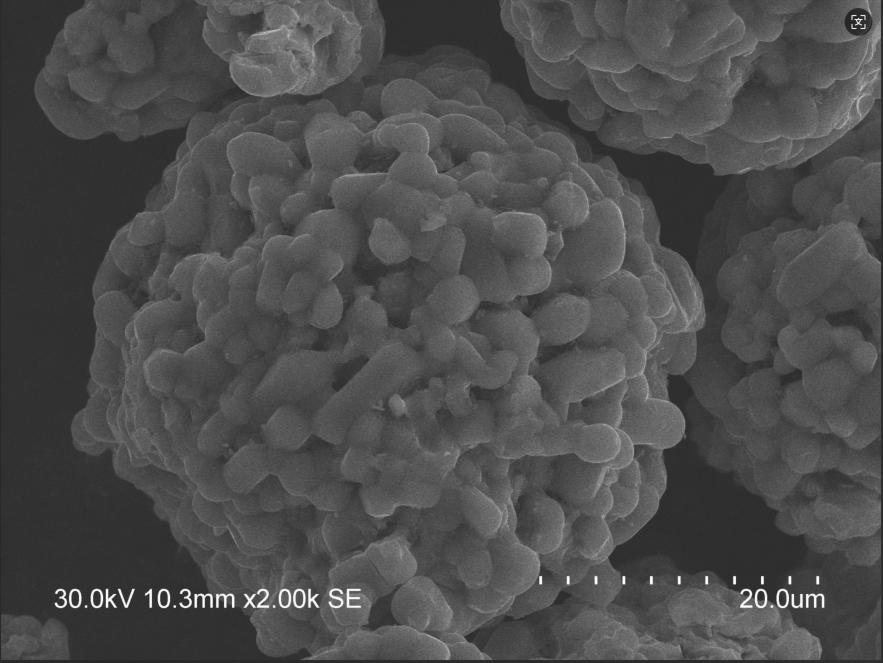

What is nickel-chromium carbide?

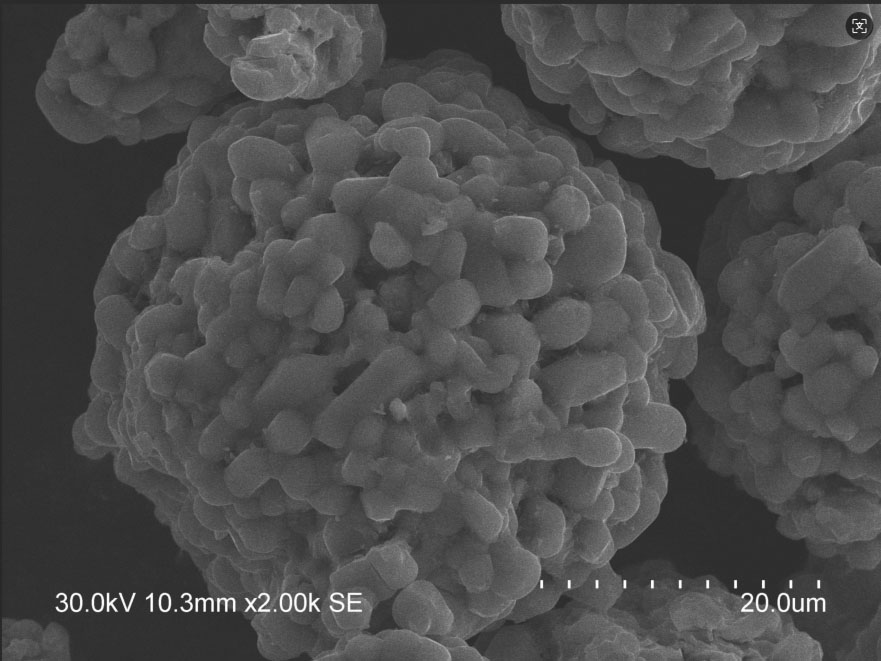

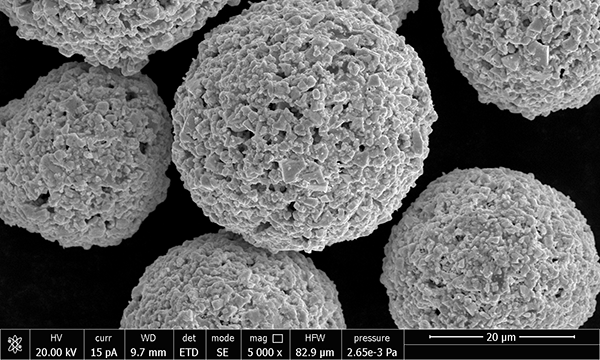

Nickel-chromium carbide is a high-temperature wear-resistant metal-ceramic composite material, mainly composed of nickel-chromium (NiCr) alloy bonding phase and chromium carbide (Cr3C2) hard particles. The typical ratio is 75% nickel-chromium + 25% chromium carbide (NiCr-25%Cr3C2), and the ratio can be adjusted according to the working conditions.

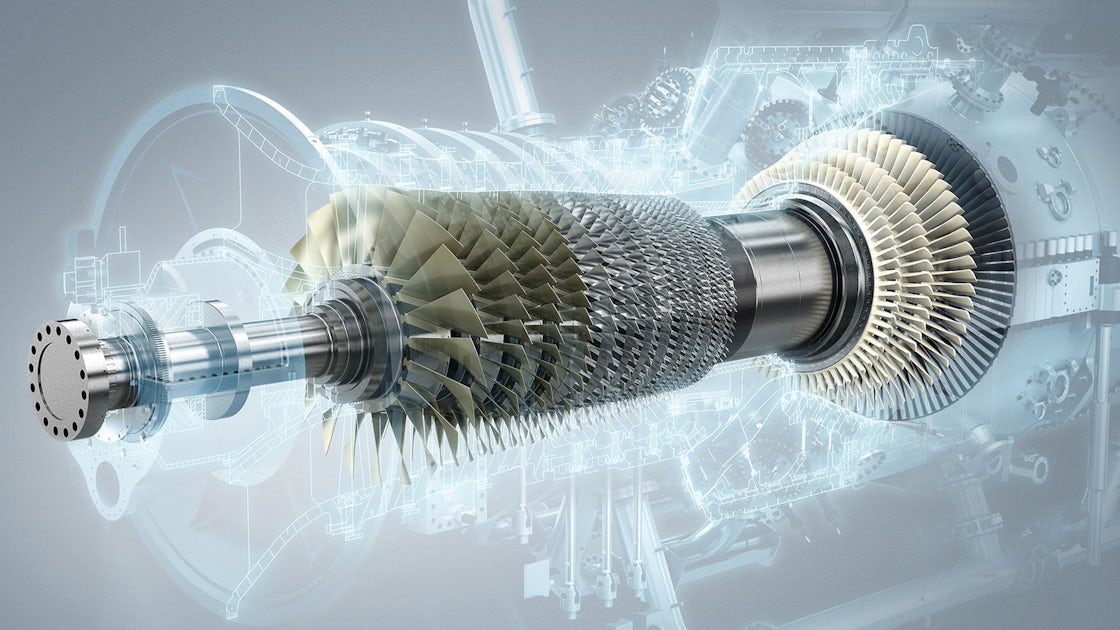

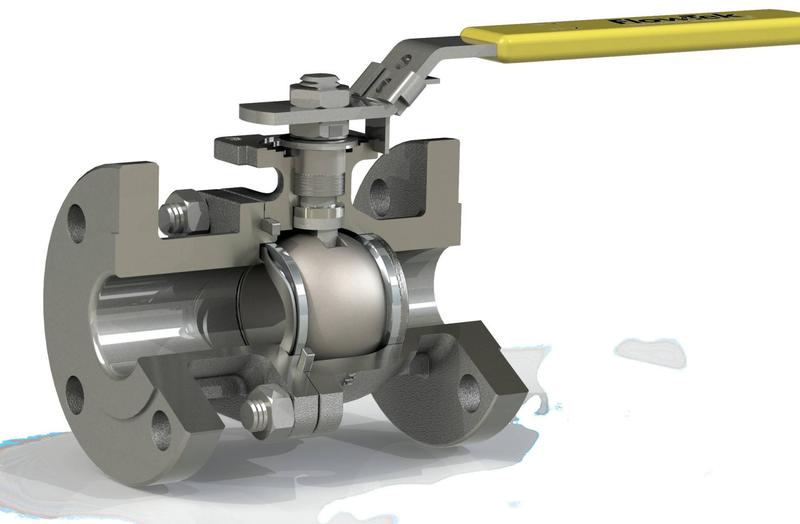

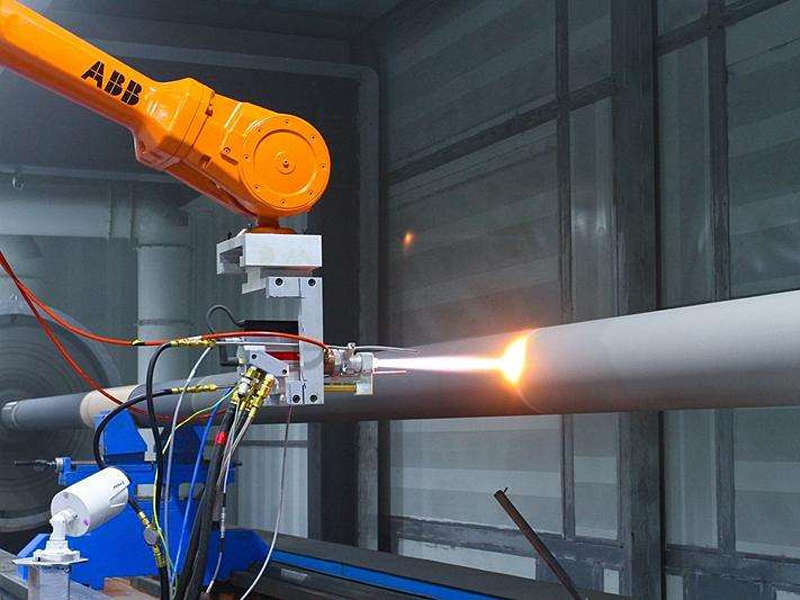

What are the applications of HVOF nickel-chromium carbide?

What are the main applications of the welding layer of cobalt-based self-fluxing alloy?

What are the main applications of nickel-based self-fluxing alloy welding layers?

Laser cladding nickel-based high-temperature alloy Inconel625

Inconel 625 is a nickel-chromium-molybdenum-niobium (Ni-Cr-Mo-Nb) high-temperature alloy, the specific composition is: Nickel (Ni): ≥58% (matrix, providing high temperature strength and corrosion resistance)...

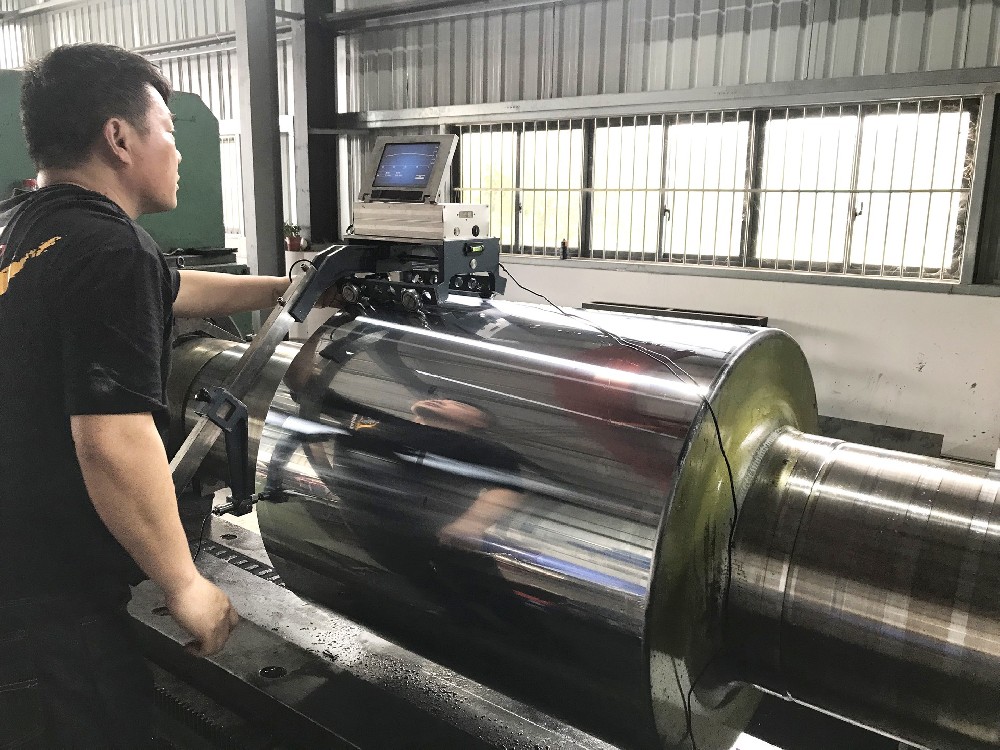

Ni60CuMo is a better material than Ni60A

Ni60CuMo is a reinforced material improved by adding copper (Cu) and molybdenum (Mo) elements to the standard Ni60 (NiCrBSi) alloy, which mainly improves corrosion resistance, thermal conductivity and high temperature stability.

What are the applications of supersonic sprayed tungsten carbide coatings?

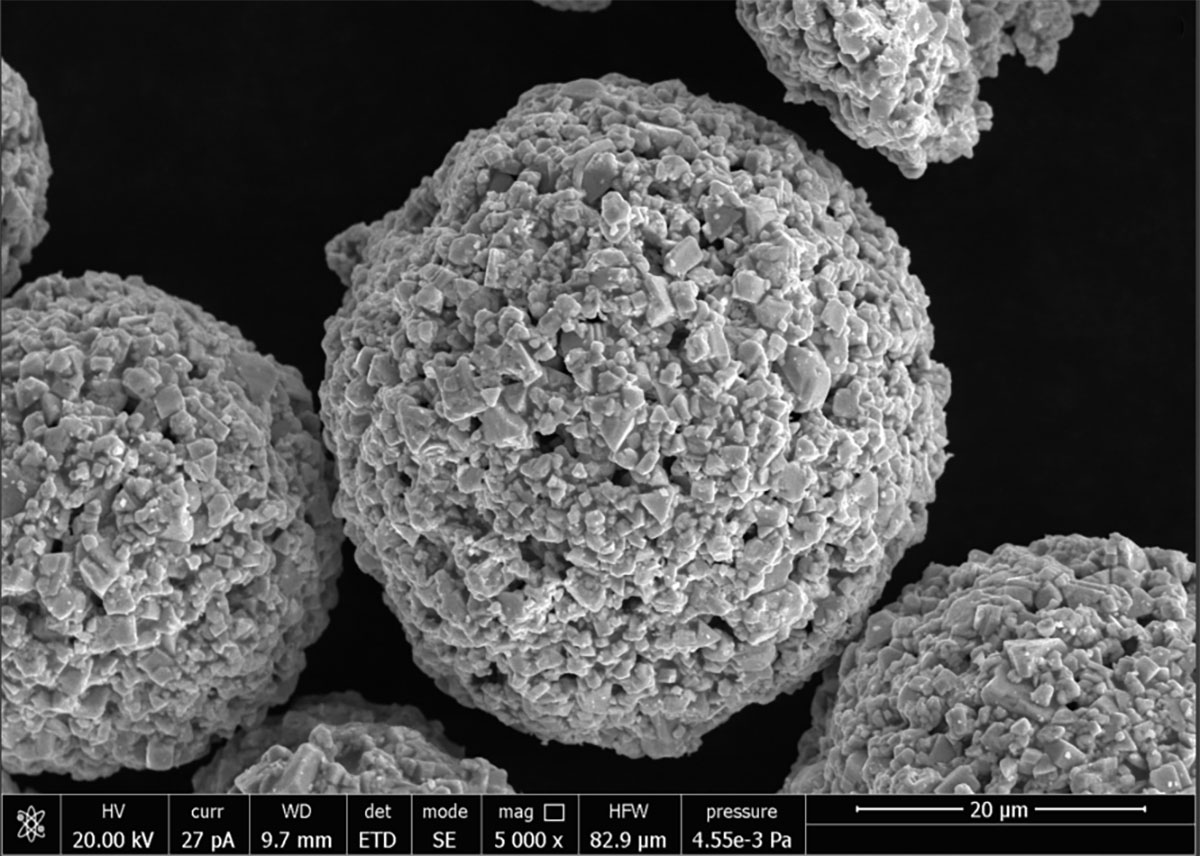

What is WC-10Co4Cr?

Characteristics of Supersonic Sprayed Tungsten Carbide

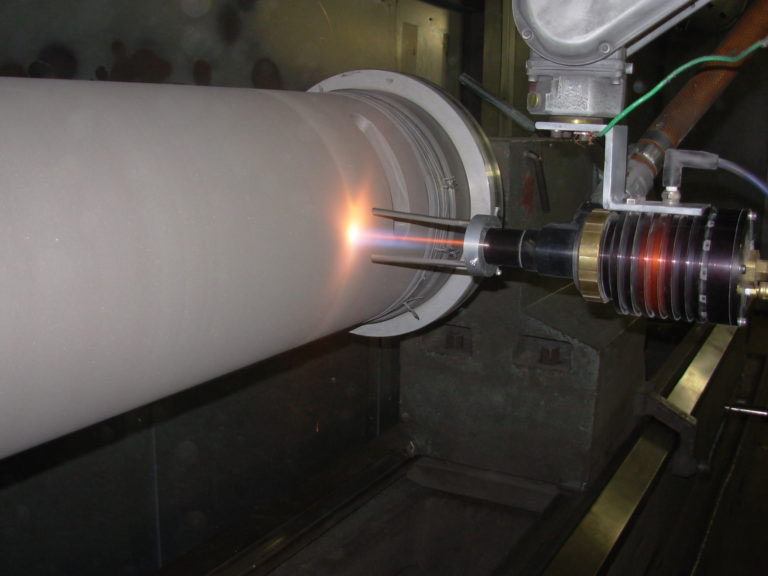

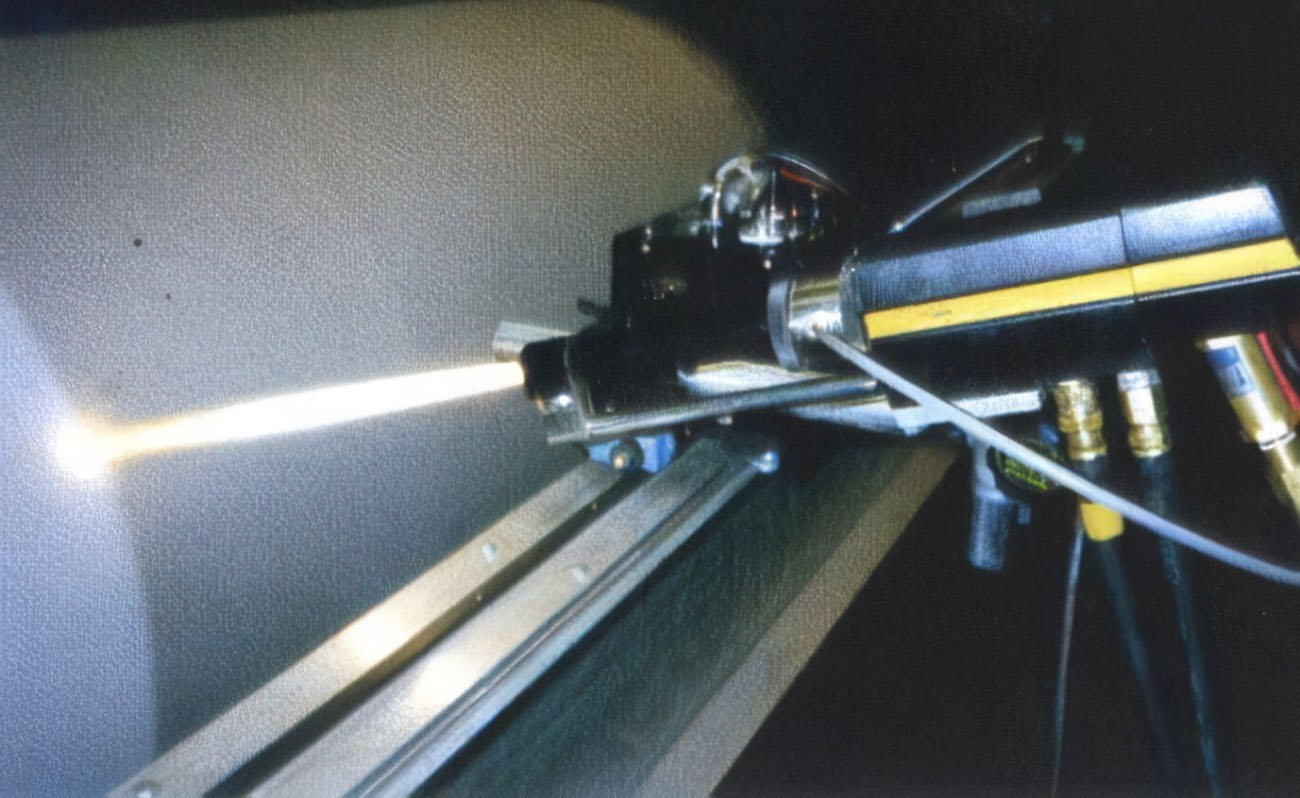

Supersonic flame spraying is an advanced thermal spraying technology that has gained significant attention in the field of materials surface treatment. This technique is particularly effective for creating coatings that require high wear resistance and corrosion resistance.

WC-20CrC-7Ni Composite Material: An Overview

Today, we will explore a remarkable composite powder known as WC-20CrC-7Ni, which is composed of tungsten carbide (WC), chromium carbide (CrC), and nickel carbonyl. This composite material is designed to offer exceptional properties, including corrosion resistance, wear resistance, and high-temperature stability.