Applications of Supersonic Sprayed Nickel-Chromium-Chromium Carbide Coatings

Supersonic sprayed nickel-chromium-chromium carbide (NiCr-Cr₃C₂) coatings, with their excellent high-temperature wear, corrosion, and erosion resistance, play an important role in protecting key components in various industrial sectors. The following is an analysis of typical application scenarios and actual results:

I. Energy and Power Equipment

1. Boiler "Four-Tube" Protection

- In thermal power plants and fluidized bed boilers, water-wall tubes, superheater tubes, reheater tubes, and economizer tubes are subject to long-term erosion by high-temperature flue gas and coal ash, resulting in annual wear of up to 1.5-2.0 mm.

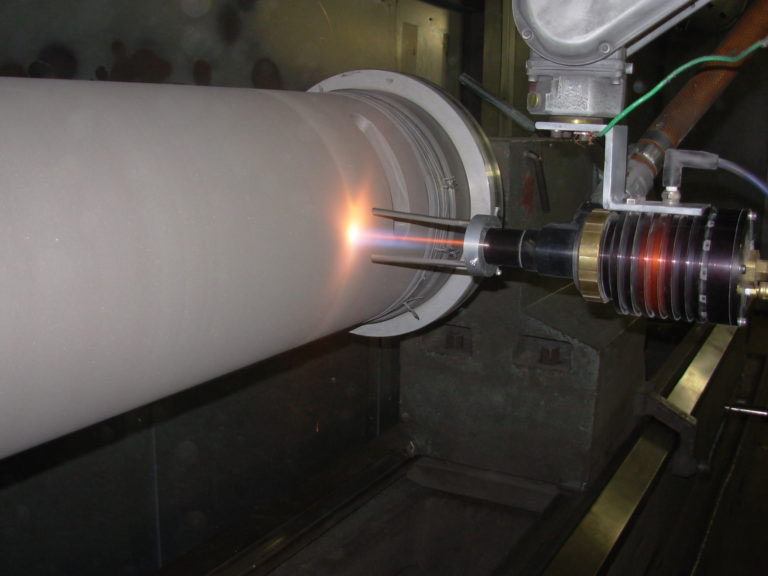

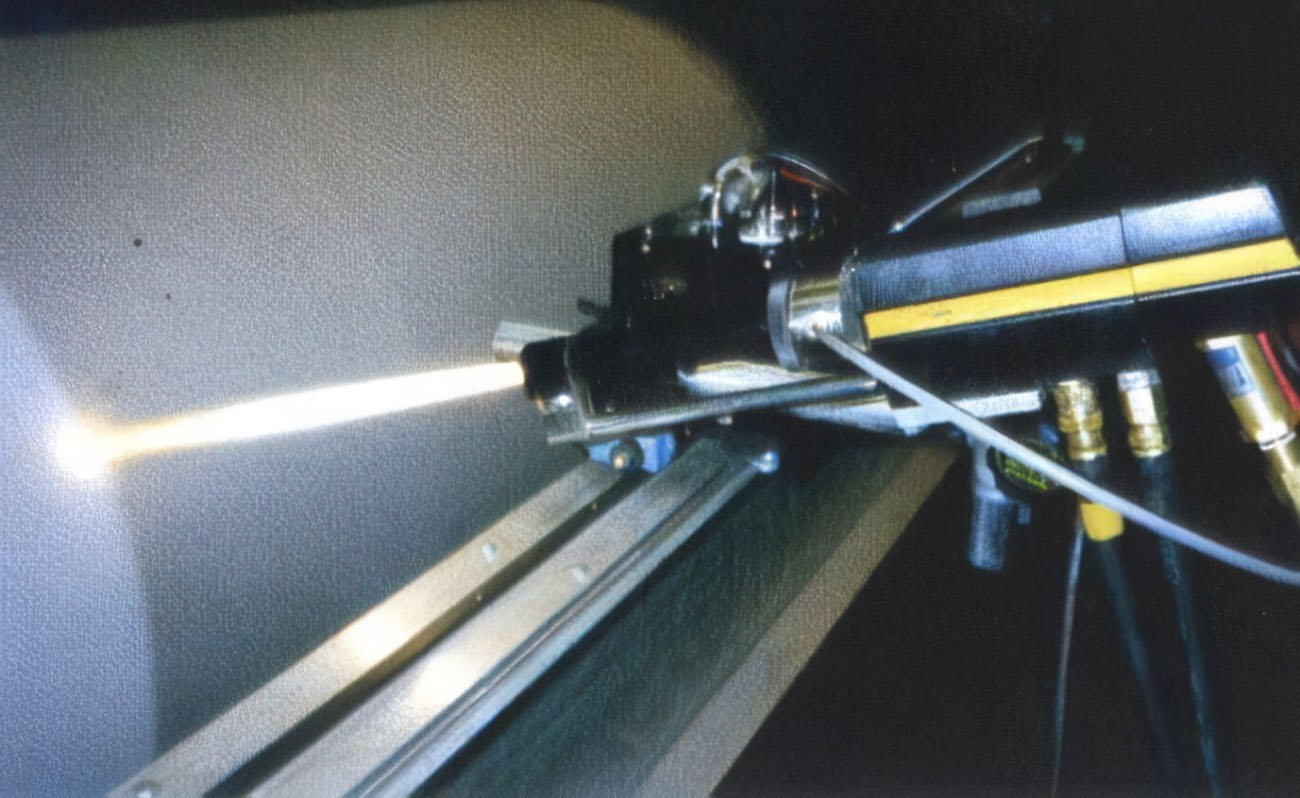

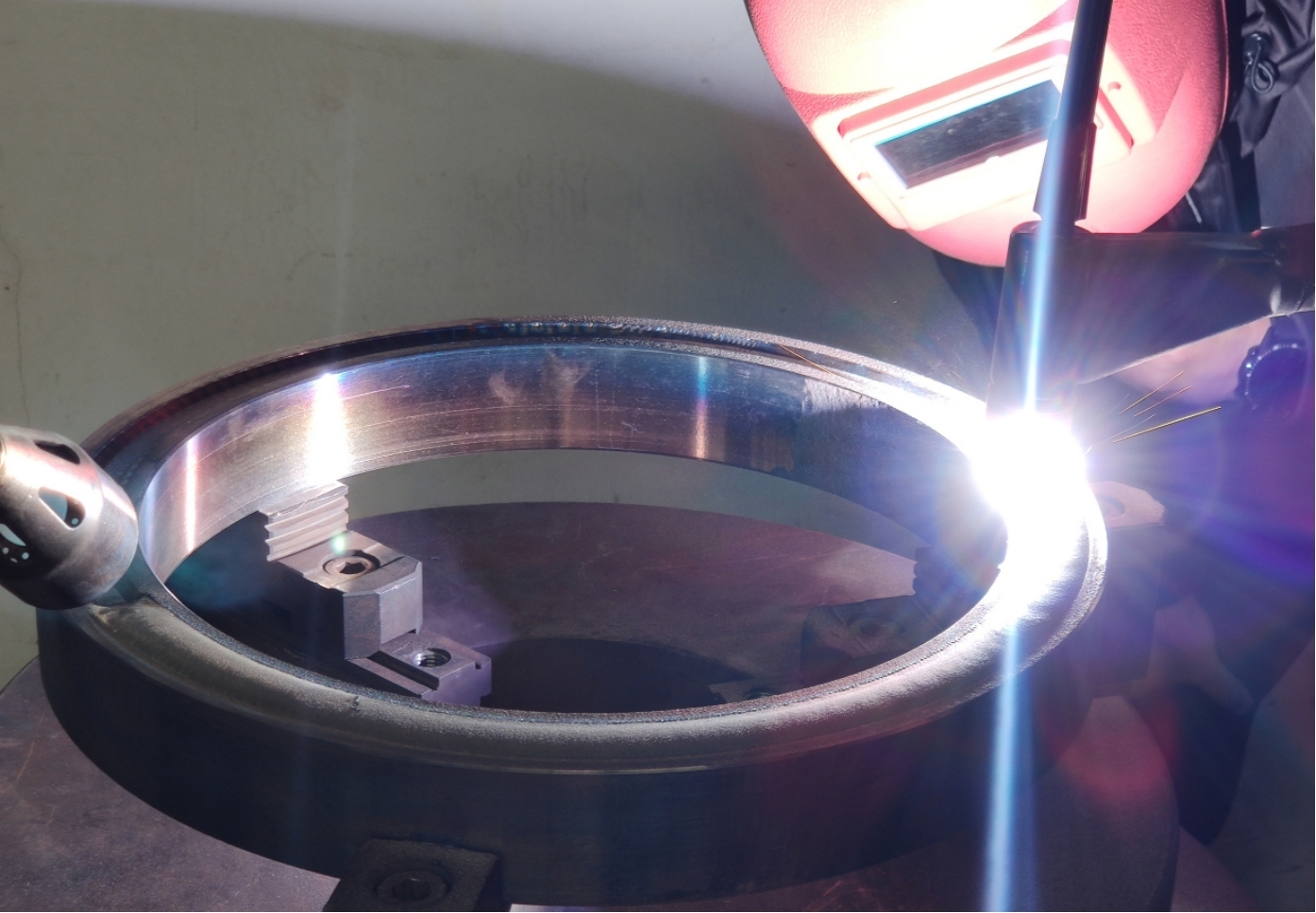

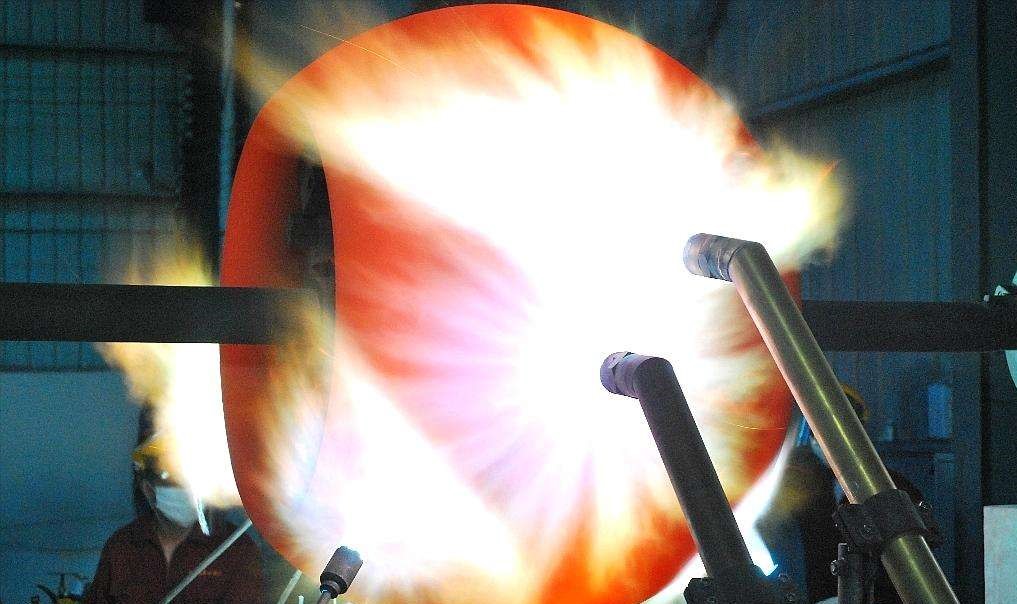

- After spraying NiCr-Cr₃C₂ coatings (thickness 0.3-0.6 mm), wear is reduced to 0.03-0.2 mm/year, extending service life to over seven years and reducing unplanned downtime caused by tube bursts. Typical process: Supersonic arc spraying (HVOF) using a coated powder with a Cr₃C₂ content of 75%-80% to enhance coating homogeneity and decarburization resistance.

2. Turbine and Gas Turbine Components

- Flow-through components such as turbine blades and guide vanes are susceptible to cavitation and erosion damage in sand-laden water.

- By adding elements such as Nb and Ta (1-5%), the coating improves fretting wear and cavitation resistance, making it suitable for hydropower and gas turbine blades.

II. Aerospace and High-End Equipment

1. Engine Brush Seal Runways

- In compressor and turbine rotor seals, the coating must possess both high bond strength (43-47.6 MPa) and self-lubricating properties.

- Adding solid lubricants such as CaF₂/BaF₂ (the remainder) creates a high-temperature self-lubricating coating, reducing brush friction loss and adapting to operating conditions below 800°C. - Example process parameters: spray distance 340-360 mm, oxygen flow rate 1750-1800 L/h, kerosene flow rate 5.3-5.5 gal/h.

2. High-temperature alloy component protection

- Used on compressor blade tenons, landing gear pins, etc., to resist fretting wear and high-temperature oxidation.

III. Petrochemical and Heavy Machinery

1. Drilling and Fluid Equipment

- Components such as oil drill collars, centralizers, and mud pump liners face a dual attack from grit erosion and corrosive media.

- The coating's corrosion resistance is 30 times that of stainless steel (in a dilute sulfuric acid environment), increasing erosion wear life by 3-5 times.

- For valve sealing surfaces and chemical pump impellers, it resists the synergistic effects of weak acid media and particle wear.

2. Compressor and Screw Repair

- Spraying on compressor screws and hydraulic cylinder piston rods reduces friction and wear, replacing high-cost stainless steel components.

IV. Papermaking and Textile Machinery

1. Drying Cylinders and Roller Components

- After spray coating, the surface hardness of papermaking dryer cylinders reaches HRC35-46 (HB330-420), reducing the coefficient of friction and blade wear. This reduces the grinding cycle from six months to 3-4 years, increasing paper production by 30%.

- Rollers and godet rollers in textile machinery are reinforced with coatings, significantly extending their wear life.

2. Plate Heat Exchanger Corrosion Protection

- Wide-channel heat exchanger plates are sprayed with a 0.3-0.5 mm coating to address corrosion issues caused by alkaline solutions and extend maintenance intervals.

V. Key Points in Process Implementation

1. Powder Selection

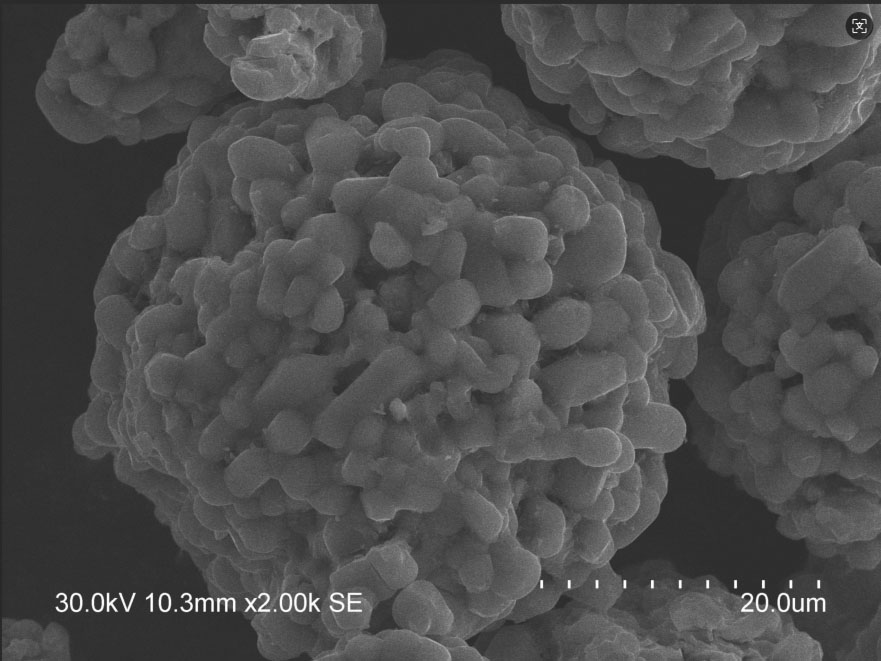

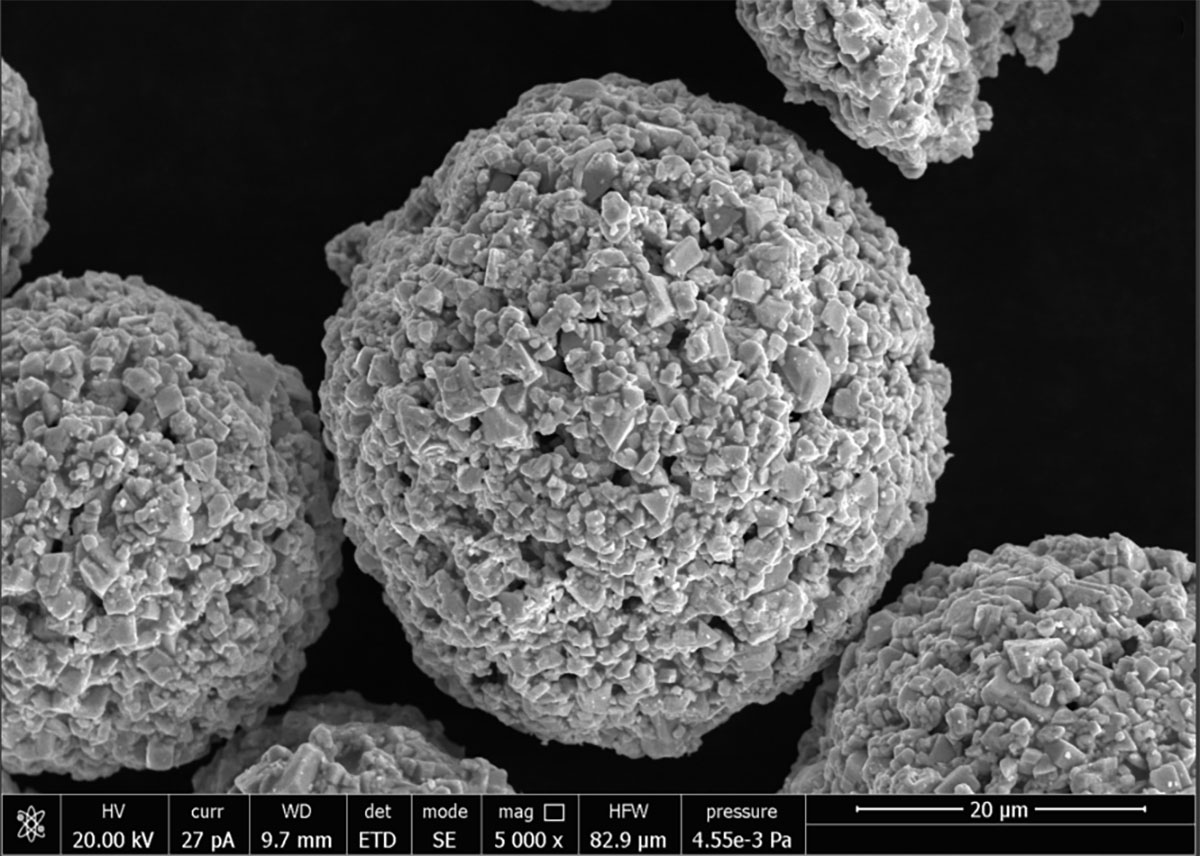

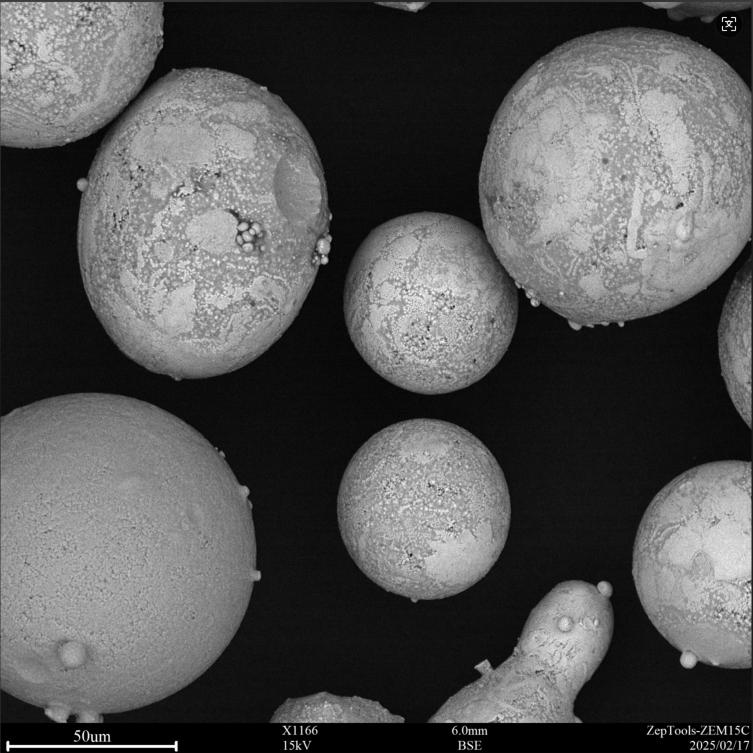

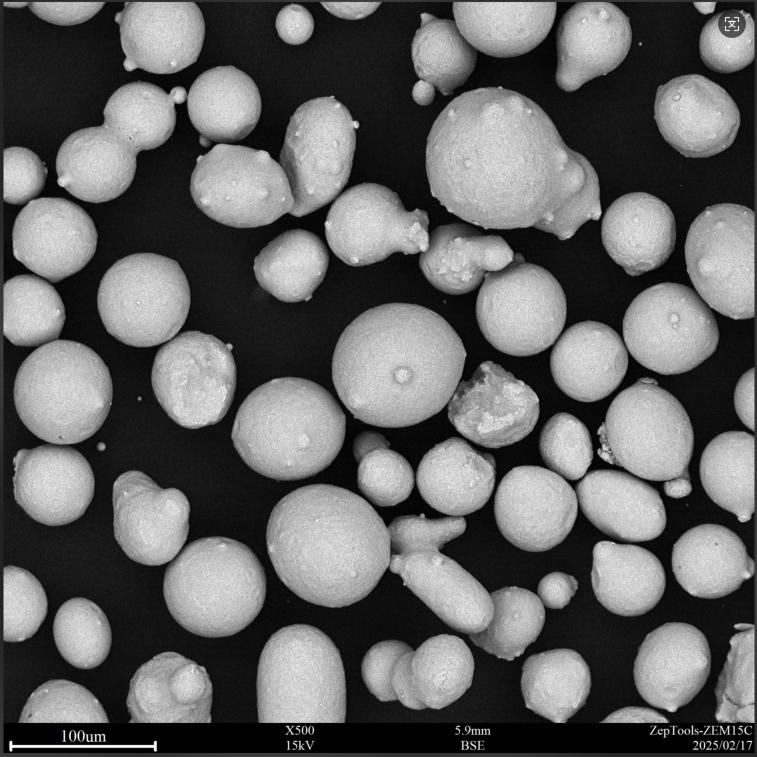

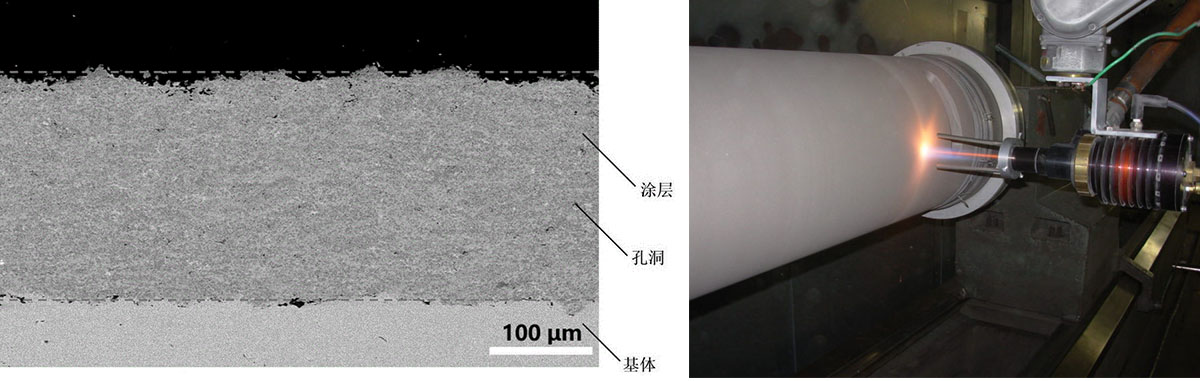

- Coated powders (75-80% Cr₃C₂ + 20-25% NiCr) are preferred, with a particle size of ≥70% -325 mesh and a flowability of <110 s/50g. - Preheating at 120°C for one hour in humid environments prevents porosity.

2. Surface Pretreatment

- Sandblasting to Sa3 grade, with a roughness of 50-80 μm. Spraying should be completed within 3-4 hours after sandblasting.

3. Spraying Parameter Control

- HVOF flame velocity of 1500-2000 m/s and temperature of 2900-3100°C to inhibit carbide decomposition (decomposition rate <16%).

Summary

Nickel-chromium carbide coatings, through their "hard phase + binder phase" synergistic design (Cr₃C₂ for wear resistance + NiCr for corrosion resistance), and powered by supersonic spraying technology, are ideal for addressing the coexistence of high temperatures, corrosion, and wear. Their applications already cover core sectors such as energy, aviation, and heavy industry. Future developments will include nanocomposites (such as the addition of B₄C) and intelligent processes to further overcome the bottleneck of long-term protection in extreme environments.