Plasma Cladding Technology: Principles and Applications

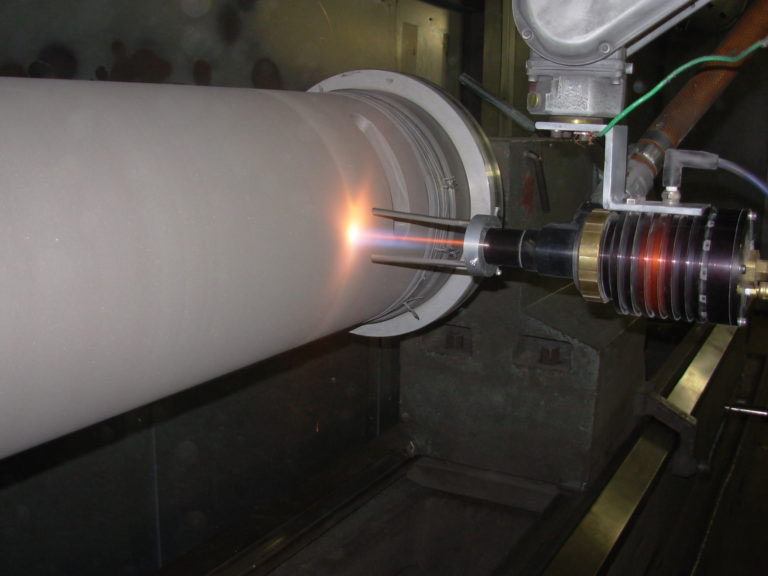

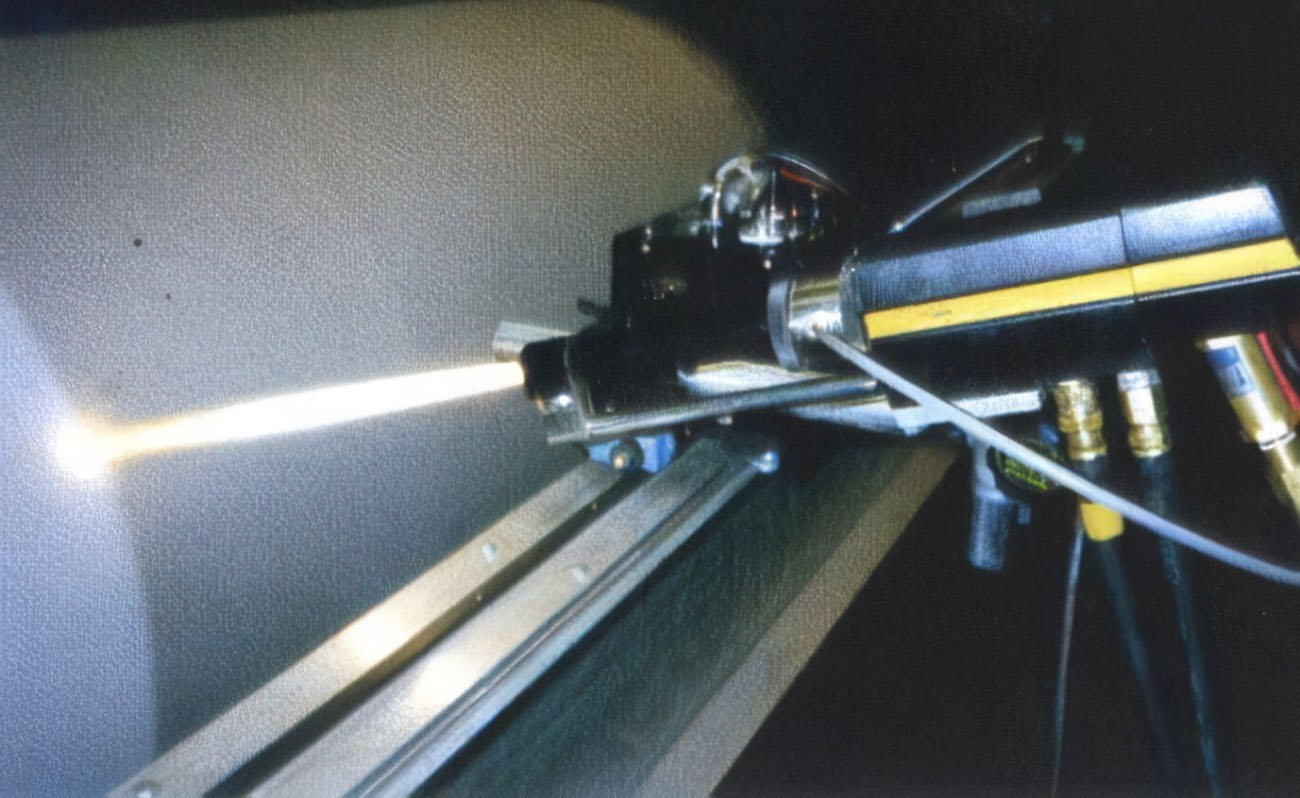

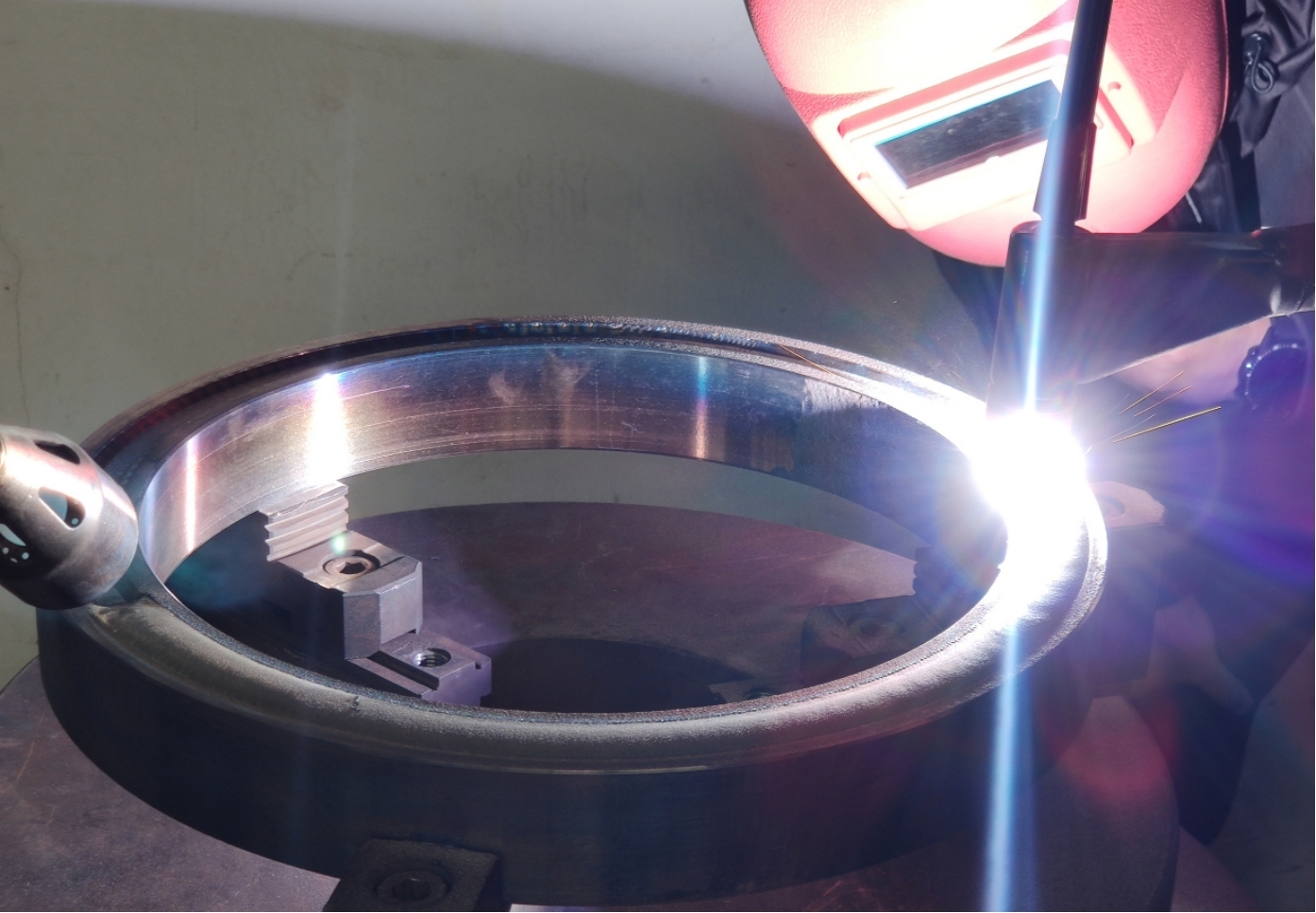

Plasma cladding technology began to be applied in industrial settings in the 1960s. It utilizes the tungsten electrode of a welding torch as the negative electrode and the substrate as the positive electrode, generating plasma between them to produce heat. This heat is transferred to the surface of the workpiece being welded, while welding powder is introduced into the heated area, melting it and depositing it onto the surface of the workpiece. This process achieves the reinforcement and hardening of the part's surface. Plasma cladding technology boasts several advantages, including high productivity, aesthetically pleasing formations, and the ease of mechanization and automation during the cladding process.

Compared to tungsten electrode arc welding, plasma cladding offers stronger control over penetration depth, higher deposition rates, and greater productivity. The interface between the substrate material and the cladding material exhibits a metallurgical bond, resulting in high bonding strength, low heat input, and minimal dilution. Importantly, because the tungsten electrode in plasma cladding carries a lower current than in argon arc welding, it is less likely to melt and evaporate, which can introduce contaminants into the molten pool.

While plasma cladding may be slightly less flexible and convenient than manual arc welding, it demonstrates significant advantages in production efficiency. Manual arc welding often involves high labor intensity, which can adversely affect the health of welders, and the quality of the products is heavily influenced by the skill level of the welder and the quality of the welding rods. In contrast, plasma cladding offers greater flexibility in welding positions compared to submerged arc welding. Additionally, the plasma arc itself has advantages such as concentrated arc heat, stable arc characteristics, and low dilution rates.

With the advancement of automatic control technology, more and more cladding equipment is incorporating CNC control, allowing for precise control of important cladding parameters such as arc pressure, current, powder feed rate, oscillation amplitude, and oscillation frequency. Furthermore, the introduction of numerical control systems in cladding setups enables the control of welding torch travel speed and workpiece movement. By adjusting relevant cladding parameters, the thickness, width, and hardness of the cladding layer can be freely adjusted within certain limits.

Compared to other cladding technologies, plasma cladding results in minimal mutual melting between the substrate material and the cladding material, leading to minimal changes in the properties of the cladding material. Additionally, using powder as the cladding material enhances the freedom of alloy design, making it possible to use difficult-to-clad materials, significantly improving the wear resistance, high-temperature resistance, and corrosion resistance of the workpiece. Therefore, plasma cladding can be widely used in the manufacturing of new products and the remanufacturing of equipment in industries such as petroleum, chemical engineering, construction machinery, and mining machinery.

1. Principles of Plasma Cladding Technology

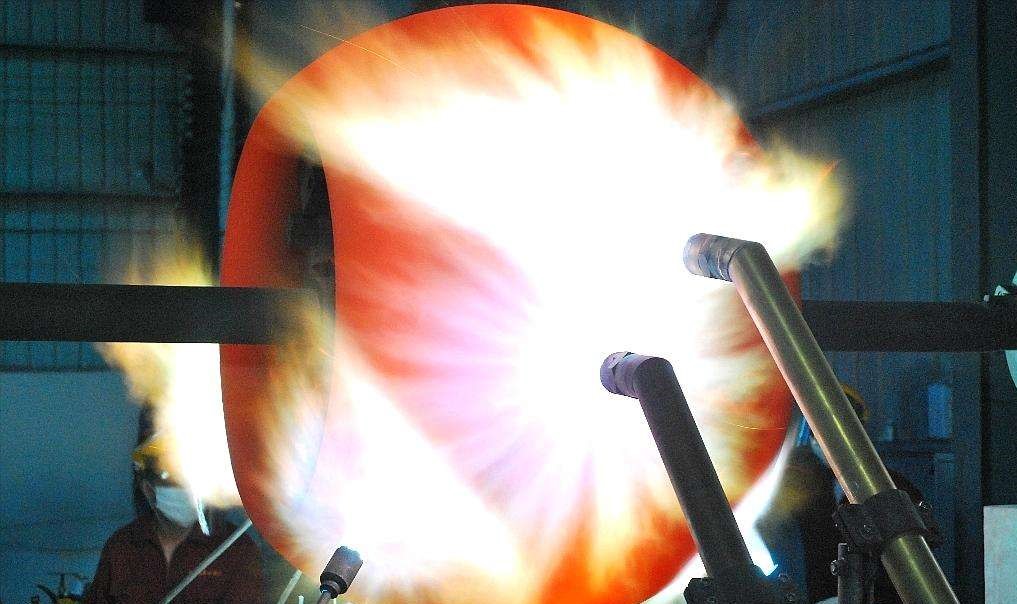

Plasma powder cladding uses a plasma arc as the heat source. The high temperature generated by the plasma arc rapidly heats the alloy powder and the surface of the substrate, causing them to melt, mix, diffuse, and solidify together. After the plasma beam leaves, self-induced cooling occurs, forming a high-performance alloy layer. This process achieves the reinforcement and hardening of the part's surface. Due to the high temperature of the plasma arc, high heat transfer rate, and good stability, the penetration depth can be controlled effectively. By adjusting relevant cladding parameters, the thickness, width, and hardness of the cladding layer can be freely adjusted within certain limits.

After plasma powder cladding, a fusion interface is formed between the substrate material and the cladding material, resulting in high bonding strength. The microstructure of the cladding layer is dense, exhibiting good corrosion and wear resistance. The dilution of the substrate material with the cladding material is minimized, leading to minimal changes in material properties. Utilizing powder as the cladding material allows for greater selectivity in alloy design, particularly enabling the successful cladding of difficult-to-weld materials, thereby enhancing the wear resistance, high-temperature resistance, and corrosion resistance of the workpiece.

Plasma powder cladding is characterized by high productivity, aesthetically pleasing formations, and ease of mechanization and automation during the cladding process. The plasma arc is a high-temperature, high-energy beam, with arc temperatures reaching up to 30,000°C and power densities ranging from 1.5 × 10² to 1.6 × 10⁴ W/mm². The highly compressed plasma arc used for welding, cutting, and spraying can achieve effects comparable to laser and electron beam methods. In contrast, the lower-compression plasma arc used for cladding is a flexible arc with adjustable compression, capable of meeting the demands for high-speed deposition while maintaining low dilution rates and minimizing the occurrence of double arcs, making it an ideal heat source for cladding.

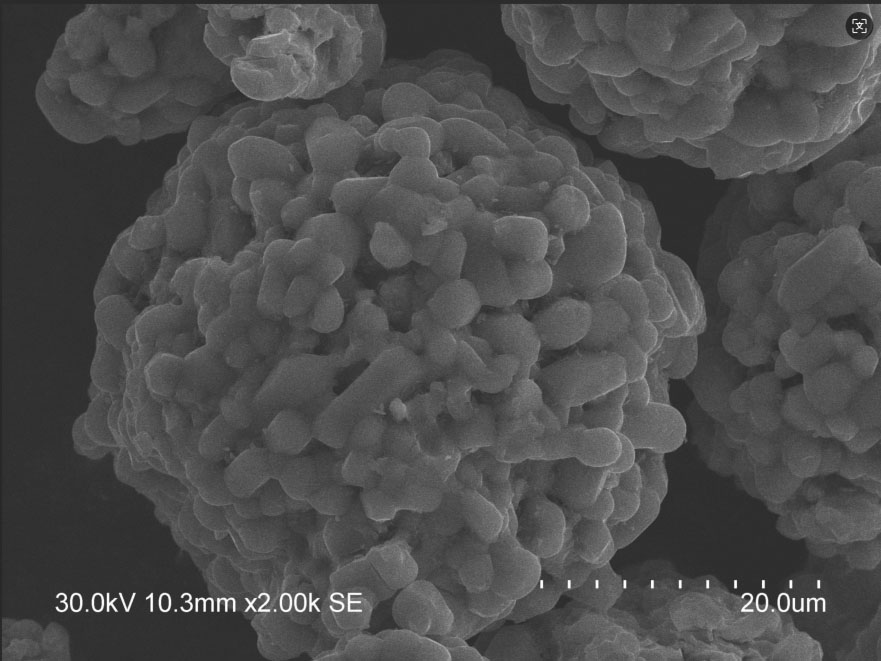

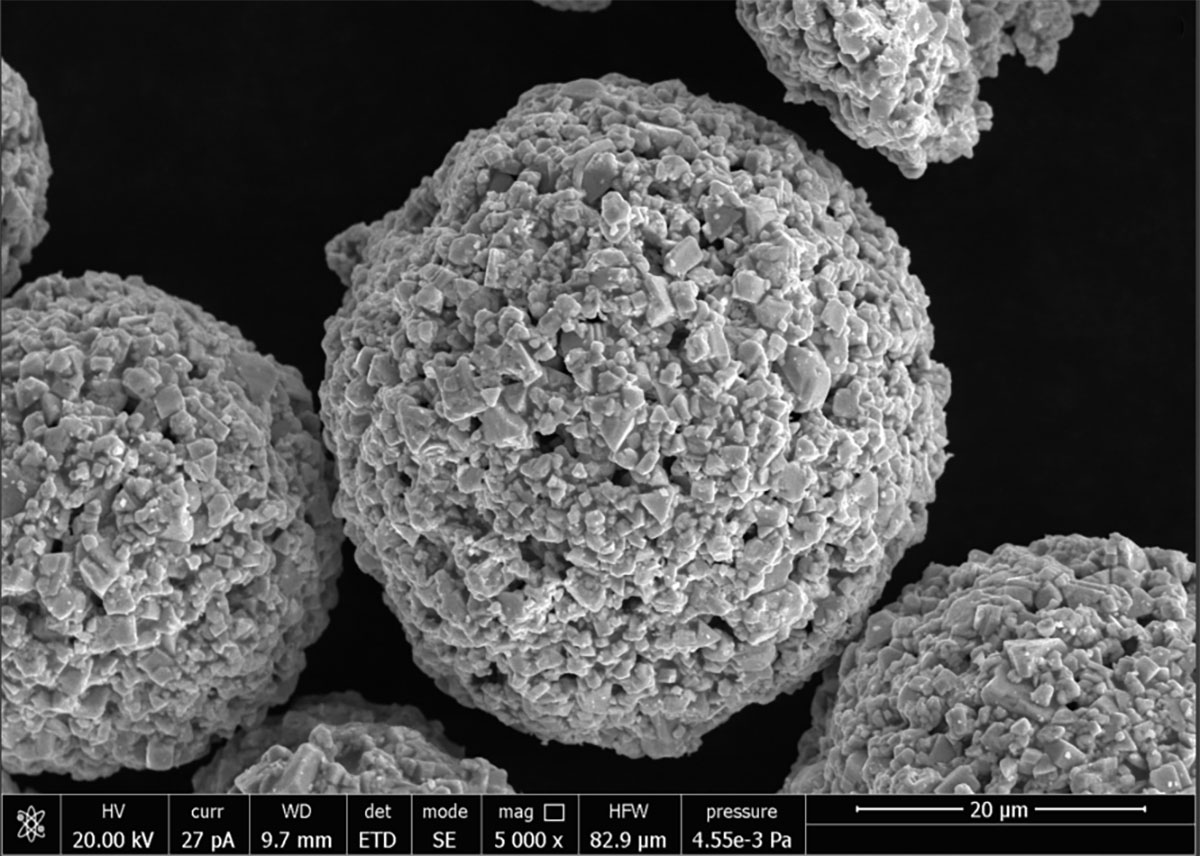

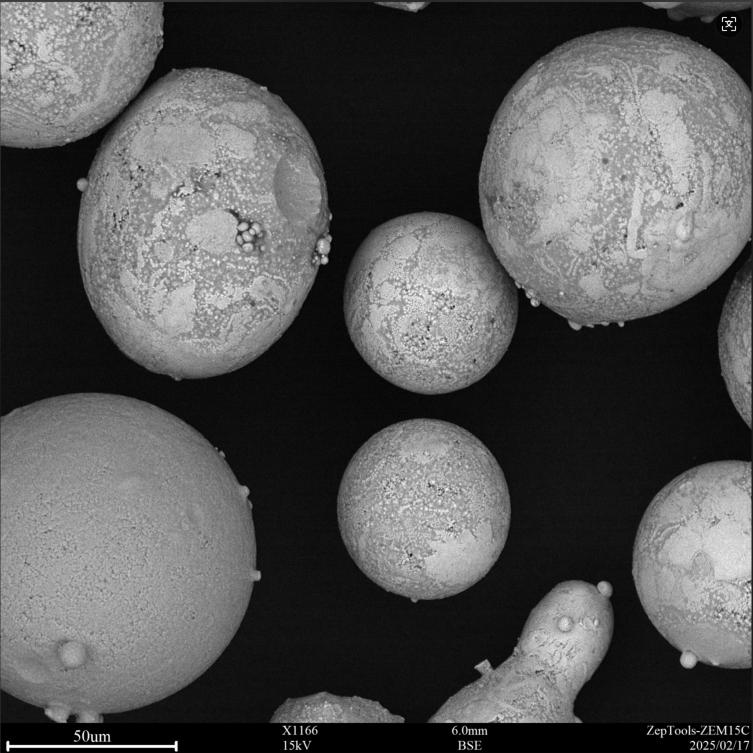

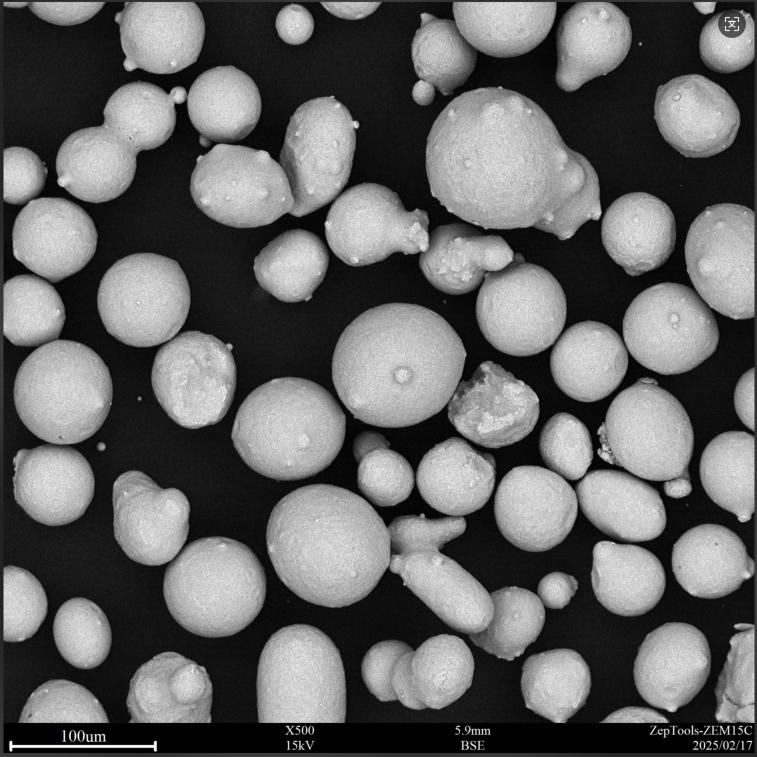

The primary form of plasma cladding material is powder. The chemical composition of the powder can be flexibly varied, making it easier to adjust the composition and performance of the cladding layer compared to other cladding methods that use wire. The most commonly used powder material in plasma cladding is self-fusing alloy powder. This type of alloy powder possesses self-fluxing properties, eliminating the need for additional flux during cladding. The alloy itself provides deoxidation, slag formation, and improved wettability.

During use, two or more different types of powders (one of which can be a hard phase) can be mechanically mixed in specific proportions to obtain a cladding alloy powder with different compositions and properties. This method is often employed in experiments to quickly achieve a desired alloy performance. The dilution rate of the cladding layer is one of the primary indicators reflecting the characteristics of a cladding method. The dilution rate directly affects the final composition and metallographic structure of the cladding layer, ultimately determining the performance of the surface cladding layer.

By leveraging the controllability of the plasma cladding heat source, when using self-fusing alloy powders, the dilution rate of the substrate metal to the cladding layer can be kept within a low range, such as 3-7%. If using a reverse polarity plasma cladding method, even lower dilution rates can be achieved. However, excessively low dilution rates, such as below 3%, can make it difficult to ensure a uniform fusion interface across conventional components and may carry the risk of incomplete fusion defects.

The deposition efficiency of plasma powder cladding refers to the percentage of the deposited metal relative to the mass of the powder material used during the cladding process. It reflects the utilization rate of the cladding material. The size of the deposition efficiency directly relates to the production cost of plasma cladding, especially when using high-cost powder alloys. The deposition efficiency of plasma cladding generally ranges from 80% to 95%, and under certain conditions, it can exceed 95%. The deposition speed refers to the mass of effective cladding alloy deposited per unit time, with recent data indicating that the deposition speed of plasma powder cladding can reach 12.5 kg/h or higher.

2. Applications of Plasma Cladding Technology

Plasma cladding technology finds applications across various industries due to its unique advantages. Here are some key areas of application:

1. Construction Machinery: Plasma cladding is used to enhance the wear resistance of components such as bricks, tiles, mixing blades, and hammers. It is also applied to parts like cement plant components, including tower trays, liners, and crushing machines.

2. Mining Machinery: In the mining industry, plasma cladding is employed to improve the durability of equipment subjected to harsh conditions, such as excavators, shovels, and crushing equipment. The enhanced wear resistance and corrosion resistance of cladded components lead to longer service life and reduced maintenance costs.

3. Oil and Chemical Industries: Plasma cladding is utilized to protect equipment from corrosion and wear in oil and chemical processing environments. Components such as pipelines, valves, and pumps benefit from the enhanced properties provided by plasma cladding, ensuring reliable operation in challenging conditions.

4. Aerospace and Defense: In aerospace applications, plasma cladding is used to improve the performance of critical components exposed to extreme temperatures and corrosive environments. The technology is also applied in defense applications, where enhanced material properties are essential for the reliability and longevity of equipment.

5. Tool Manufacturing: Plasma cladding is employed to enhance the performance of cutting tools and dies. The improved hardness and wear resistance of cladded tools lead to increased productivity and reduced tool wear, resulting in cost savings for manufacturers.

6. Remanufacturing: Plasma cladding technology is widely used in the remanufacturing of worn-out components. By applying a cladding layer, the original dimensions and properties of the components can be restored, extending their service life and reducing waste.

7. Research and Development: Plasma cladding is also utilized in research and development settings to explore new materials and coatings. The ability to adjust the composition and properties of the cladding layer allows researchers to investigate innovative solutions for various applications.

Conclusion

Plasma cladding technology represents a significant advancement in surface treatment methods, offering a range of benefits including high productivity, excellent material properties, and the potential for automation. Its versatility allows for applications across various industries, from construction and mining to aerospace and tool manufacturing. As technology continues to evolve, plasma cladding is expected to play an increasingly important role in enhancing the performance and longevity of components in demanding environments. The ability to precisely control cladding parameters and utilize a wide variety of materials positions plasma cladding as a valuable solution for modern manufacturing and remanufacturing challenges.