Are you familiar with nickel-chromium carbide?

(Often referred to as NiCr-Cr₃C₂ composite powder) is a high-performance cermet material designed for high-temperature, corrosive, and wear-resistant environments. It consists of a nickel-chromium alloy (NiCr) binder phase and a chromium carbide (Cr₃C₂) hard phase. Its typical composition is 75% Cr₃C₂ + 25% NiCr (where NiCr is 80% Ni and 20% Cr). Coatings formed by high-velocity oxygen fuel (HVOF) or plasma spraying play an important role in protecting critical industrial components.

I. Material Composition and Structure

Duplex Composite Design:

Hard Phase Cr₃C₂: Has a melting point as high as 1810°C, excellent high-temperature hardness (microhardness 2200–2700 kg/mm²), and strong oxidation resistance (significant oxidation only begins at 1100–1400°C). NiCr binder phase: Provides toughness and corrosion resistance. The 80% Ni-20% Cr alloy composition forms a dense oxide film at high temperatures, enhancing corrosion and oxidation resistance.

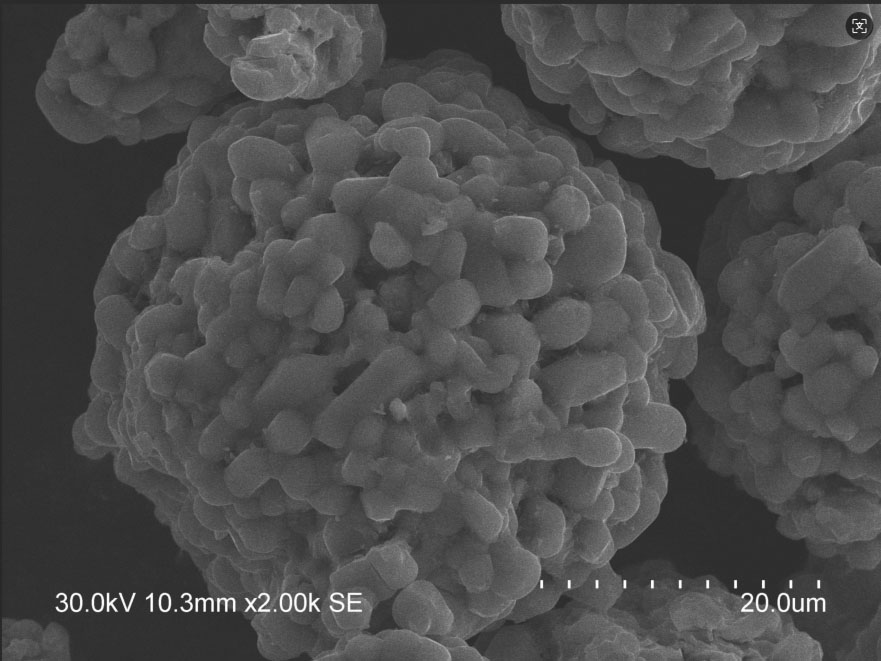

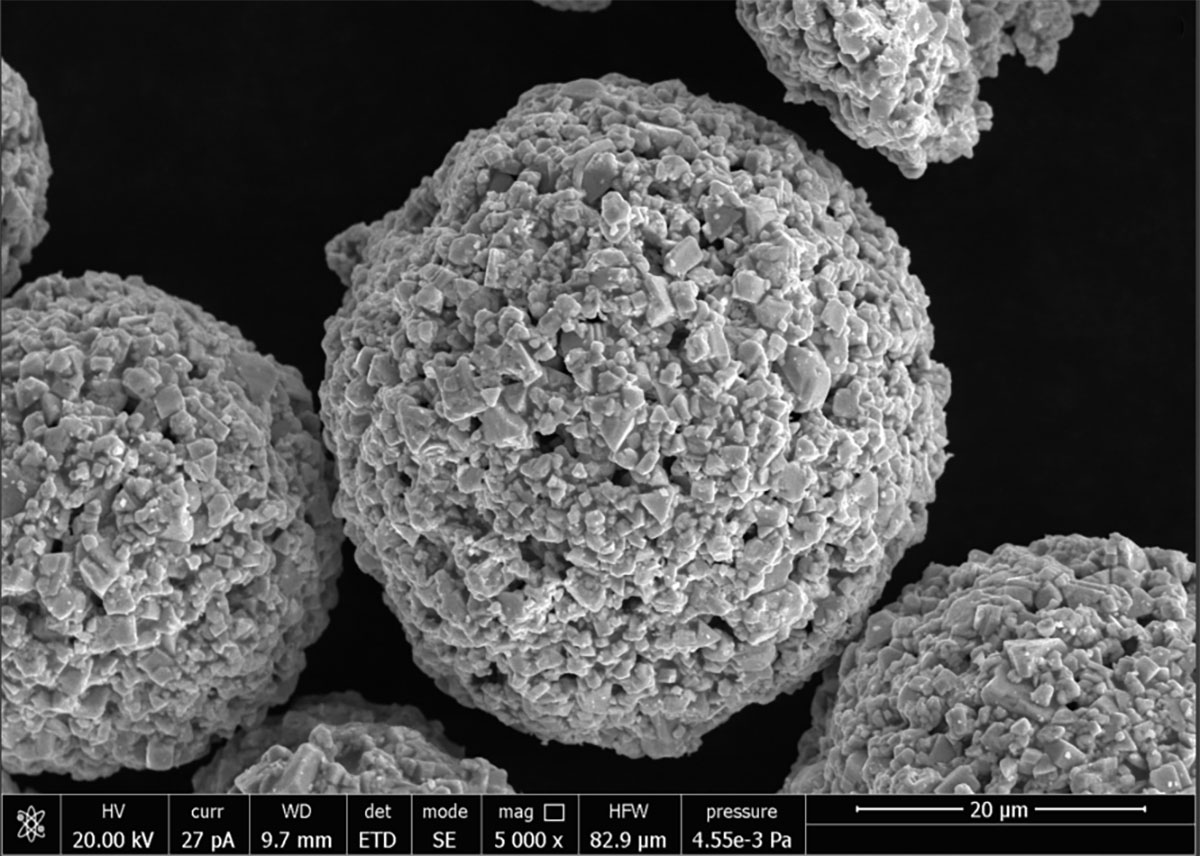

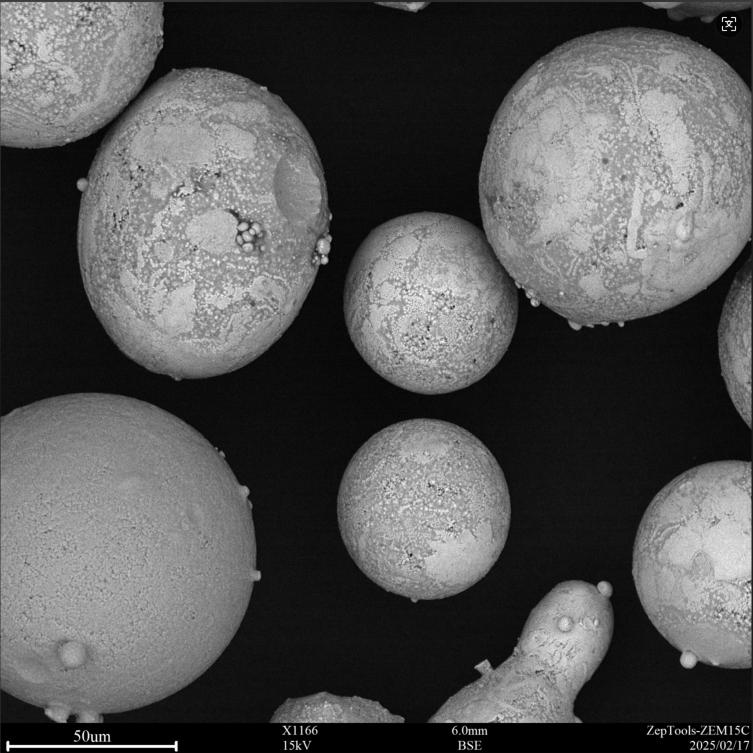

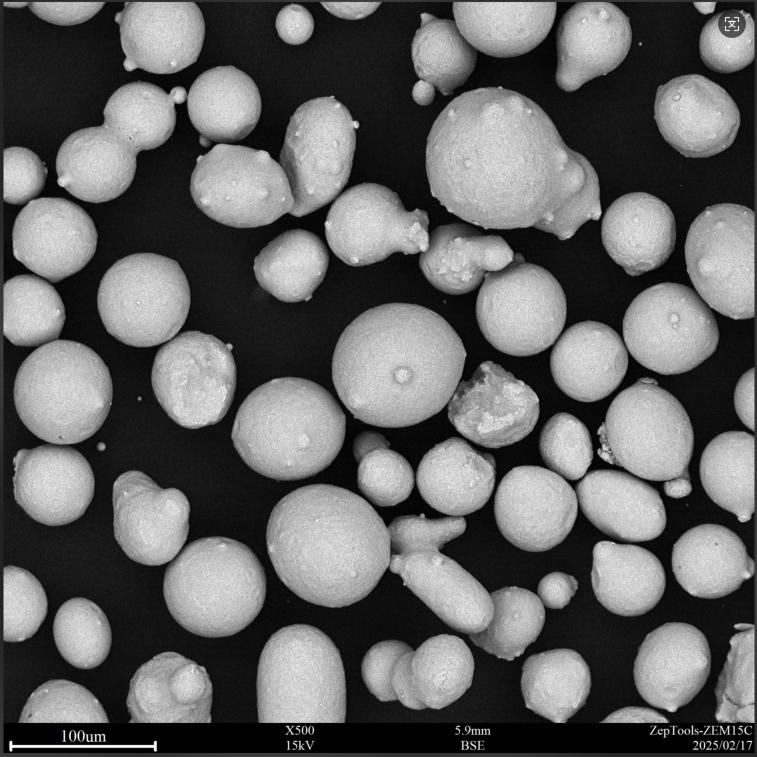

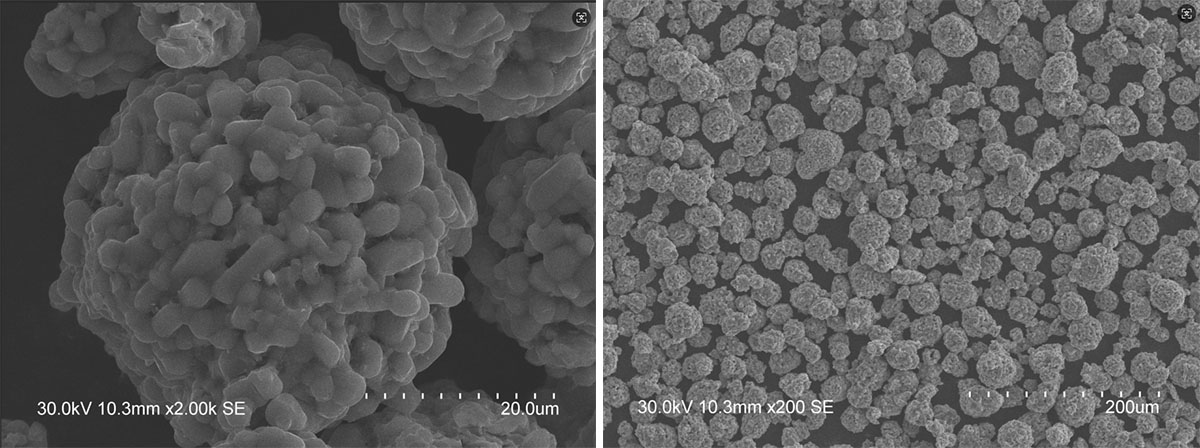

Powder Form: Produced through agglomeration and sintering processes, the powder typically has a particle size of 15–45 μm (for HVOF) or -325 mesh (for plasma spraying). Store away from moisture and dry at 120°C for one hour before use.

II. Core Performance Advantages

1. Extreme High-Temperature Stability

- Oxidation resistance reaches 900°C. After exposure to 982°C for 5 hours, it exhibits only slight discoloration, whereas WC-Co alloys or stainless steels experience severe oxidation failure.

- High hardness retention at high temperatures makes it suitable for thermal equipment such as gas turbines and boilers.

2. Excellent Corrosion Resistance

- In dilute sulfuric acid environments, its corrosion resistance is 30 times that of 1Cr18Ni9Ti stainless steel; in steam environments, its corrosion resistance is 50 times that of Co-WC alloys.

- Resistant to alkaline solution corrosion, suitable for papermaking and chemical equipment.

3. High Wear and Erosion Resistance

- After spraying on power plant boiler tube walls, annual wear is reduced from 1.5–2.0 mm to 0.03 mm, extending service life to over 7 years.

- Excellent resistance to erosion by sand-laden water flows, suitable for turbine blades and marine pump components.

4. Optimized Friction Performance (Self-Lubricating Variant)

- Adding Ni-coated MoS₂ (8–24%) creates a self-lubricating coating, reducing the friction coefficient from 0.72 to 0.45 and reducing wear weight loss by 36%.

III. Industrial Applications

1. Energy and Power Equipment

Boiler "Four-Tube" Protection: Water-wall tubes, superheaters, etc., are protected against coal ash erosion, increasing their service life by 7 times, reducing tube bursts.

Gas Turbines and Hydropower: Anti-cavitation coatings on blade seals and guide vanes, resistant to 800°C high-temperature gas.

2. Petrochemicals and Heavy Machinery

Drilling Tools: Drill collars and mud pump liners resist grit erosion and weak acid corrosion.

Valves and Compressors: Sealing surfaces and screw surfaces are reinforced to replace high-cost stainless steel components.

3. Papermaking and Textile Machinery

Drying Cylinder Roller Surfaces: Hardness reaches HRC 35–46, reducing scraper wear and extending the grinding cycle from six months to 3–4 years.

Gondola Rollers: Resists fiber friction and extends replacement cycles.

4. Aerospace and High-End Equipment

Engine Seal Runways: Compressor brush seals feature a bond strength of 43–47.6 MPa and self-lubricating properties.

Landing Gear Pins: Resist fretting wear and withstand high-load impacts.

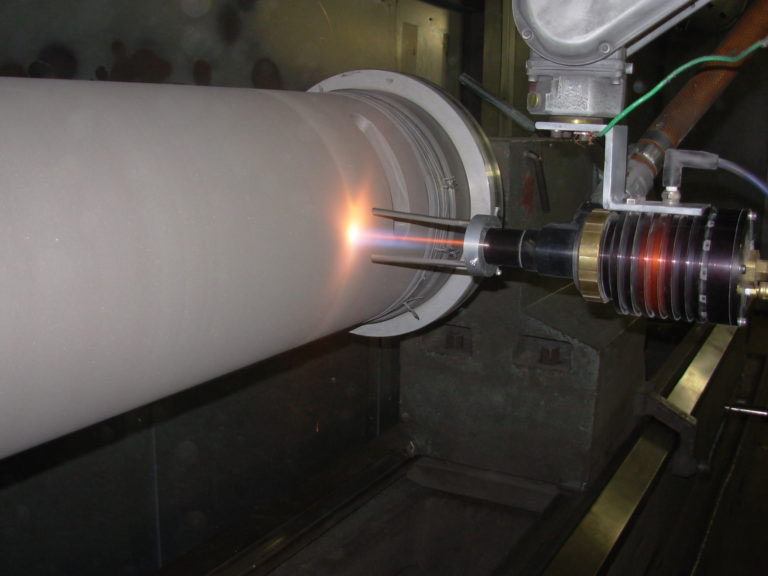

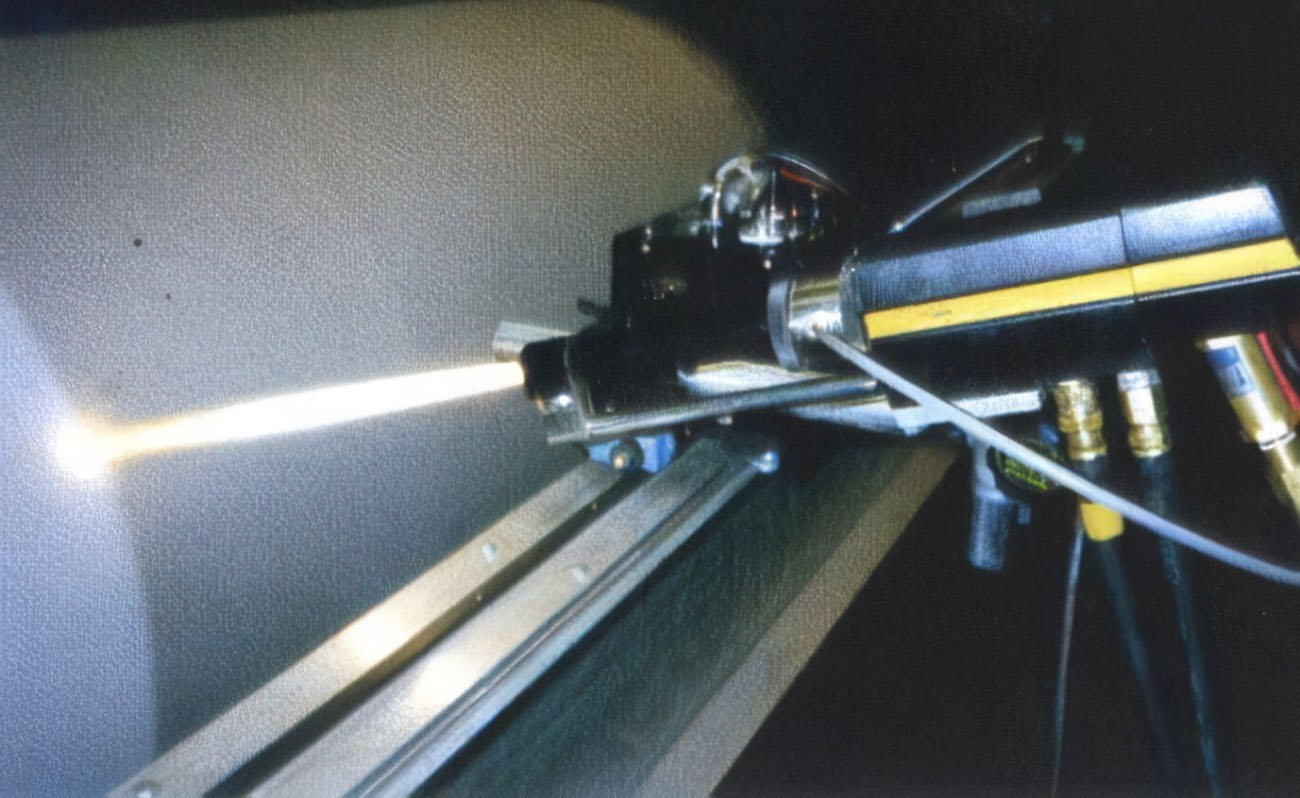

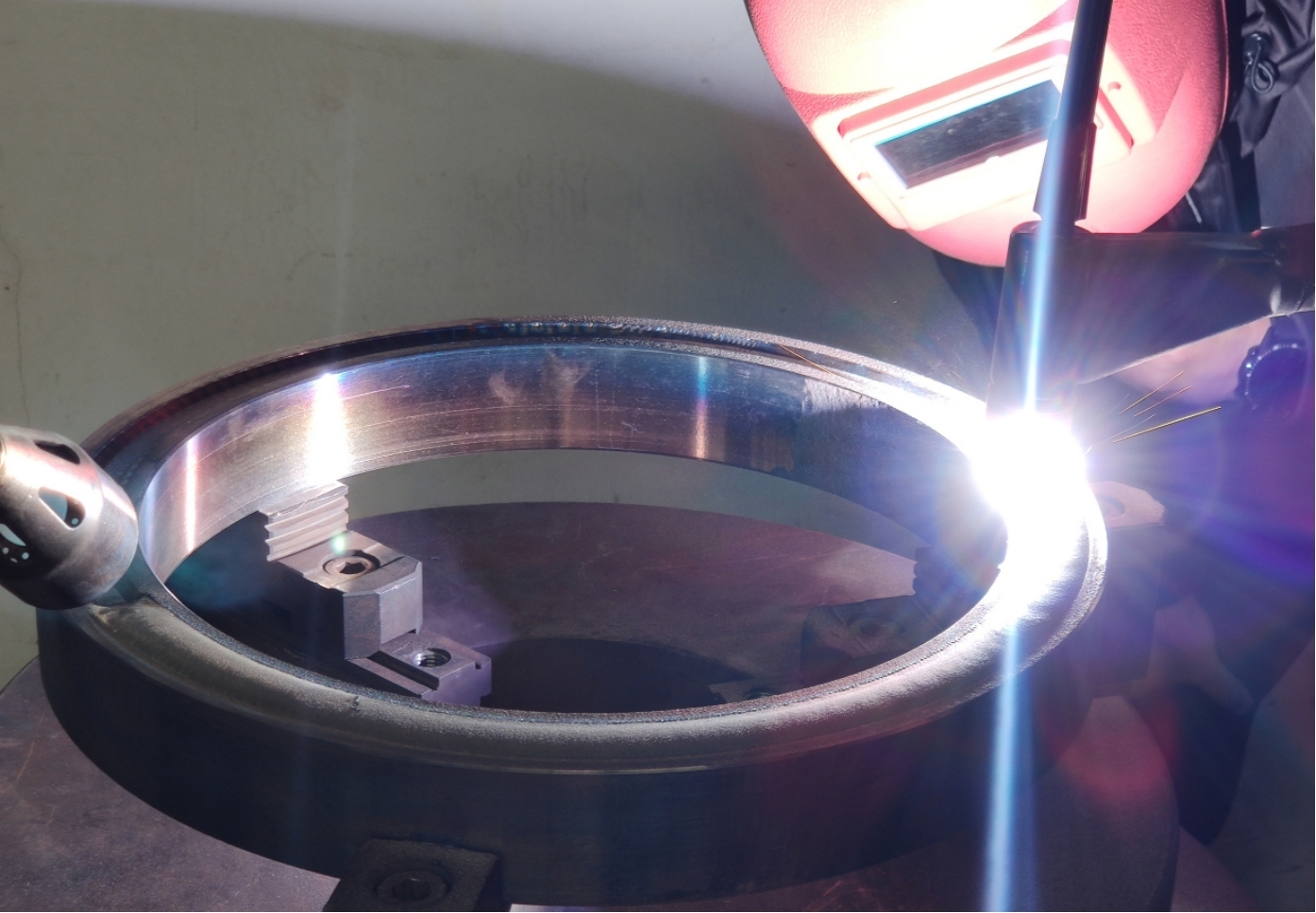

IV. Key Points in the Spraying Process

1. Powder Compatibility

- For HVOF, -325 mesh fine powder (particle size 15–45 μm) is preferred; for plasma spraying, -150/300 mesh is optional.

- Hygroscopic powders require preheating at 120°C for one hour to prevent porosity in the coating.

2. Parameter Optimization

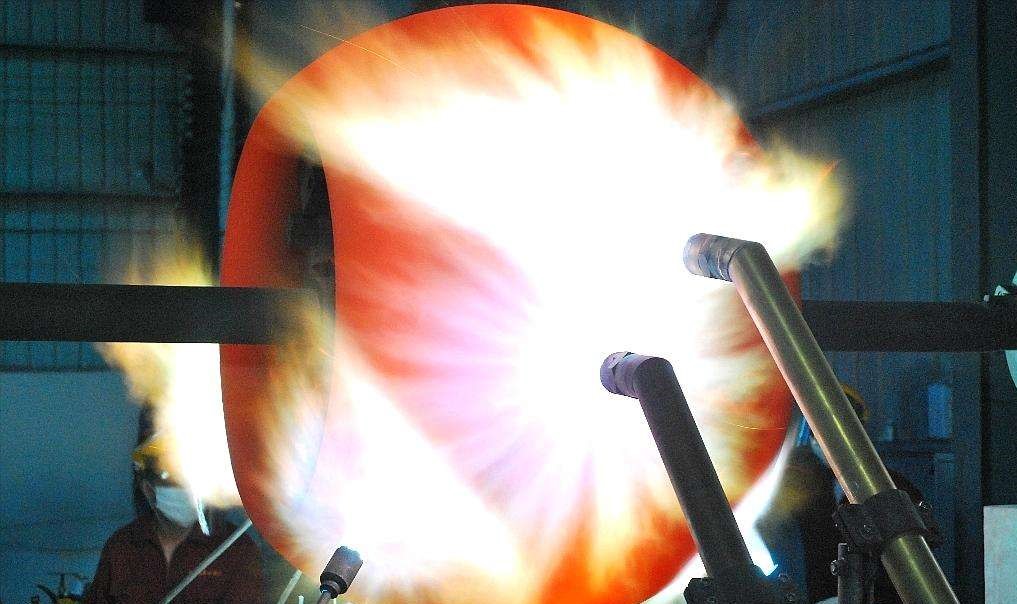

HVOF process: Flame velocity 1500–2000 m/s, temperature 2800–3100°C, suppressing Cr₃C₂ decomposition (decomposition rate <16%).

- Typical parameters: Oxygen pressure 0.9 MPa, propane pressure 0.4 MPa, spray distance 180–380 mm.

3. Substrate Pretreatment

- Sandblast to Sa3 grade, with a roughness of 50–80 μm. Spraying should be completed within 3–4 hours of sandblasting.

V. Innovation Directions and Trends

Self-lubricating Composites: Adding solid lubricants such as Ni-coated MoS₂/BaF₂ reduces the coefficient of friction (e.g., in aerospace seals).

Nano-enhancement: Introducing B₄C or nano-Cr₃C₂ (0.8–2 μm) improves coating density and toughness.

Intelligent Processing: Real-time monitoring of flame temperature and particle velocity reduces coating porosity (target: <1%).

Summary

Nickel-chromium carbide coatings, through their collaborative design of a "Cr₃C₂ hard phase + NiCr binder phase," are an ideal solution for addressing the triple failure of high temperature, corrosion, and wear. Their proven application in energy, aviation, and heavy industry has proven their long-term protective value. Future development will focus on multifunctional composites and precision processing to continuously overcome bottlenecks in protection under extreme working conditions.