Are you familiar with WC-10Co4Cr?

I. Material Composition and Structure

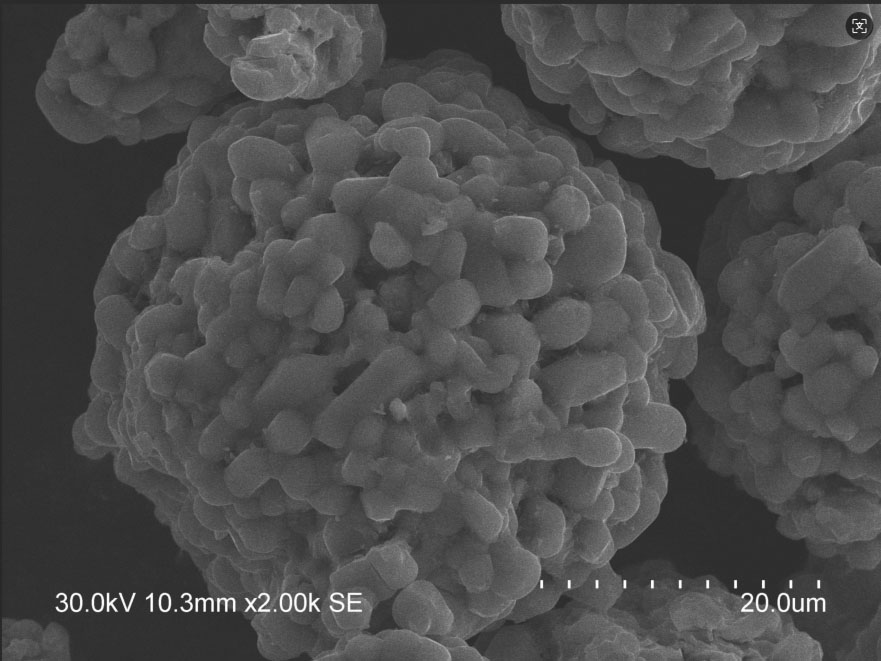

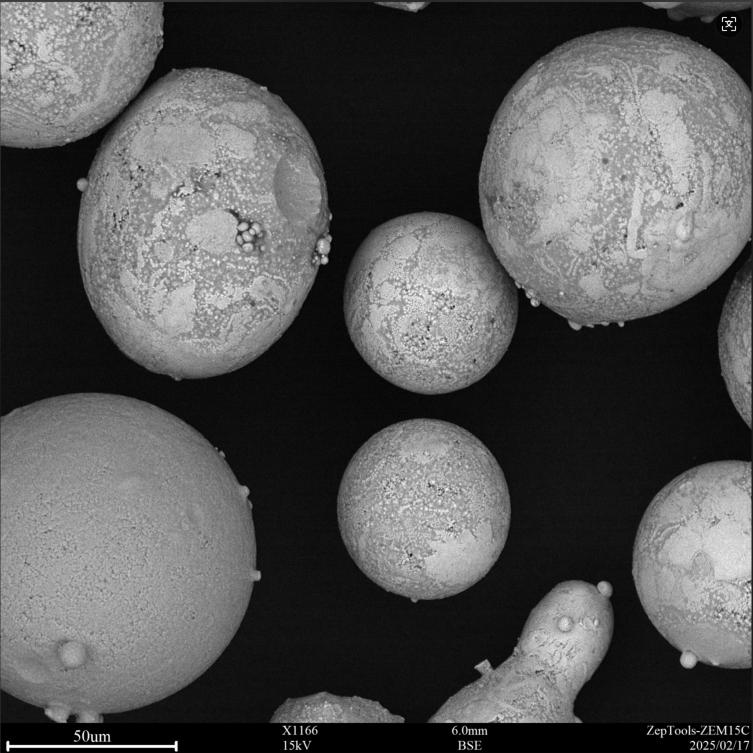

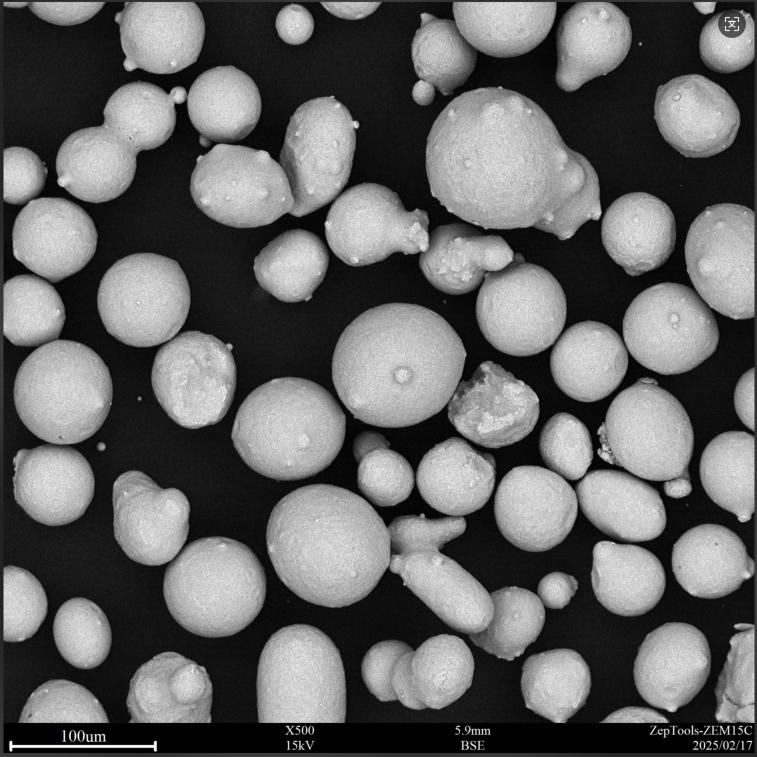

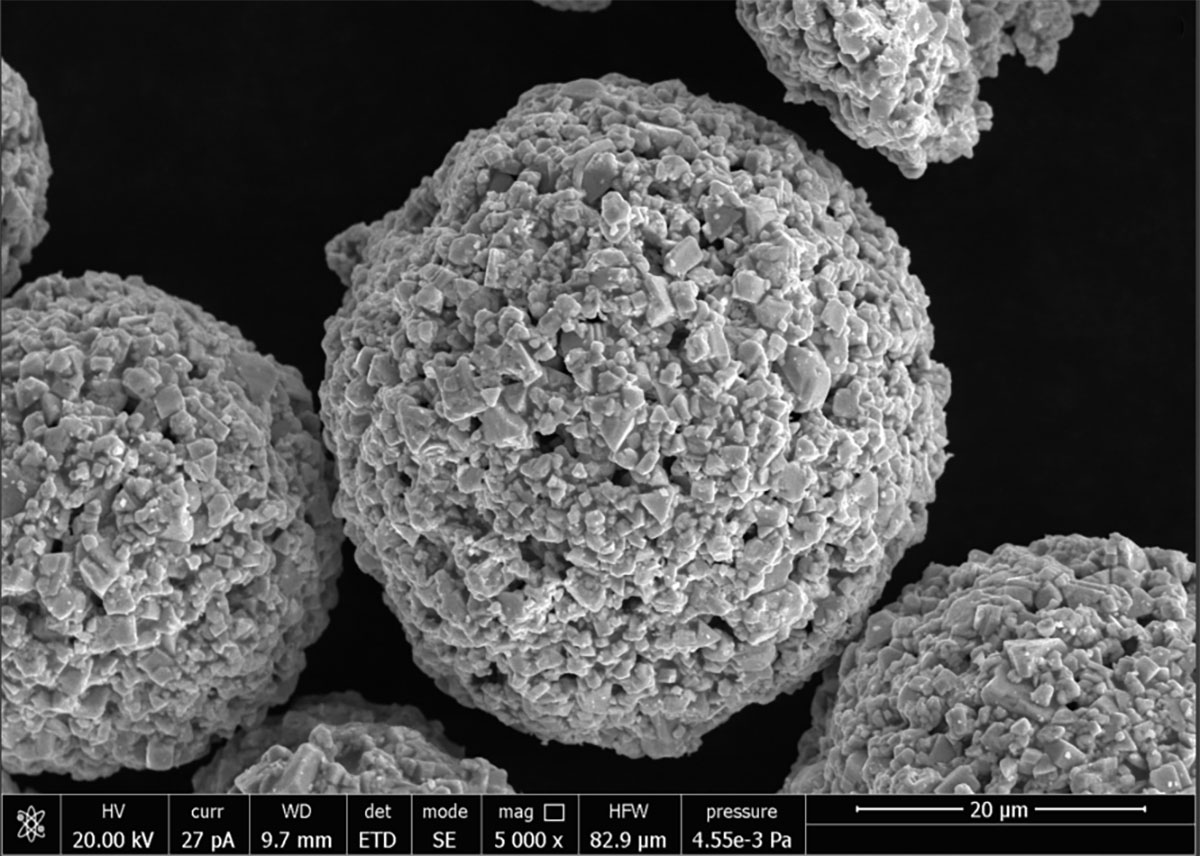

WC-10Co4Cr (86% WC, 10% Co, 4% Cr) is a tungsten carbide-based alloy powder produced through agglomeration and sintering. Its core structure consists of tungsten carbide particles coated with cobalt (Co) and chromium (Cr) metal layers, forming a "core-shell" composite particle structure. This design retains the high hardness of tungsten carbide while enhancing the overall performance of the coating through the bonding properties of cobalt and the corrosion resistance of chromium.

II. Core Performance Characteristics

1. High Hardness and Wear Resistance

- The sprayed coating can achieve a hardness of HV> 1100, significantly higher than that of ordinary steel, effectively resisting abrasive wear, erosive wear, and fretting wear.

- Tests have shown that its wear resistance is over 1.3 times that of traditional alloy coatings, particularly outstanding in sandy water or dusty environments.

2. Optimized Corrosion Resistance

- The addition of chromium (Cr) significantly improves corrosion resistance: In a 3.5% NaCl salt spray environment, the low-porosity coating exhibits superior corrosion resistance to the high-porosity sample; however, protection is limited in strong acid environments (such as HCl).

3. High-Temperature Oxidation Resistance

- The cobalt coating forms a dense oxide film at high temperatures, reducing the decomposition of tungsten carbide and making it suitable for operating conditions below 800°C (e.g., engine components).

III. Industrial Applications

1. Heavy-Duty Wear-Resistant Parts

Oil Drilling: Drill collars, centralizers, and mud pump liners, resisting grit erosion.

Mechanical Manufacturing: Roller journals, hydraulic piston rods, and mold ejectors, extending service life by 3–5 times.

2. Corrosion-Wear Cooperative Environments

Marine and Energy: Seawater pump impellers and turbine blades, offering both seawater corrosion resistance and sand-laden wear resistance.

Chemical Equipment: Valve sealing surfaces and pump flow passage components, suitable for weak acid media.

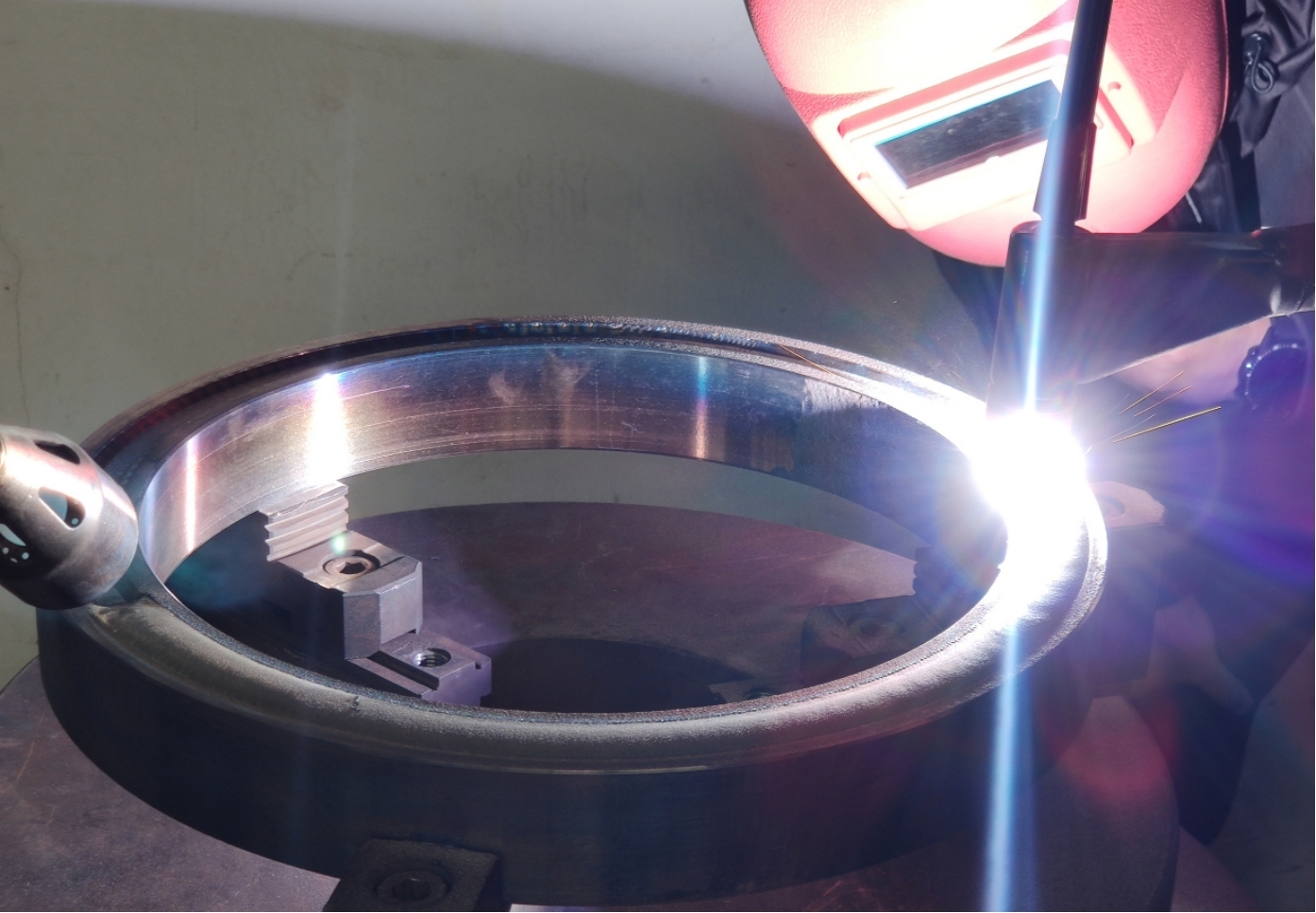

3. High-Precision Surface Enhancement

Aerospace: Compressor blade tenons and landing gear pins, improving resistance to fretting wear.

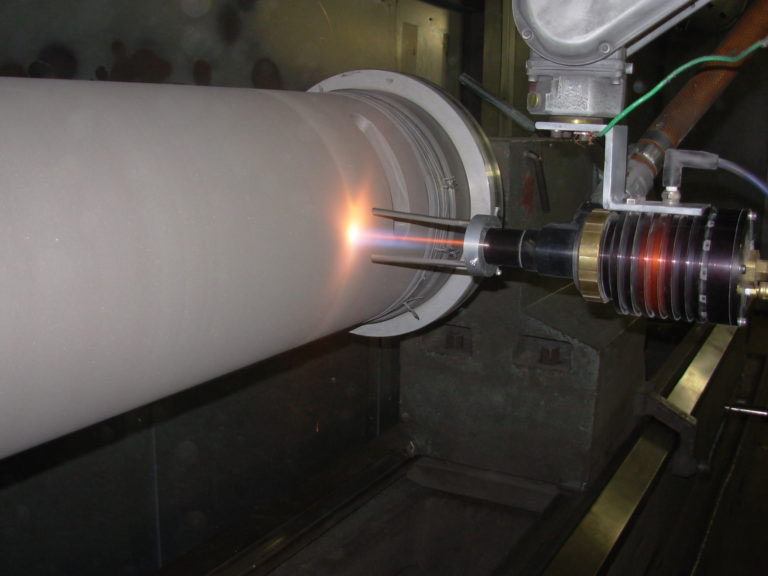

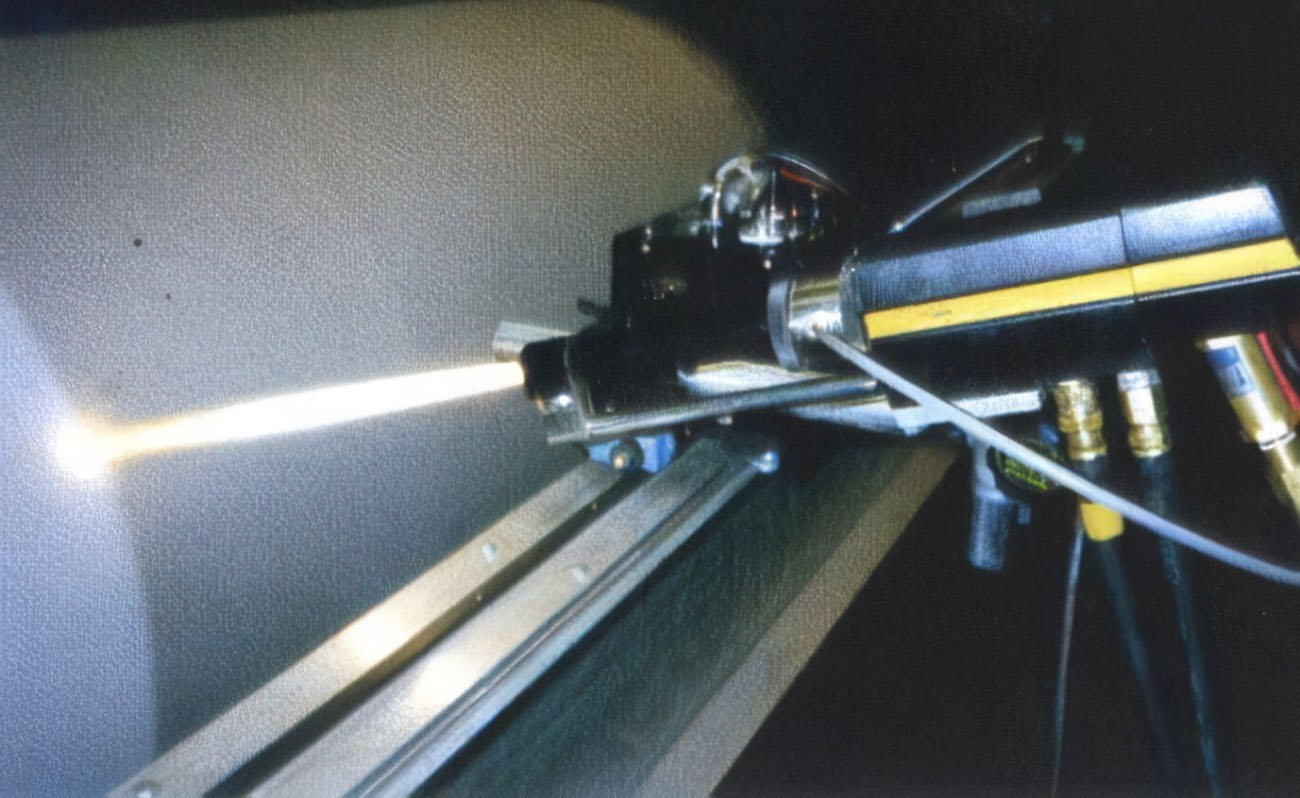

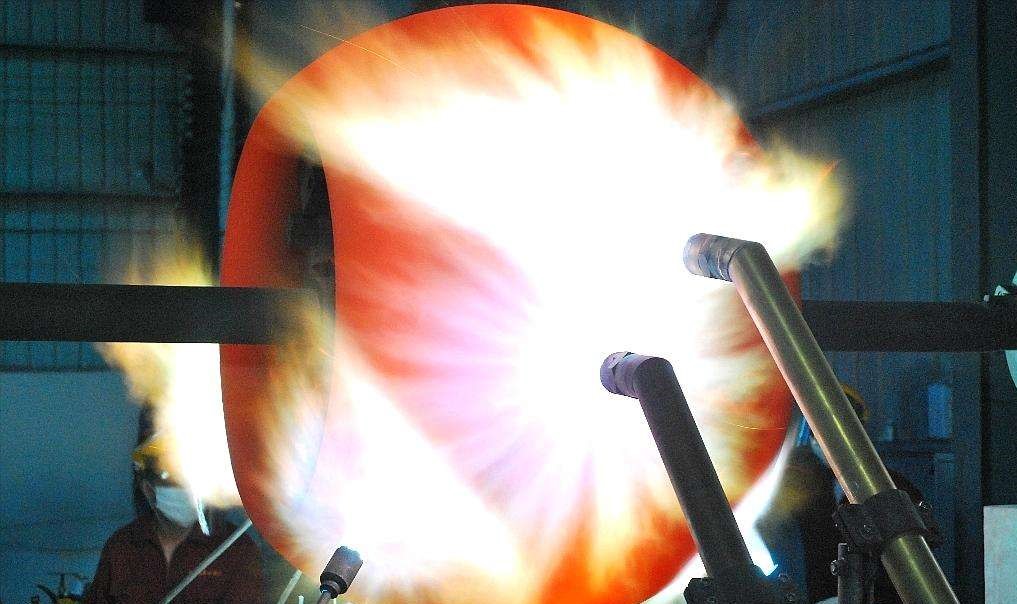

IV. Key Points of the Supersonic Velocity of Air (HVOF) Process

1. Powder Compatibility

- Use powders specifically designed for HVOF (particle size typically 15–45 μm), as opposed to plasma spray powders.

- Hygroscopic powders require pre-drying (120°C for 1 hour) to prevent porosity during spraying.

2. Process Advantages

- Supersonic flame velocity (>1500 m/s) and low temperature (approximately 2800°C) significantly reduce WC decarburization and decomposition (decomposition rate <16%, compared to 30% with conventional plasma spraying).

- Coating porosity can be controlled to <1.5%, increasing bonding strength by over 20%.

3. Parameter Example

- Typical parameters: Oxygen flow rate 56 m³/h, kerosene 28 L/min, spray distance 380 mm, uniform micro-nanostructured coating obtained.

V. Summary

WC-10Co4Cr, through its synergistic design of "tungsten carbide + cobalt-chromium metal phase," utilizes HVOF technology to create an ideal coating material that offers wear, corrosion, and oxidation resistance. Its performance advantages are particularly prominent in harsh operating conditions (such as energy drilling, offshore equipment, and aerospace). Future research is exploring the use of nanoparticles (e.g., adding 0.8–2 μm boron carbide) to enhance coating density and toughness.