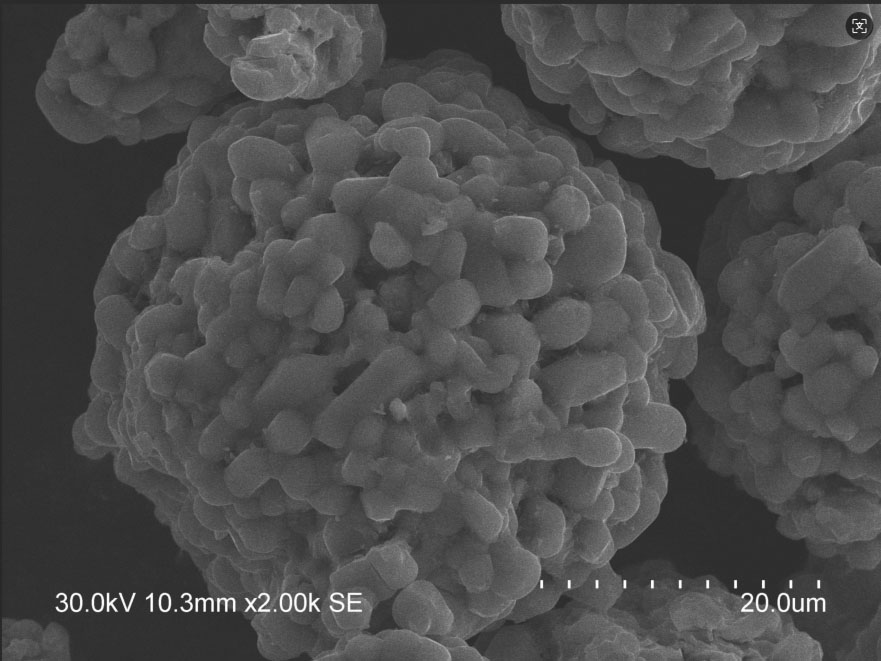

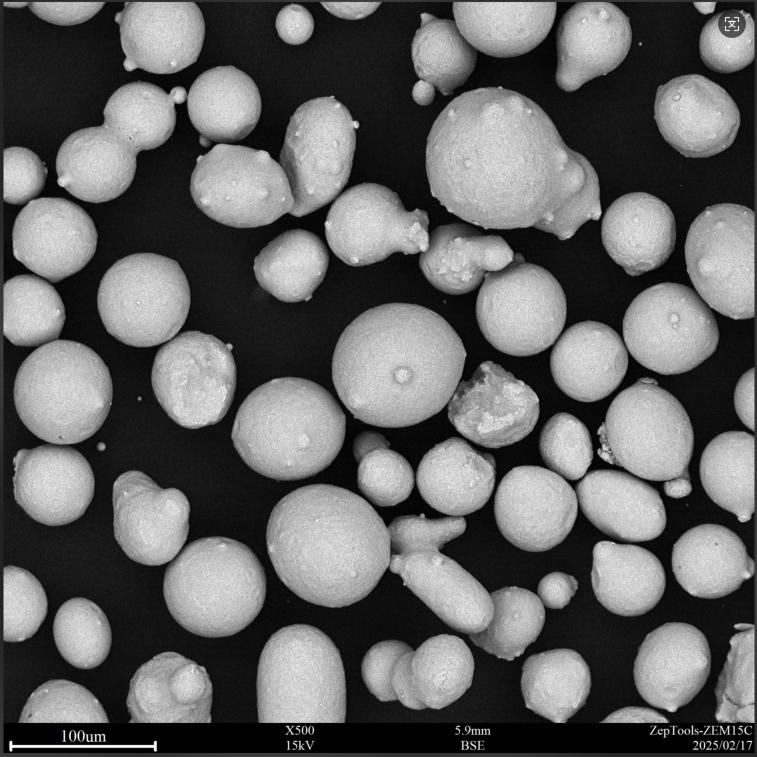

Are you familiar with nickel-chromium carbide?

(Often referred to as NiCr-Cr₃C₂ composite powder) is a high-performance cermet material designed for high-temperature, corrosive, and wear-resistant environments.

Applications of Supersonic Sprayed Nickel-Chromium-Chromium Carbide Coatings

Supersonic sprayed nickel-chromium-chromium carbide (NiCr-Cr₃C₂) coatings, with their excellent high-temperature wear, corrosion, and erosion resistance, play an important role in protecting key components in various industrial sectors.

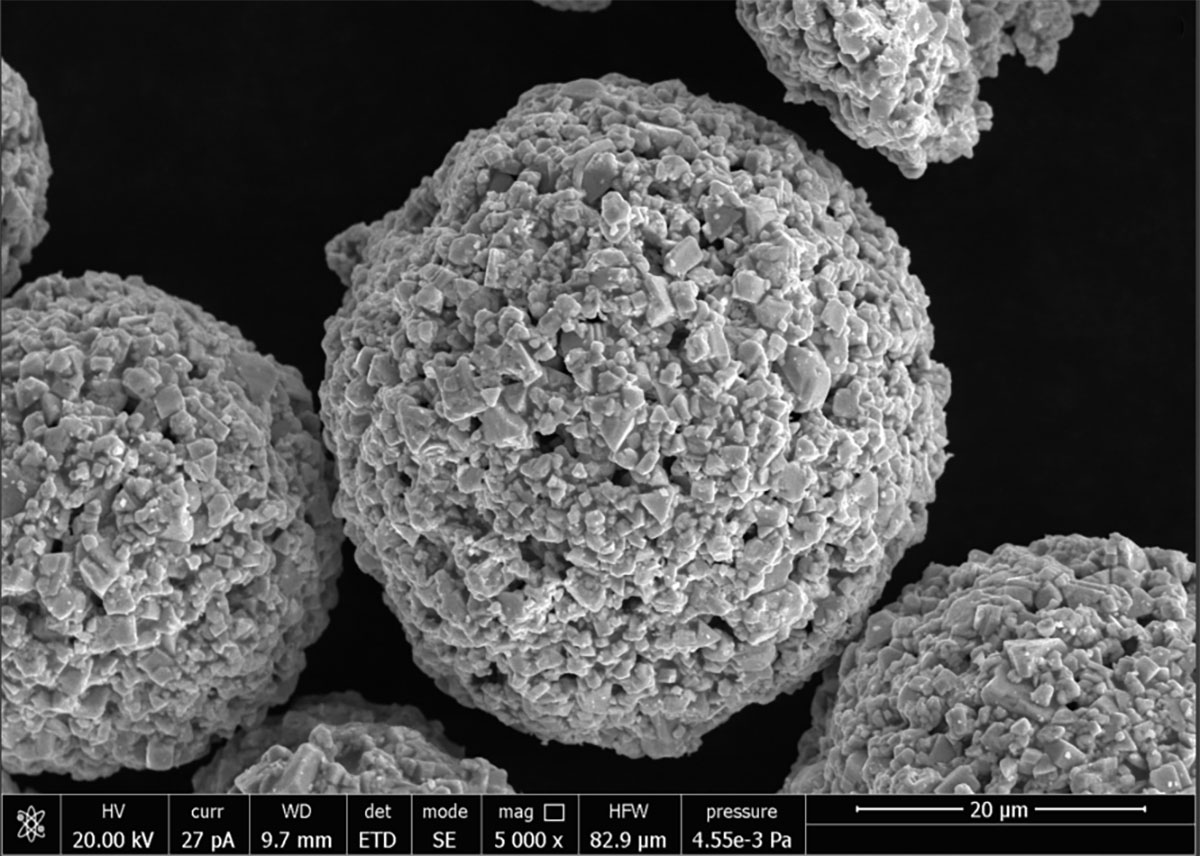

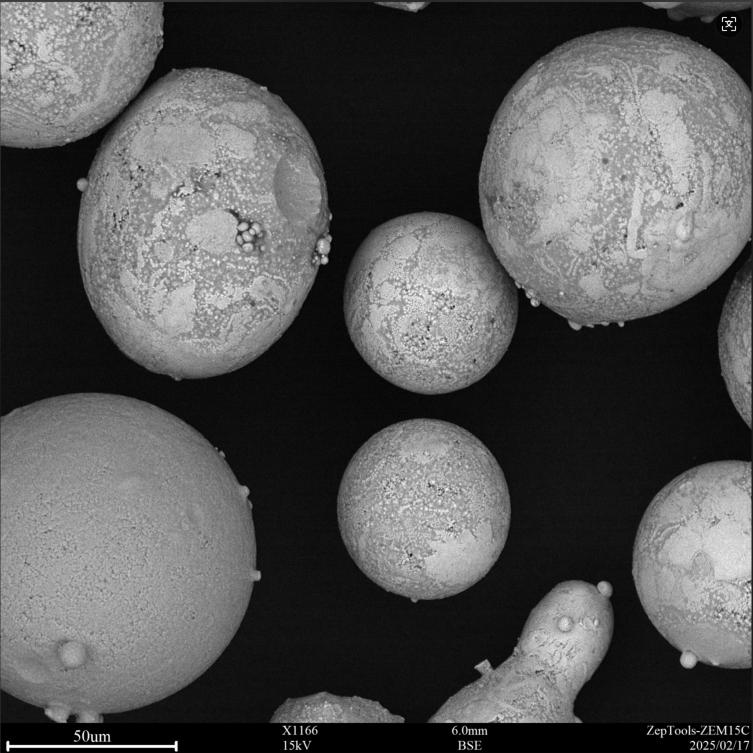

Are you familiar with WC-10Co4Cr?

WC-10Co4Cr (86% WC, 10% Co, 4% Cr) is a tungsten carbide-based alloy powder produced through agglomeration and sintering.

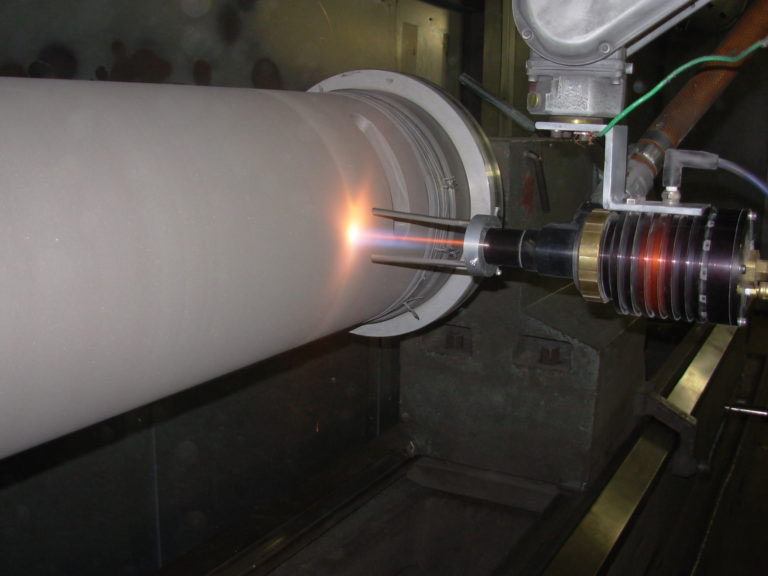

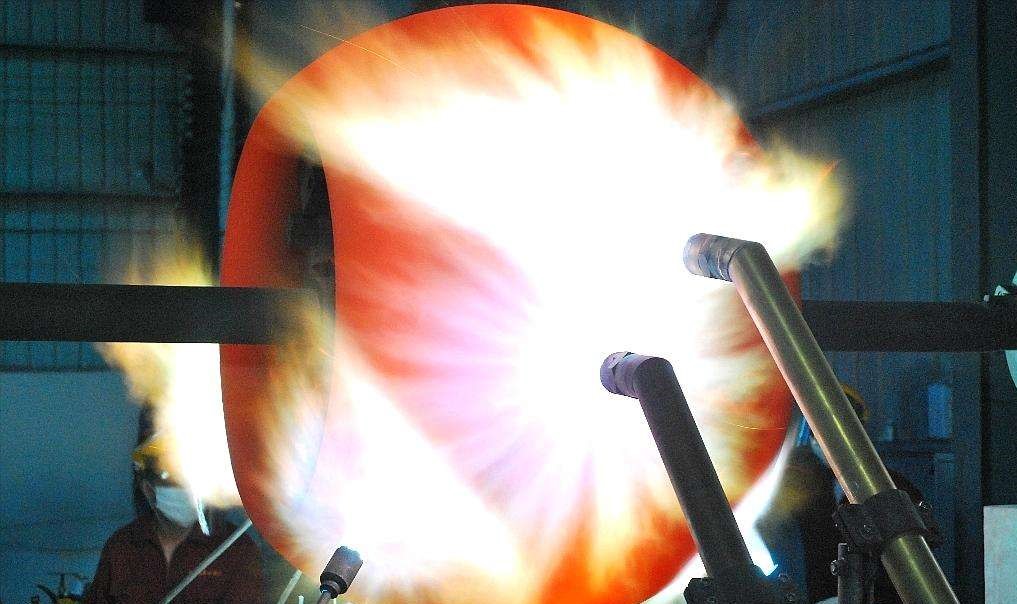

What are the applications of tungsten carbide coatings produced by high velocity oxygen fuel spraying?

Tungsten carbide coatings produced by high velocity oxygen fuel spraying (HVOF) have been widely and maturely applied in numerous industrial fields due to their excellent performance.

Laser cladding nickel-based high-temperature alloy Inconel625

Inconel 625 is a nickel-chromium-molybdenum-niobium (Ni-Cr-Mo-Nb) high-temperature alloy...

What are the applications of plasma surfacing nickel-based tungsten carbide?

Plasma surfacing nickel-based tungsten carbide (Ni-WC) is widely used in key components in multiple industrial fields due to its comprehensive performance of high wear resistance, impact resistance and corrosion resistance.

What is nickel-based tungsten carbide?

Introduction to nickel-based tungsten carbide (Ni-WC) materials

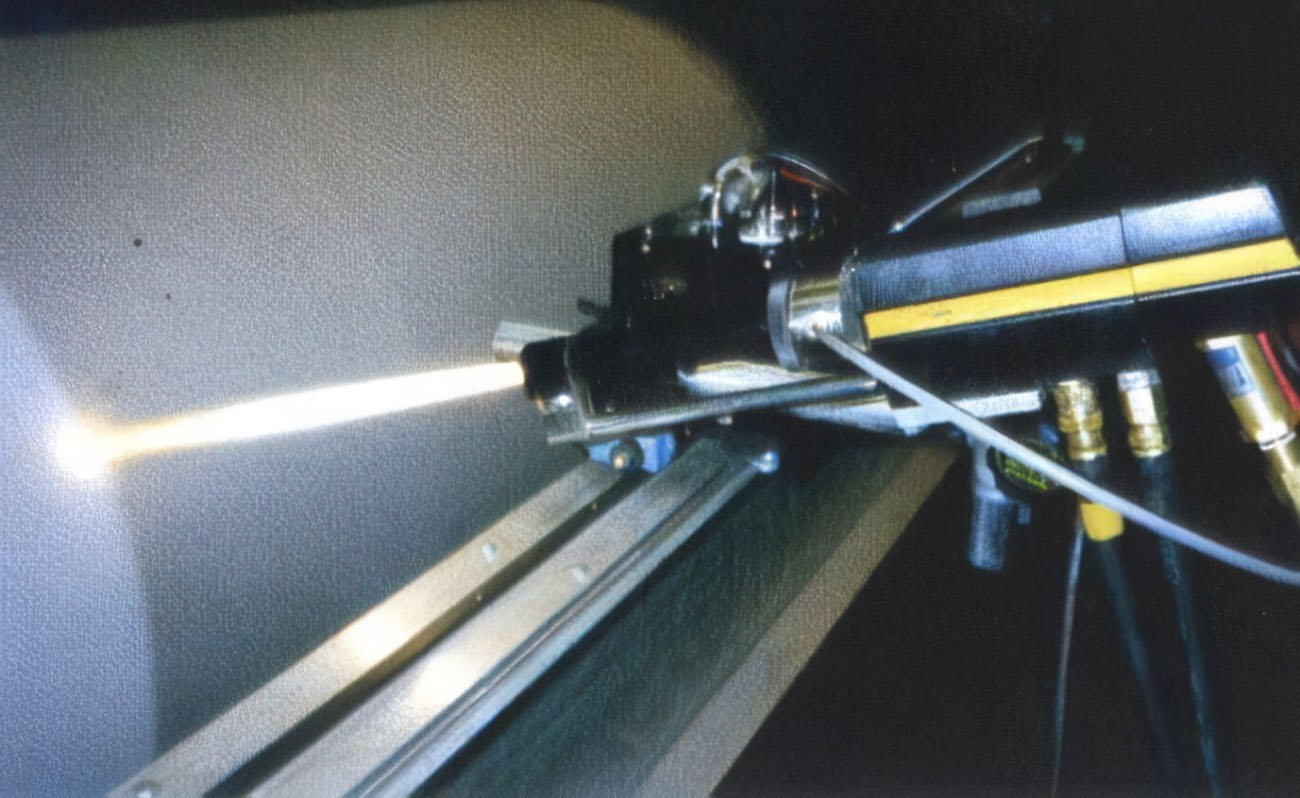

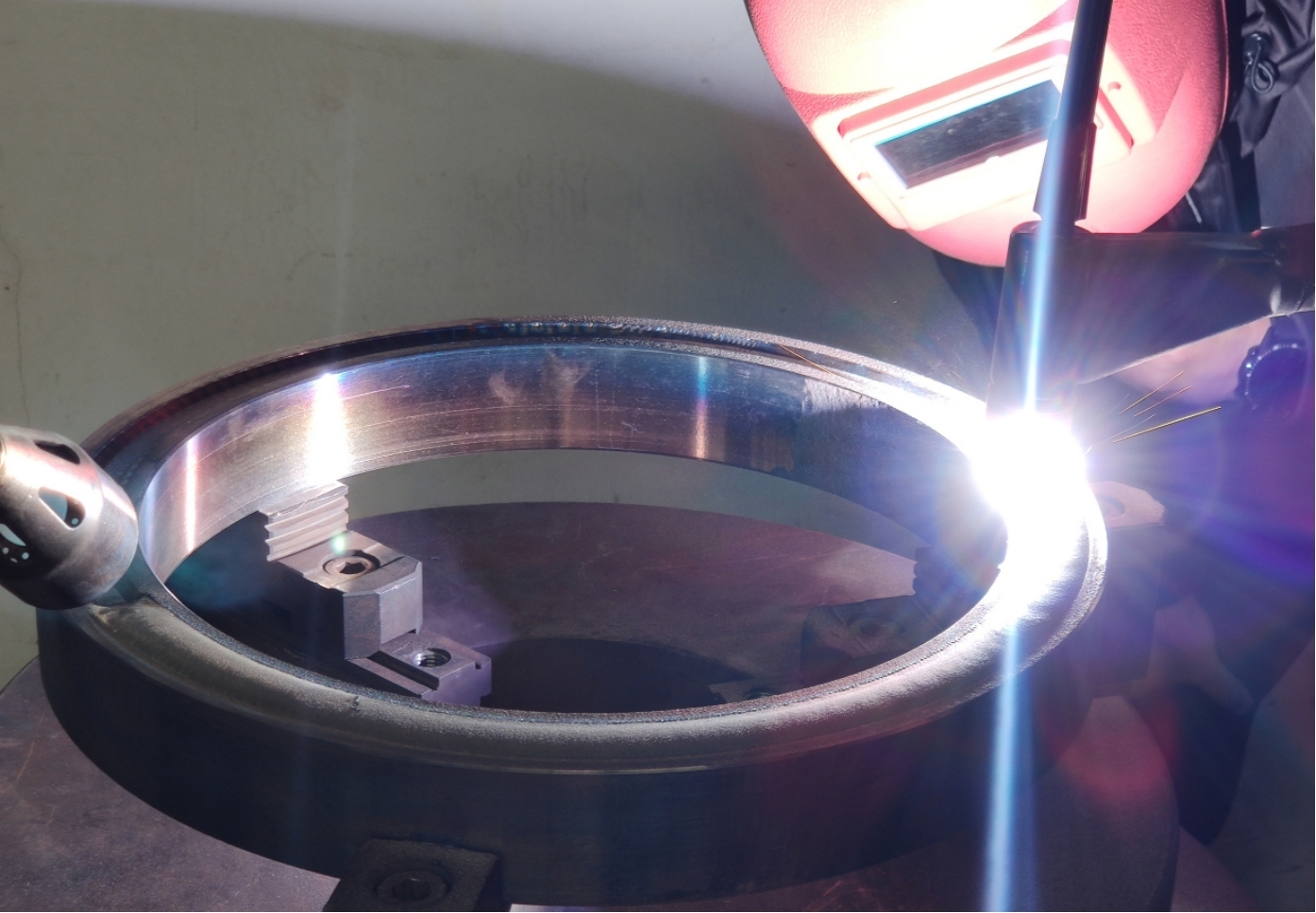

Oxyacetylene flame spray welding (welding) method

What is the most commonly used nickel-based self-fluxing alloy Ni60?

Ni60 is a high hardness (HRC 55-60) nickel-chromium-boron-silicon (NiCrBSi) self-fluxing alloy with excellent wear resistance, corrosion resistance and high temperature performance.

Primer used before plasma spraying ceramic powder

The nickel-chromium alloy primer used before plasma spraying ceramic coating is usually high-temperature alloy powder such as Ni80Cr20 or Ni70Cr30. Its main function is to enhance the bonding strength between the ceramic layer and the metal substrate and prevent the coating from cracking due to high-temperature oxidation and thermal expansion mismatch.