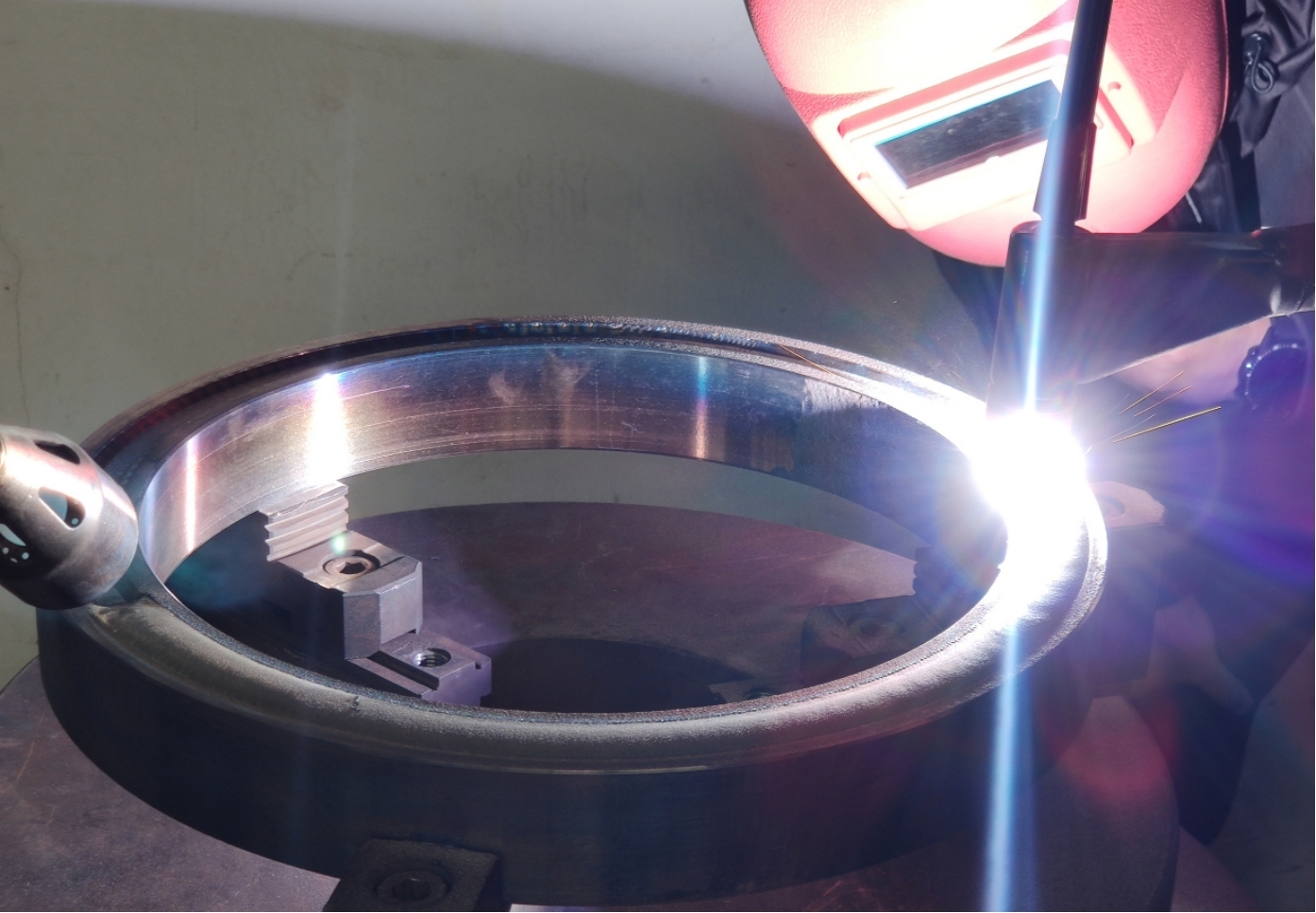

Oxyacetylene flame spray welding (welding) method

- Pretreatment

Clean the substrate: remove oil and rust (acetone or sandblasting)

Preheating: 200-300℃ (to prevent thermal stress cracking, especially for high carbon steel or cast iron)

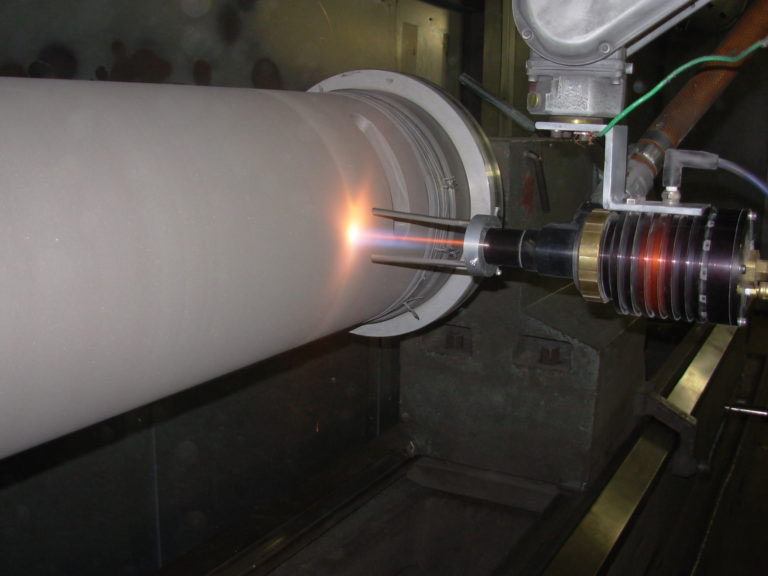

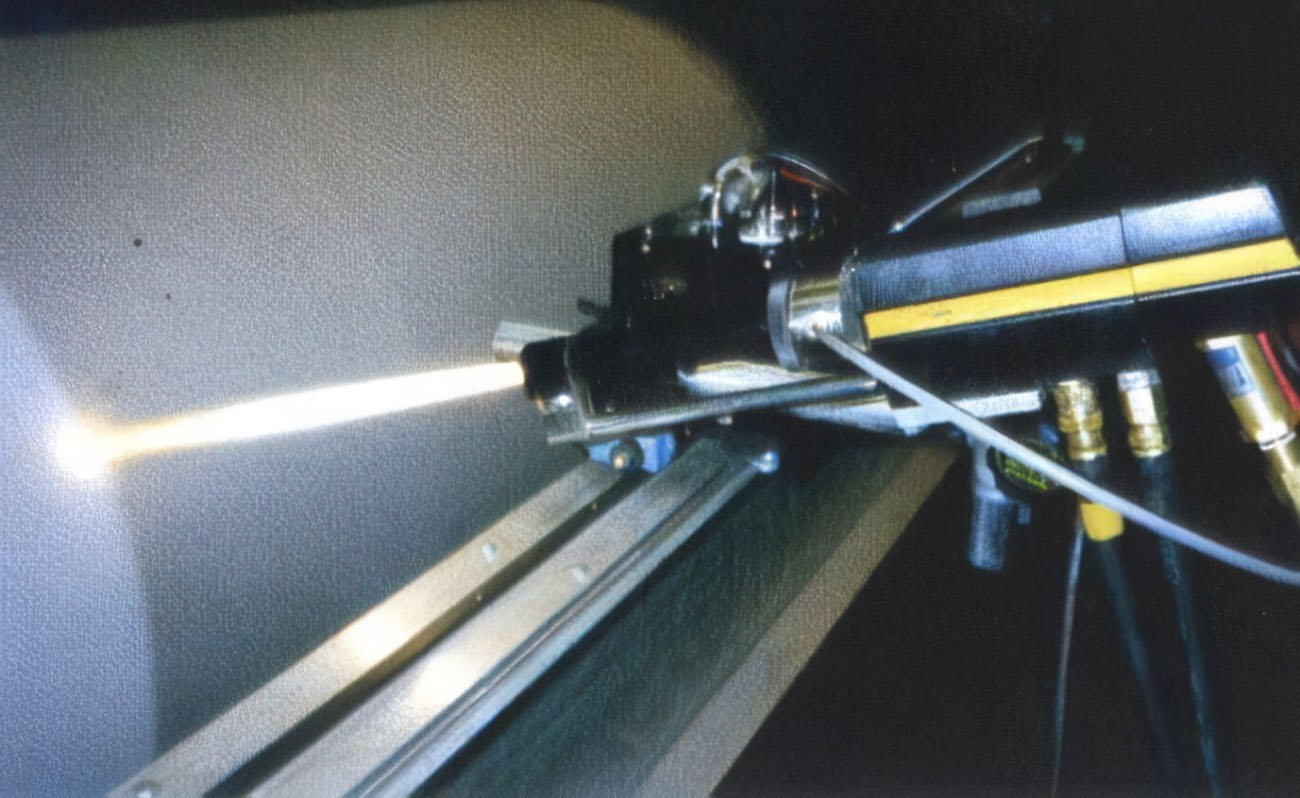

- Spray welding process

Flame adjustment: neutral flame (oxygen acetylene ratio 1:1), avoid oxidation or carburization

Powder feeding method:

One-step method: melting and feeding powder (powder is directly sprayed to the substrate through a flame spray gun)

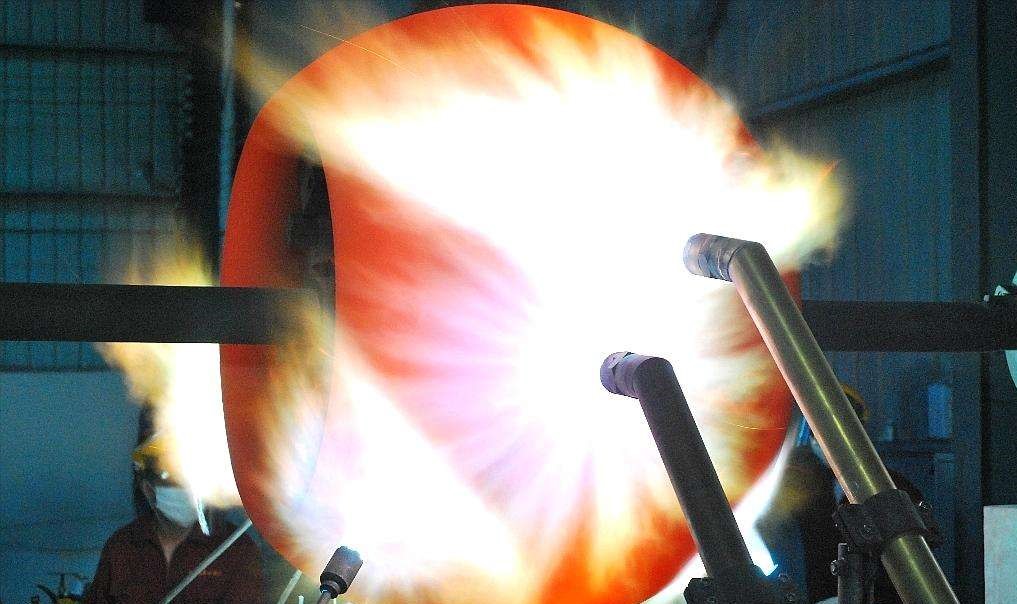

Two-step method: first spray alloy powder, then remelt with flame (suitable for complex shapes or thick coatings)

Operation parameters:

Spray distance: 150-200mm (one-step method); flame distance 20-50mm during remelting

Angle: 75-90° between the spray gun and the substrate

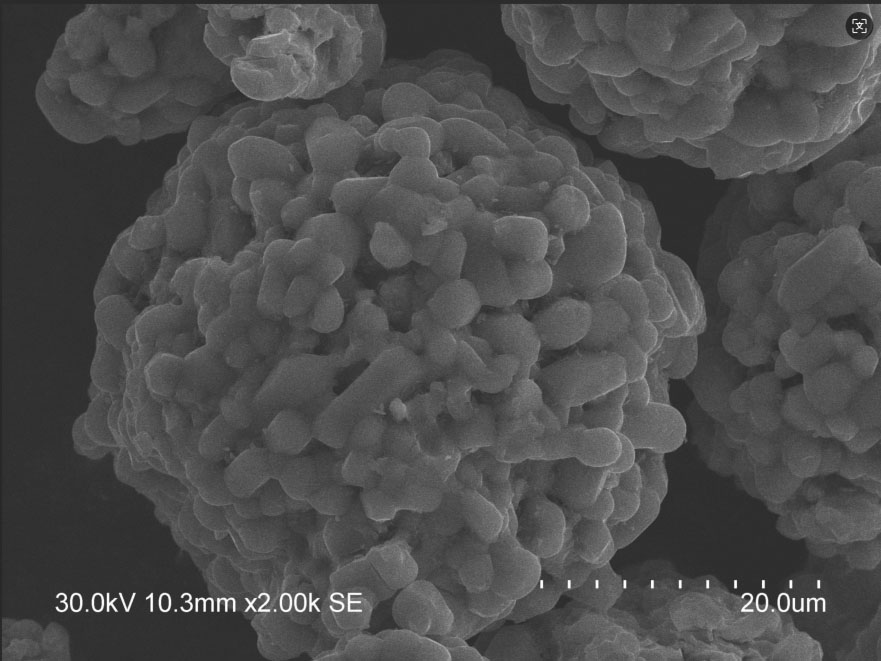

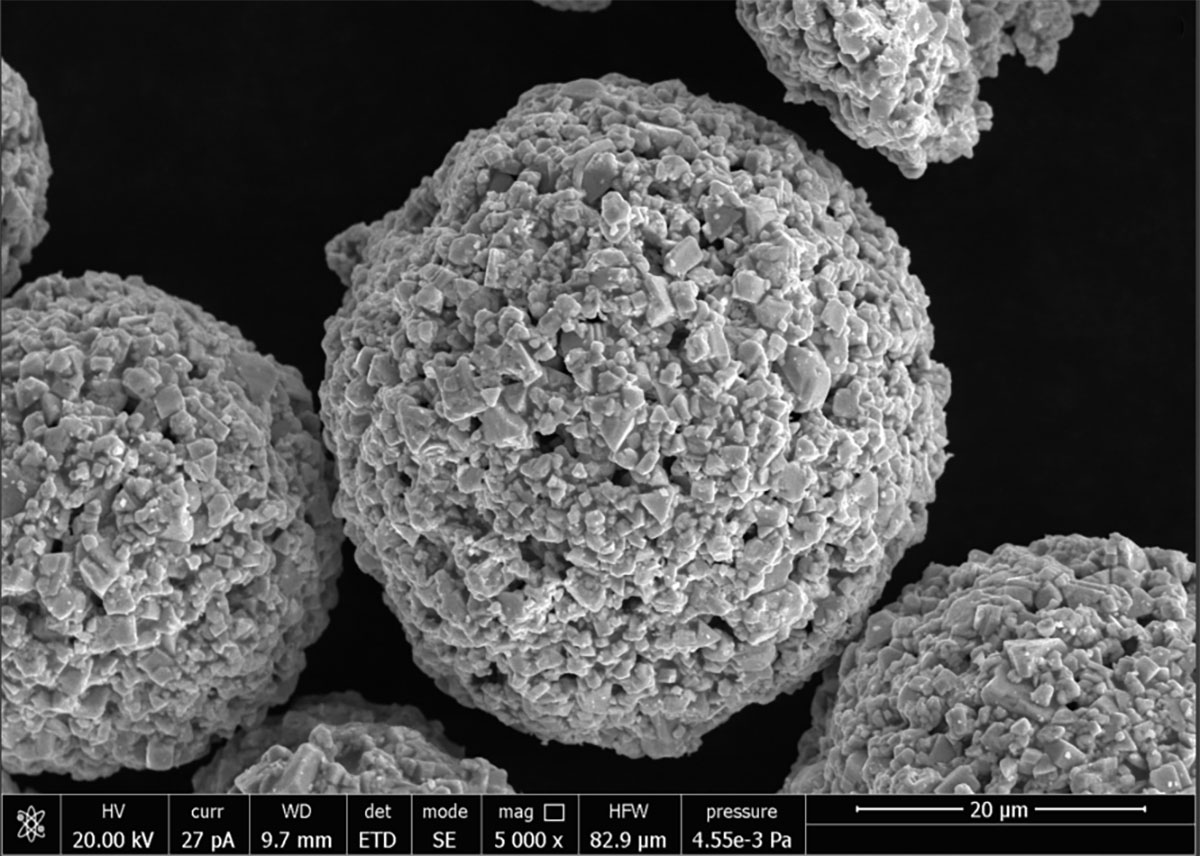

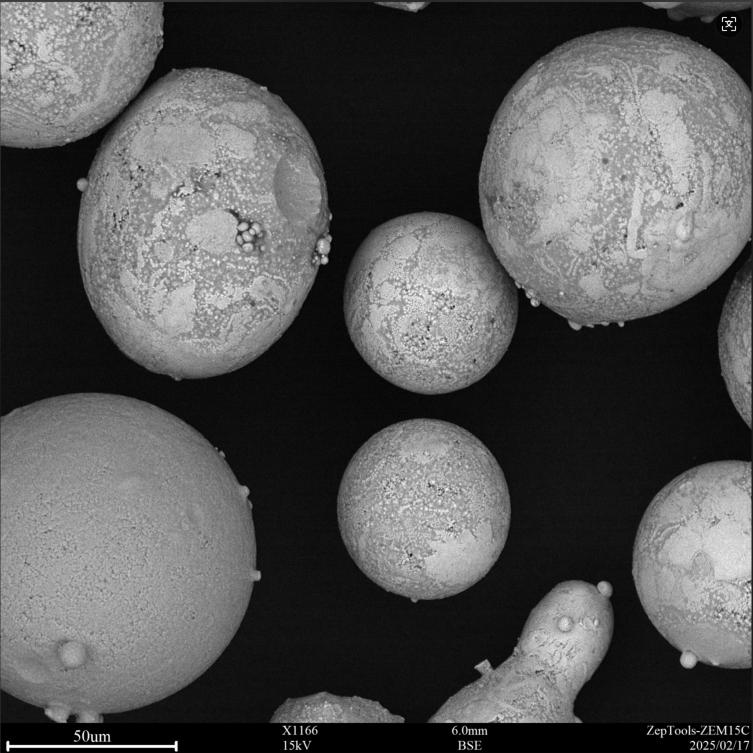

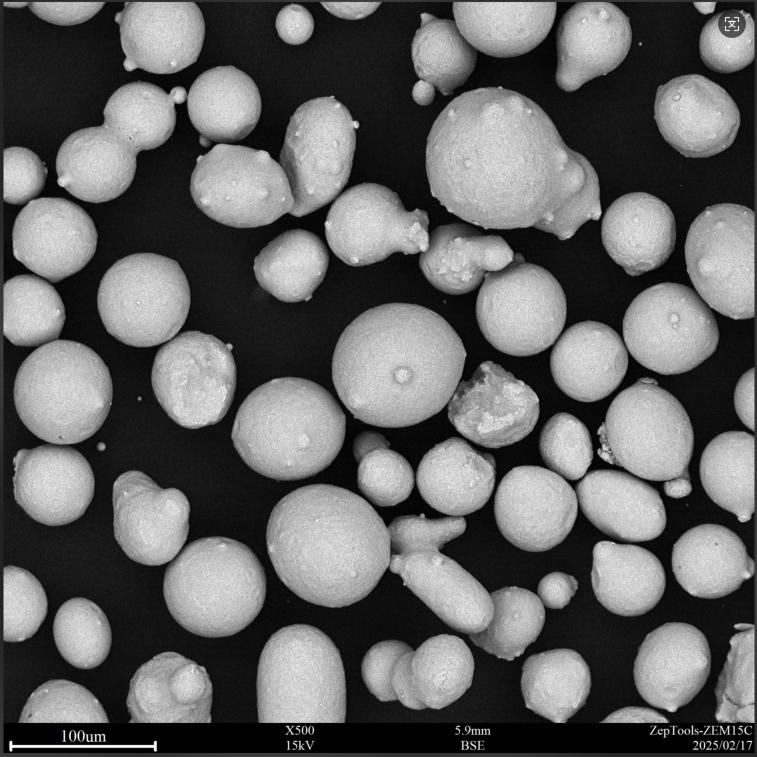

Powder particle size: usually 150-325 mesh (45-100μm)

- Post-treatment

Slow cooling: asbestos felt wrapping or furnace cooling (to prevent cracks, especially for cast iron parts)

Machining: grinding or turning to the required size (Ni60 has high hardness and requires carbide tools)

Precautions

Thickness control: single layer spray welding ≤ 2mm, too thick is prone to pores or peeling

Substrate restrictions: suitable for steel, cast iron, nickel-based alloys, not recommended for direct use in copper and aluminum (requires nickel transition layer)

Deformation prevention: symmetrical heating or segmented construction to reduce local overheating

Ni60 oxyacetylene spray welding layer has high bonding strength (≥300MPa), suitable for on-site maintenance or occasions where plasma/laser processes cannot be used, but skilled operation is required to avoid overburning or unmelted defects.