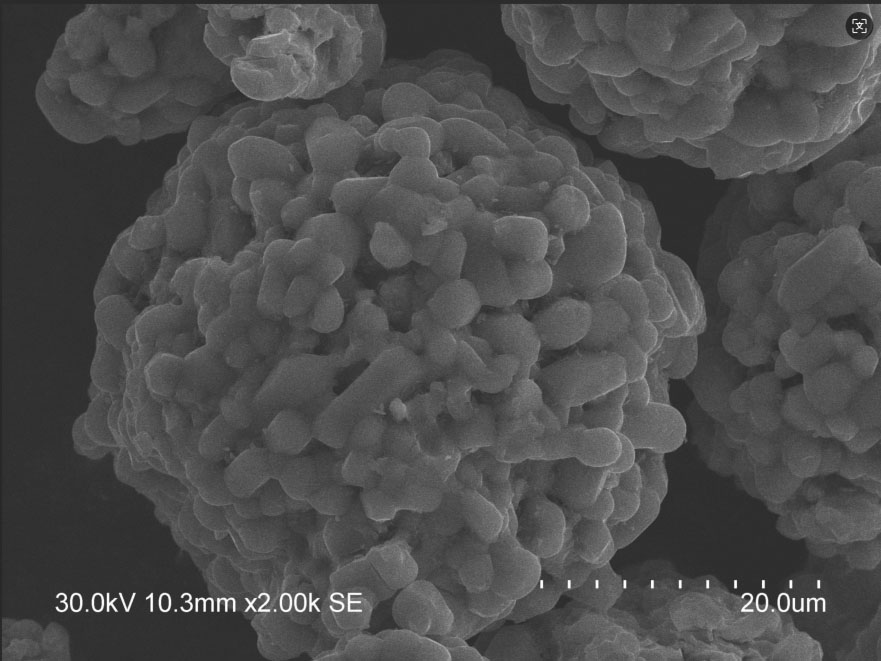

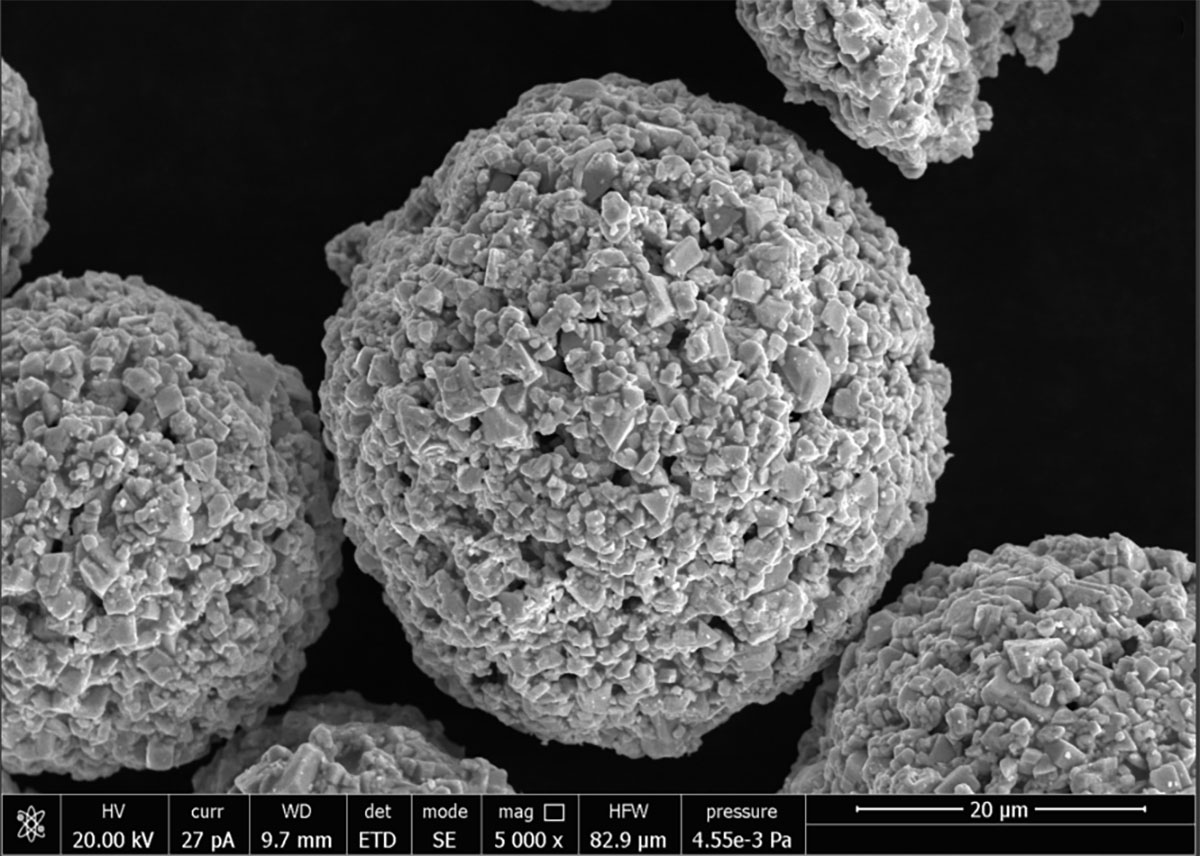

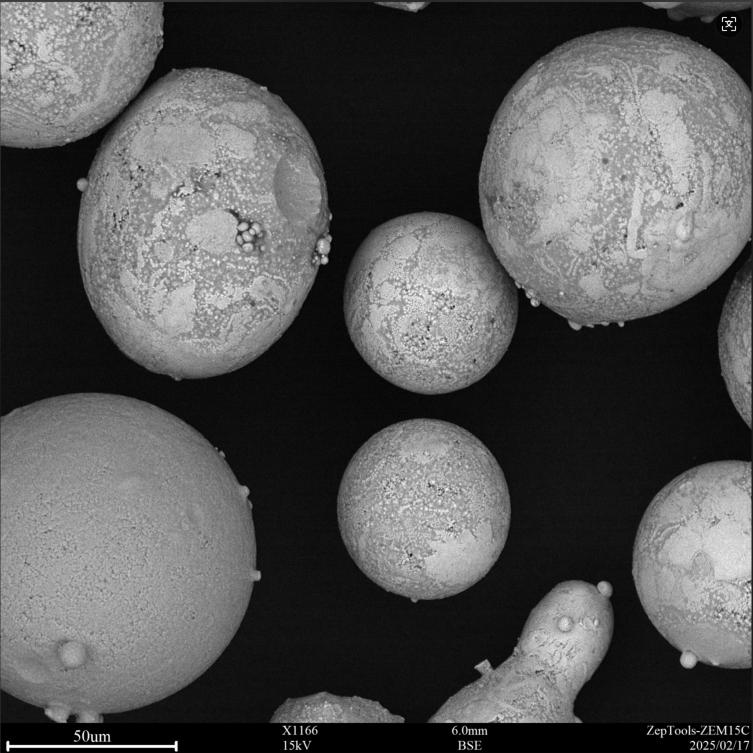

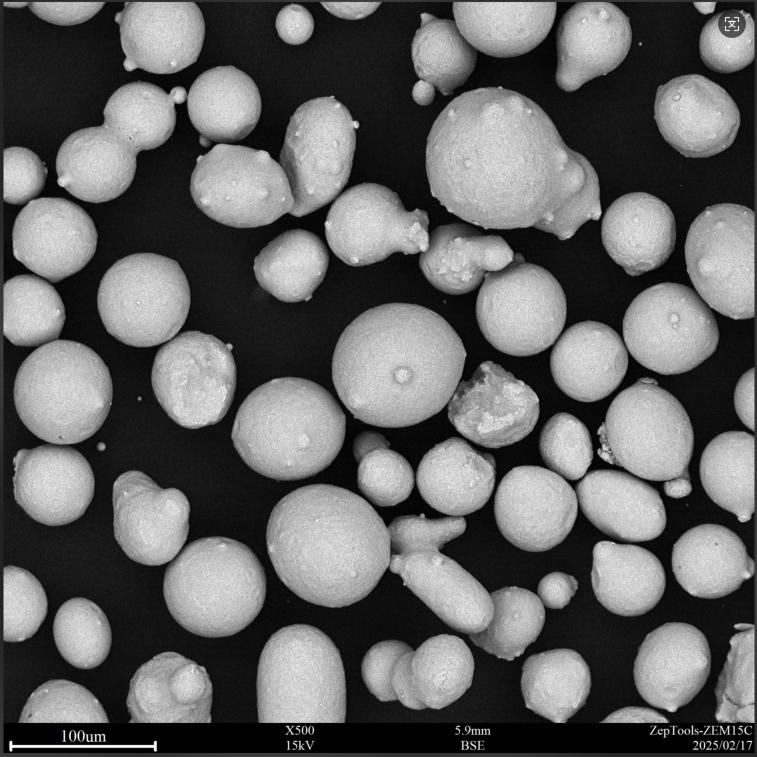

The nickel-chromium alloy primer used before plasma spraying ceramic coating is usually high-temperature alloy powder such as Ni80Cr20 or Ni70Cr30. Its main function is to enhance the bonding strength between the ceramic layer and the metal substrate and prevent the coating from cracking due to high-temperature oxidation and thermal expansion mismatch.

Main characteristics

- High bonding strength: Forms a strong metallurgical bond with common metal substrates such as steel and nickel-based alloys.

- Oxidation resistance: Chromium (Cr) forms a dense chromium oxide (Cr2O3) protective film at high temperatures to prevent further oxidation of the substrate.

- Thermal expansion transition: The thermal expansion coefficient of nickel-chromium alloy is between that of the metal substrate and the ceramic coating, reducing the risk of thermal stress cracking.

Typical application scenarios

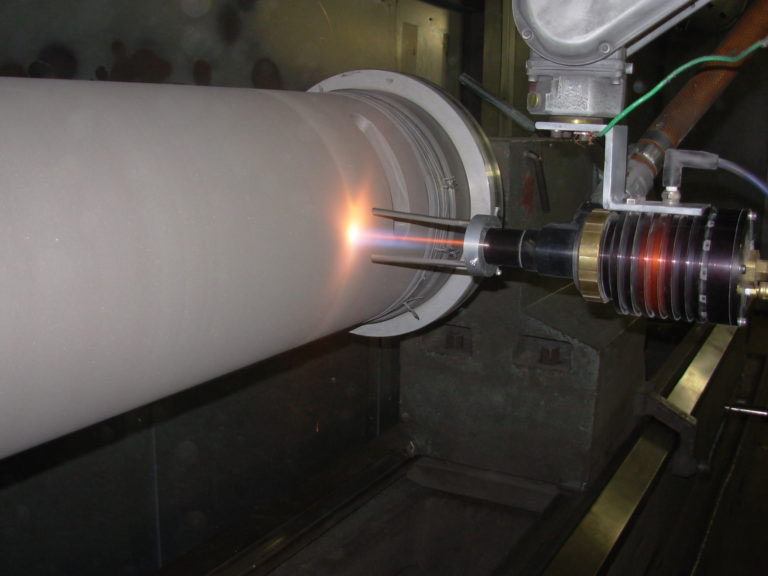

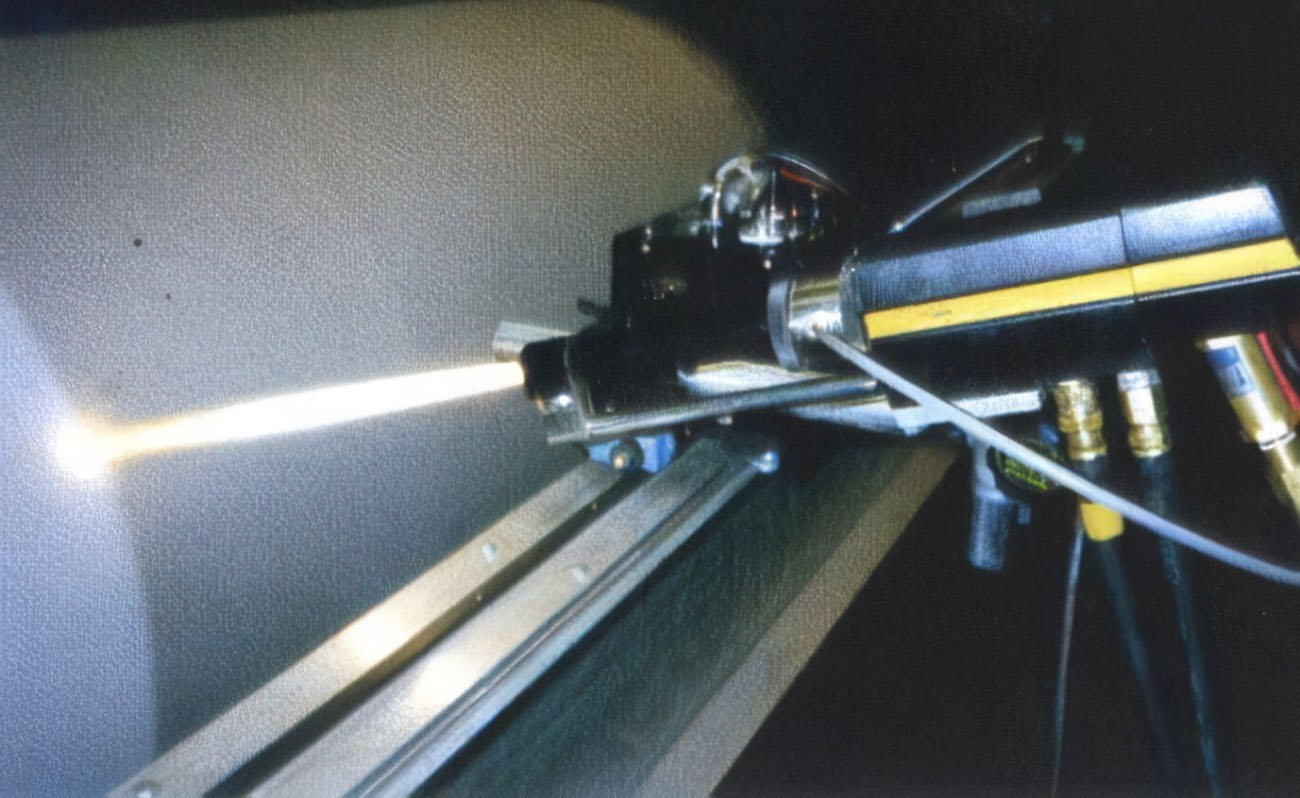

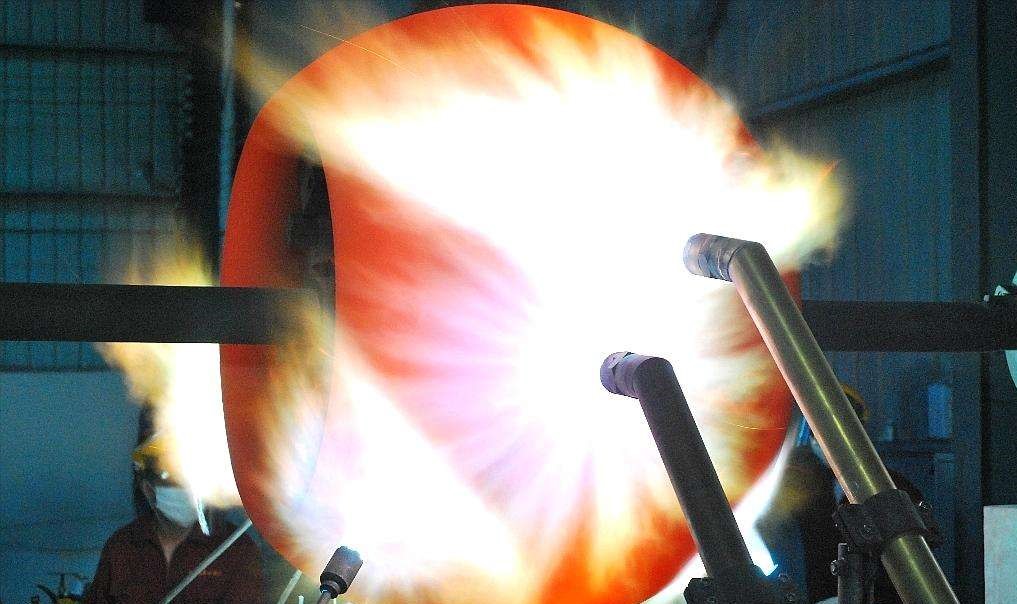

Thermal barrier coating (TBC) bottom layer: such as aircraft engine blades, combustion chambers, etc., first spray nickel-chromium alloy, and then spray zirconium oxide (YSZ) ceramic layer.

Wear-resistant ceramic coating transition layer: such as Al2O3, Cr2O3 ceramic primer before spraying, used for chemical pumps, valves, etc.

High-temperature oxidation resistance pretreatment: high-temperature furnace rollers, heat treatment equipment before spraying ceramic base strengthening.

Process points

Before spraying, the substrate needs to be sandblasted and roughened (Ra 3.5-5.0μm) to improve the bonding strength.

The thickness of the primer is usually controlled at 50-150μm. Too thick may cause failure due to stress.

This type of primer can significantly improve the service life of ceramic coatings and is a key transition material for high-temperature, wear-resistant or insulating coating systems.