Characteristics of Supersonic Sprayed Tungsten Carbide

Supersonic flame spraying is an advanced thermal spraying technology that has gained significant attention in the field of materials surface treatment. This technique is particularly effective for creating coatings that require high wear resistance and corrosion resistance. Tungsten carbide (WC) is a key spraying material known for its exceptional physical and chemical properties. In this article, we will explore the characteristics of supersonic sprayed tungsten carbide and its various applications.

1. Working Principle of Supersonic Spraying

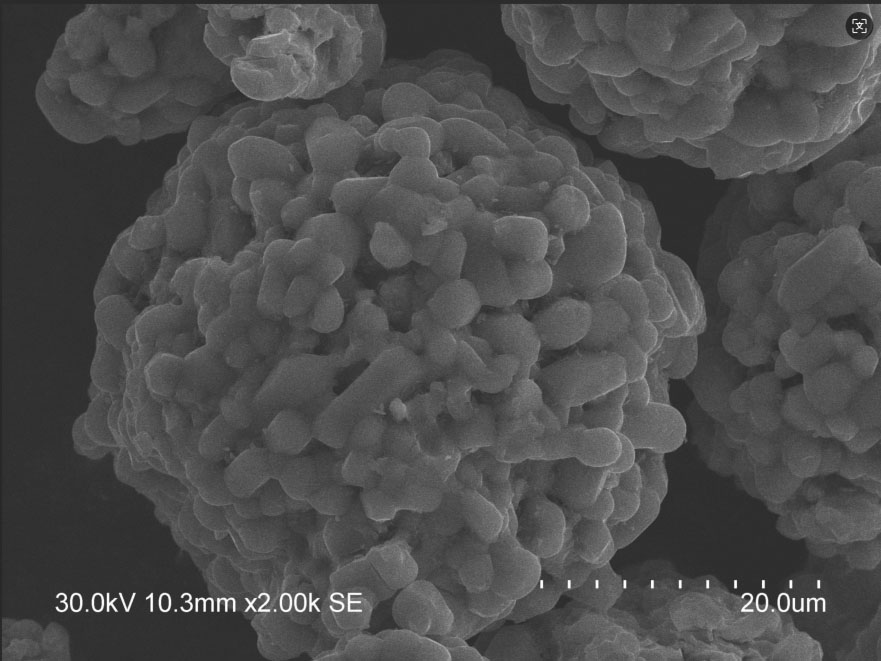

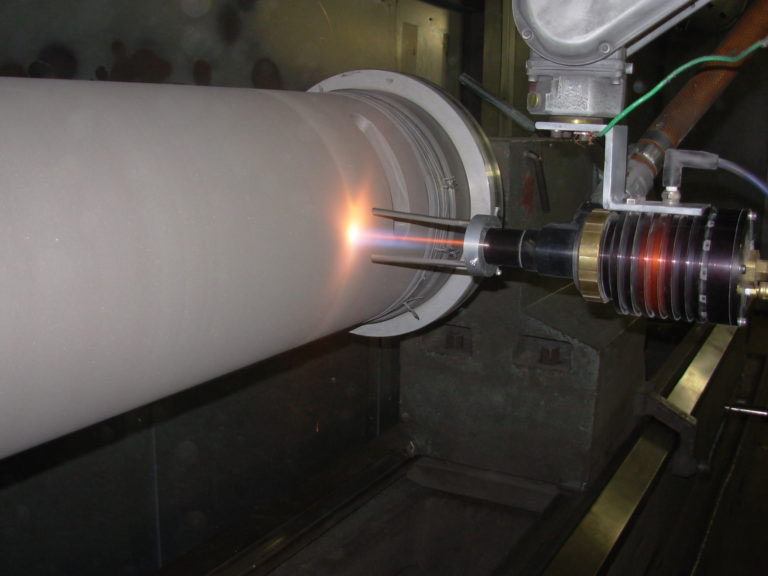

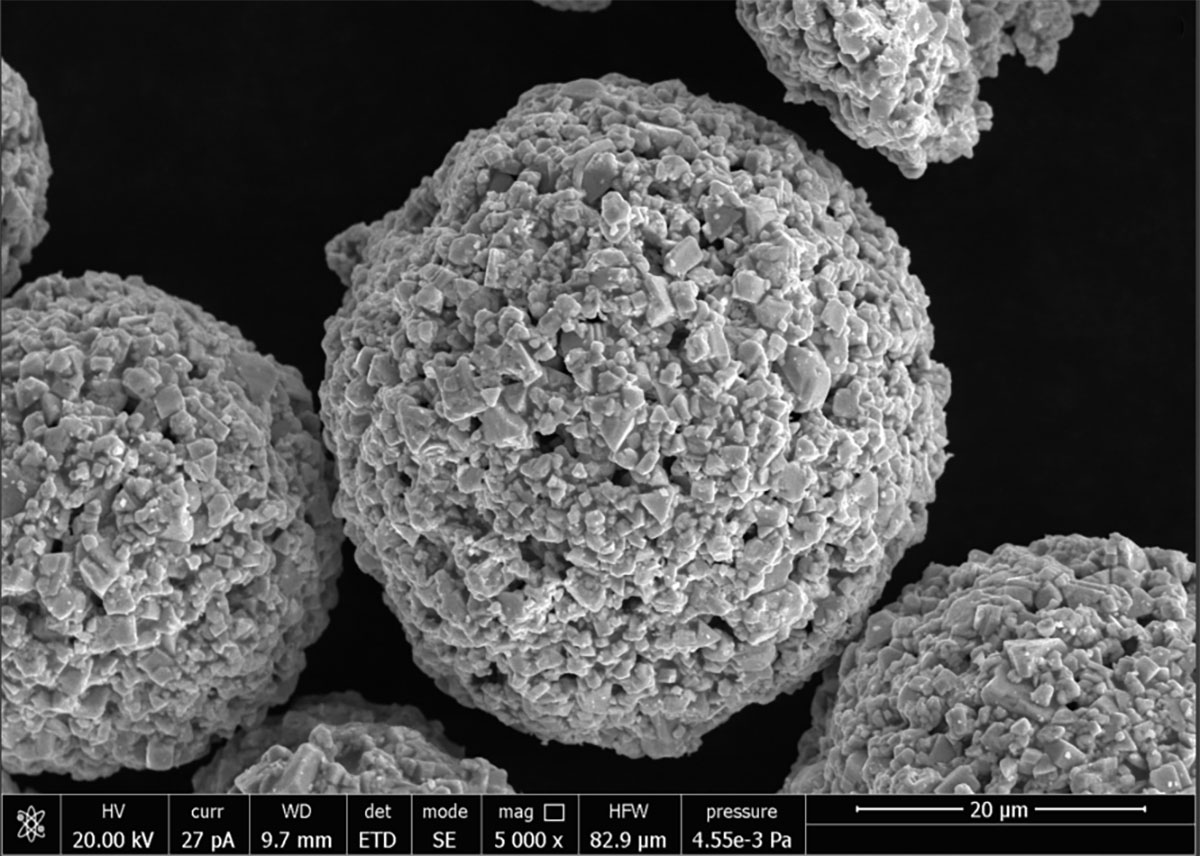

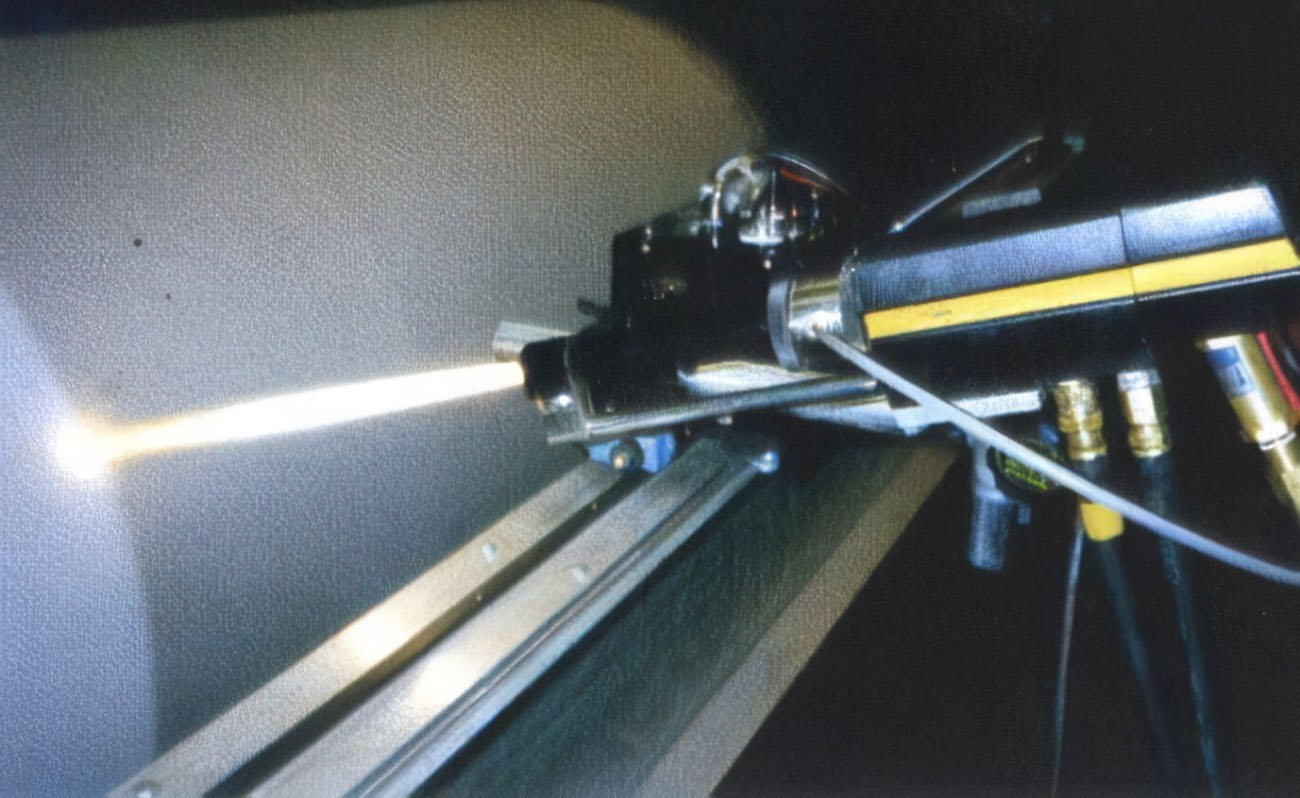

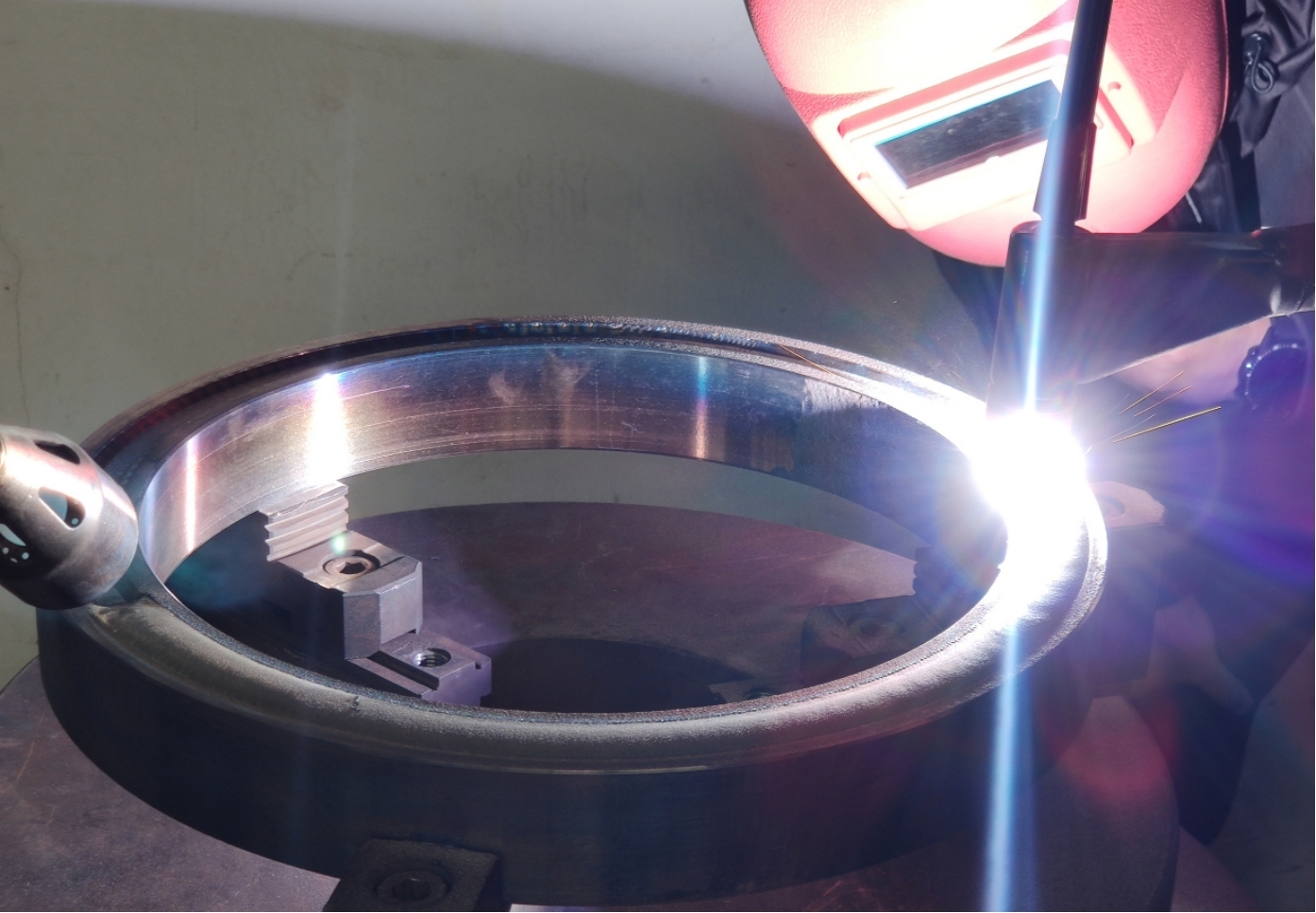

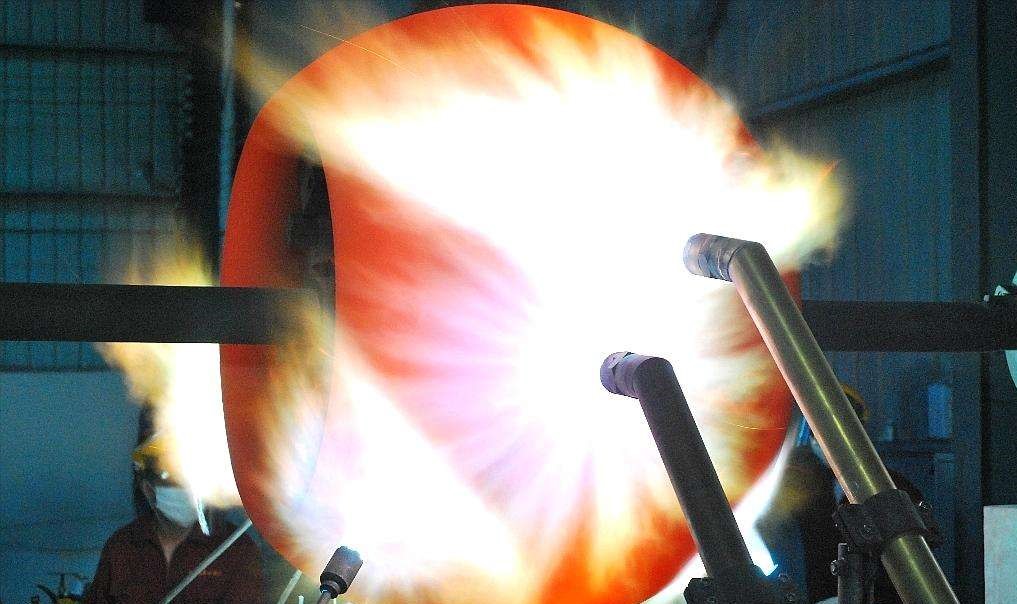

The fundamental principle of supersonic spraying involves the combustion of liquid fuels, such as kerosene, propane, or propylene, mixed with oxygen. This mixture is atomized and ignited, resulting in a vigorous gas-phase reaction. The combustion process releases thermal energy, causing the gas to expand rapidly and form a high-temperature, high-pressure gas flow. As this gas passes through a Laval nozzle, it is constricted, allowing the gas to reach supersonic speeds. The sprayed powder is heated to a molten or semi-molten state and accelerated to speeds of up to 300-500 meters per second, or even higher, before being directed toward the substrate surface to form a high-quality coating.

2. Characteristics of Supersonic Sprayed Tungsten Carbide

Supersonic sprayed tungsten carbide possesses several notable characteristics that make it a preferred choice for various applications:

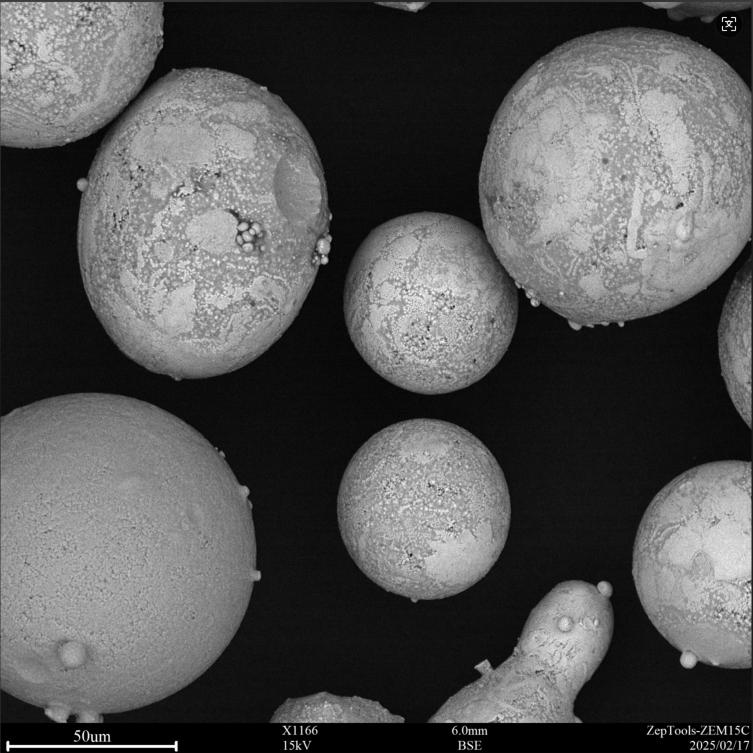

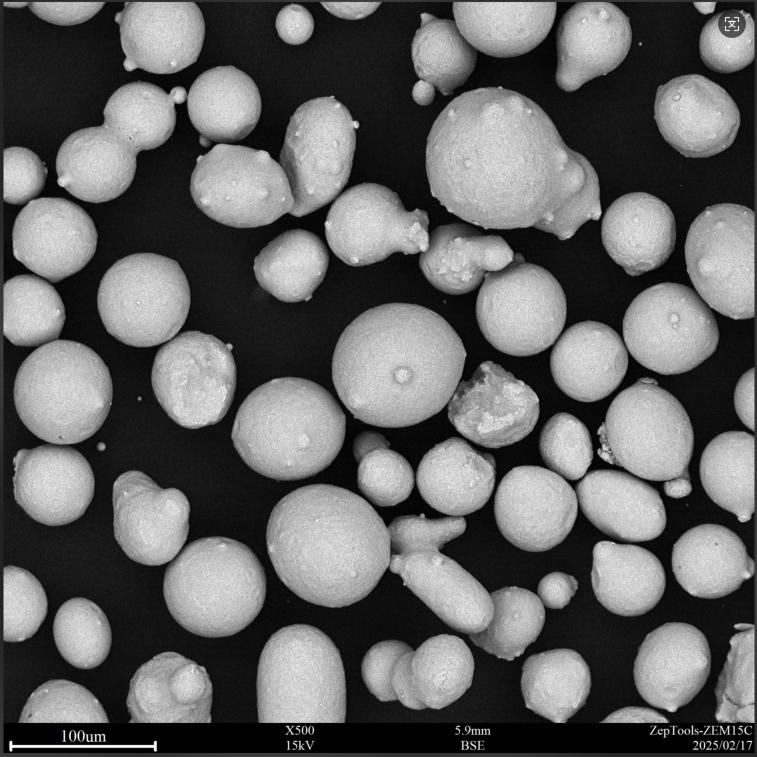

1. High Spraying Speed: The flame speed in supersonic spraying is typically five times the speed of sound, with the spraying powder speed reaching up to 2000 meters per second. This high velocity significantly enhances the density and bonding strength of the coating, resulting in a porosity of less than 1% and a bonding strength greater than 70 MPa.

2. High Coating Density and Bonding Strength: The combination of high speed and temperature during the spraying process leads to coatings with high density and bonding strength. This allows the coatings to withstand greater mechanical stress and wear during use, making them suitable for demanding applications.

3. Low Oxidation Degree: The oxidation degree of the coating material during the supersonic spraying process is relatively low, which helps maintain the reactivity of the material. This is crucial for enhancing the coating's corrosion resistance and wear resistance.

4. Excellent Wear and Corrosion Resistance: Tungsten carbide is a compound with a hardness close to that of diamond, providing outstanding wear resistance. The coatings can effectively resist abrasive wear and corrosive wear, making them ideal for various harsh environments.

5. High-Temperature Oxidation Resistance: Tungsten carbide coatings, produced through high-temperature calcination, can resist high-temperature oxidation and aging. They are less prone to wear even under prolonged exposure to steam corrosion, making them highly applicable in high-temperature environments.

6. Good Electrical Conductivity and Resistance: The raw materials used for tungsten carbide coatings possess electrical conductivity, making them suitable for applications requiring conductive properties. This opens up significant potential for use in electronic and electrical devices.

7. Chemical Stability: Tungsten carbide is insoluble in water, hydrochloric acid, and sulfuric acid, exhibiting excellent chemical stability. This makes it particularly advantageous for preparing corrosion-resistant coatings.

8. Enhanced Reliability: During the preparation of tungsten carbide coatings, the high-speed impact and intense deformation cause distortion in the material's lattice structure. This increases the material's reactivity and enhances the likelihood of physical bonding with adjacent particles or the substrate material, resulting in higher coating reliability.

3. Application Areas of Supersonic Sprayed Tungsten Carbide

The exceptional properties of supersonic sprayed tungsten carbide have led to its widespread application across various industries:

Aerospace: In the aerospace sector, tungsten carbide coatings can be used for engine components and other parts exposed to high temperatures and pressures, providing excellent wear and corrosion protection. The ability to withstand extreme conditions makes these coatings essential for ensuring the reliability and performance of aerospace systems.

Automotive Industry: In automotive manufacturing, tungsten carbide coatings are applied to engine components, transmission systems, and other critical parts to enhance their wear resistance and service life. The coatings help reduce maintenance costs and improve the overall efficiency of automotive systems.

Oil and Gas: In the oil and gas industry, tungsten carbide coatings are utilized for drilling tools and pipelines, resisting wear and corrosion to ensure the reliability of equipment. The harsh environments encountered in this industry make the durability of coatings crucial for operational success.

Chemical Industry: In chemical production, tungsten carbide coatings are used for reactors, pipelines, and storage tanks, providing corrosion protection and extending the service life of equipment. The coatings help maintain the integrity of equipment in aggressive chemical environments.

Mining: In the mining sector, tungsten carbide coatings are applied to mining machinery and equipment to resist wear and corrosion, improving production efficiency. The ability to withstand abrasive conditions is vital for the longevity of mining equipment.

Pulp and Paper Industry: In the pulp and paper industry, tungsten carbide coatings are used for pulp and paper equipment, providing wear and corrosion protection to ensure smooth production processes. The coatings help maintain the performance of equipment in demanding operational conditions.

4. Conclusion

Supersonic sprayed tungsten carbide is a coating material with outstanding performance characteristics. Its high spraying speed, low oxidation degree, excellent wear resistance, and corrosion resistance make it widely applicable in various industries, including aerospace, automotive, oil and gas, chemical, mining, and pulp and paper.

As technology continues to advance, the application prospects for supersonic sprayed tungsten carbide will become even broader. In the future, as the demand for materials with superior performance increases, supersonic spraying technology will continue to evolve, driving the application of tungsten carbide coatings in even more diverse fields. Whether for wear protection in extreme environments or corrosion protection under high-temperature and high-pressure conditions, supersonic sprayed tungsten carbide will remain a vital choice for materials engineers and manufacturers.

In summary, the unique properties of supersonic sprayed tungsten carbide not only enhance the performance of coated components but also contribute to the overall efficiency and reliability of various industrial processes. As industries seek to improve their operational capabilities, the role of advanced materials like tungsten carbide will only become more significant.