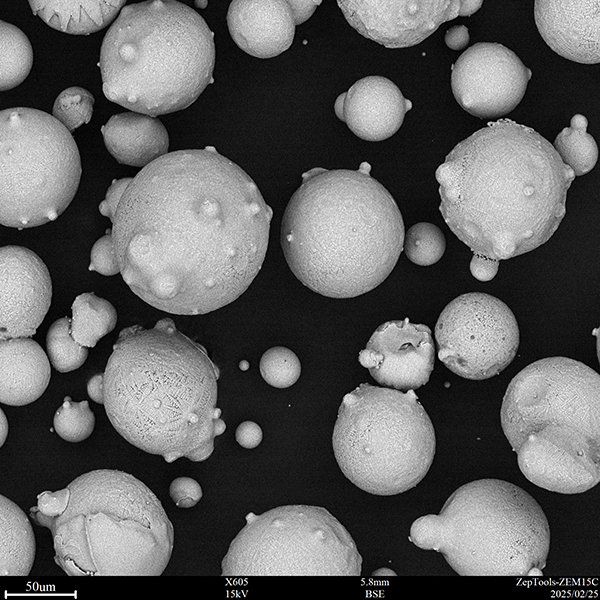

0102

Hastelloy C276 a high-performance corrosion-resistant alloy widely

Basic information

The main components of Hastelloy C276 include:

● Nickel (Ni): The content is above 57%. Nickel is a metal with excellent corrosion resistance, which can significantly improve the overall corrosion resistance of the alloy.

● Chromium (Cr): Content is 14.5-16.5%. The chromium element forms a dense oxide film on the surface of the alloy, which enhances the oxidation resistance and corrosion resistance of the alloy, allowing the welding layer to maintain good stability in an oxidizing environment.

● Molybdenum (Mo): content is 15-17%. The molybdenum element effectively improves the alloy’s resistance to corrosive ions such as chloride ions, and is especially suitable for corrosive environments containing chloride ions.

● Tungsten (W): 3.5%. Tungsten further enhances the alloy’s corrosion resistance.

● Iron (Fe): 4.5% and Cobalt (Co): 1.5%. Elements such as iron and cobalt regulate the strength of the alloy.

● The content of elements such as Carbon © and Silicon (Si) is extremely low to reduce the adverse effects on the corrosion resistance of the alloy.

This unique combination of ingredients makes Hastelloy C276 excellent in a variety of corrosive environments, especially in the chemical industry and marine engineering.

Performance characteristics

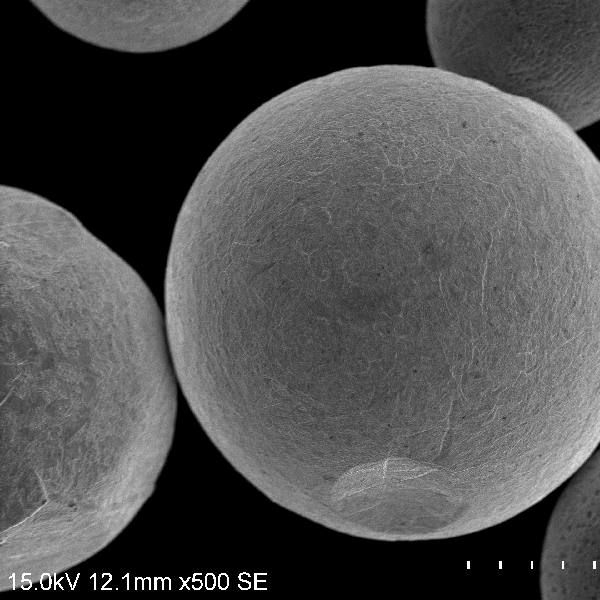

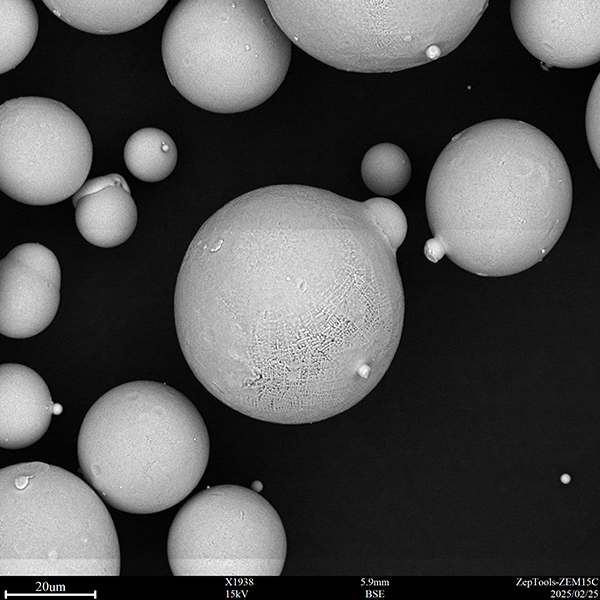

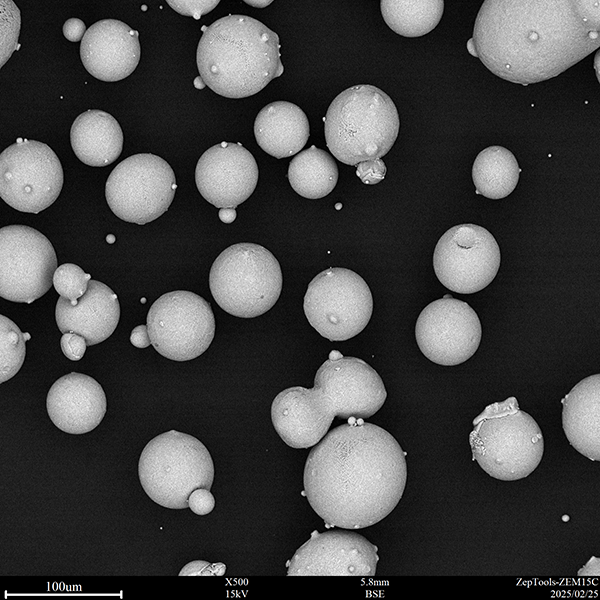

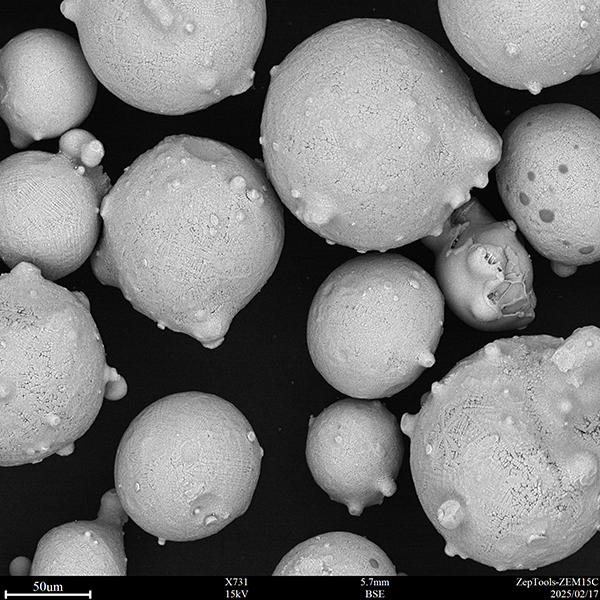

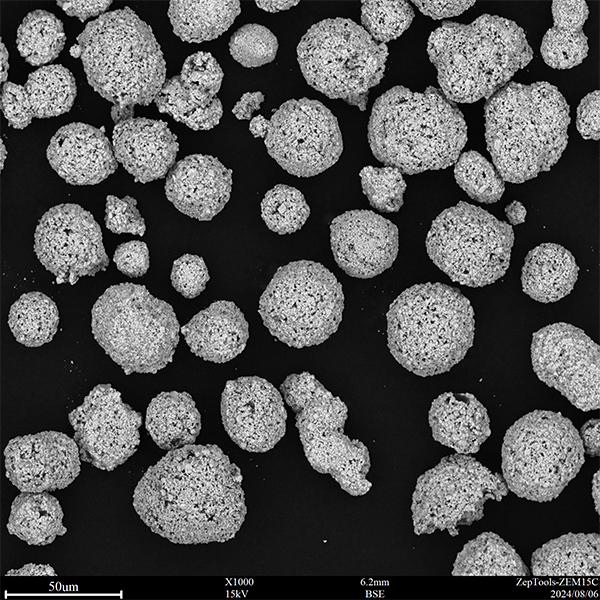

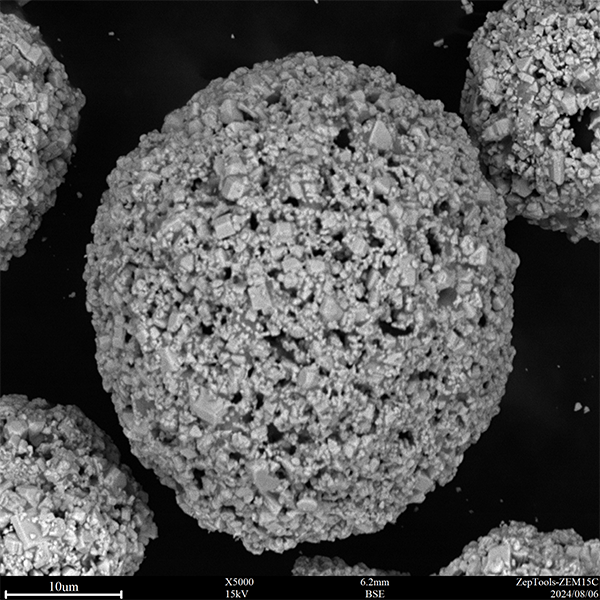

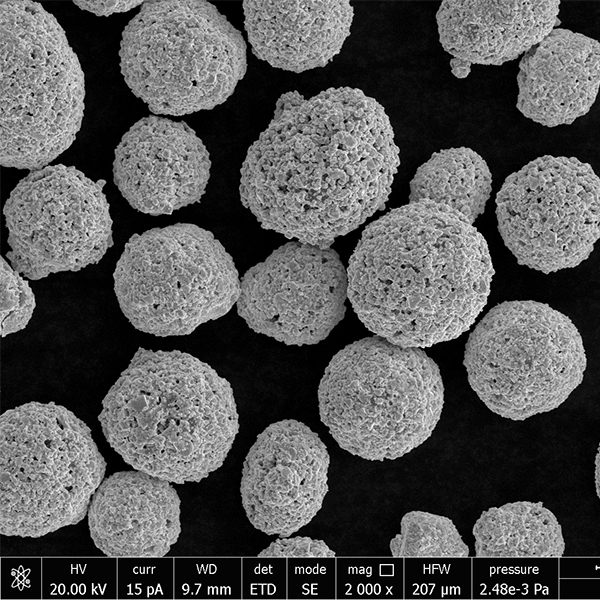

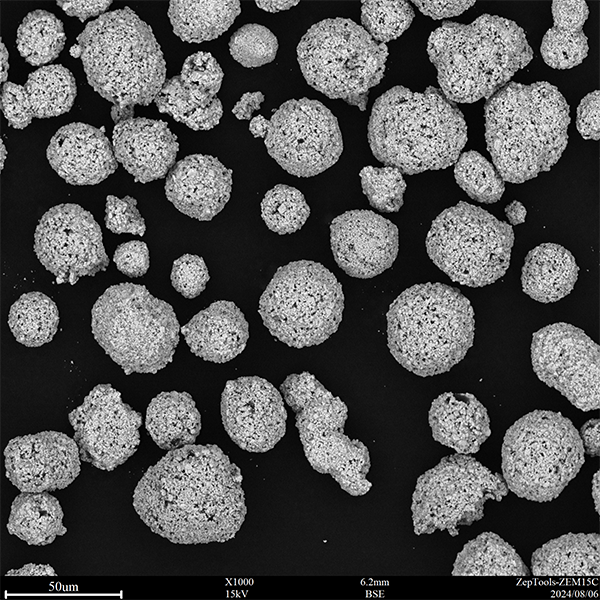

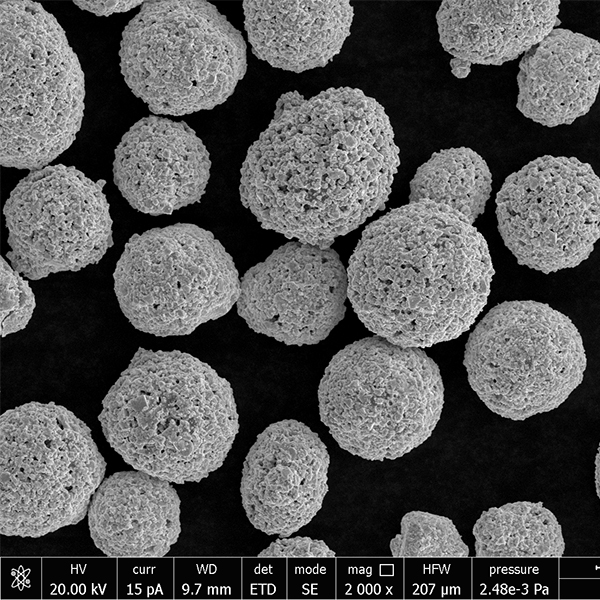

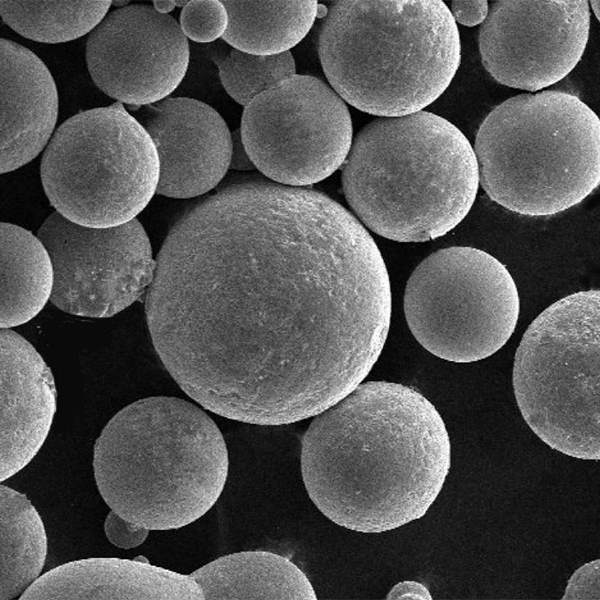

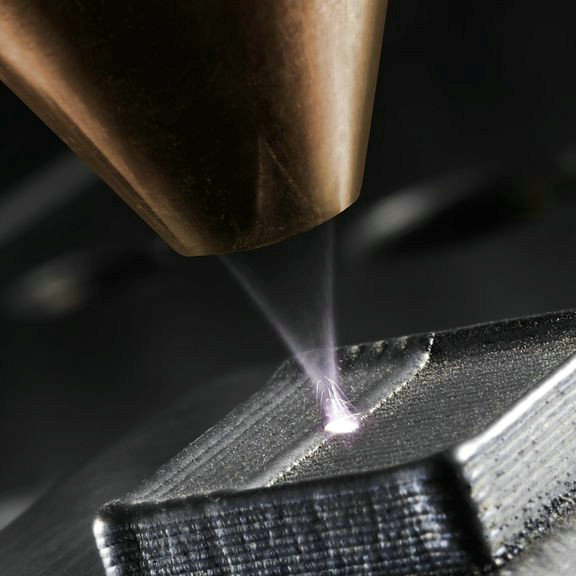

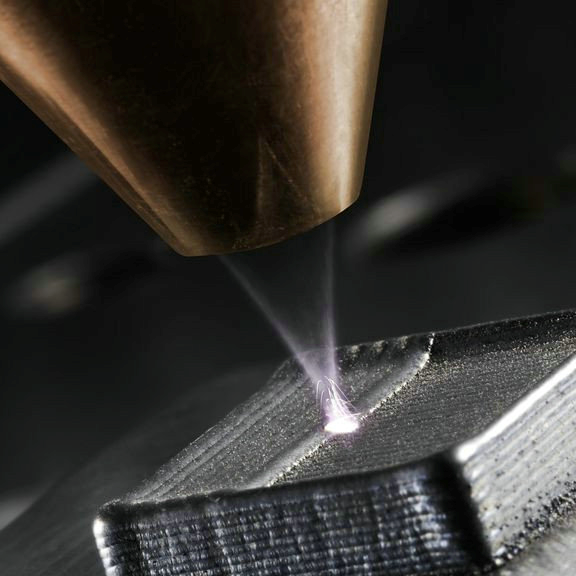

Hastelloy C276 is usually processed using advanced processes such as laser cladding, supersonic spraying or plasma spraying. Since its melting point is about 1325-1370°C, the spray welding process is not recommended. The performance characteristics of the solder layer include:

Excellent corrosion resistance: Hastelloy C276 can withstand wet chlorine, various oxidizing chlorides, chloride salt solutions, etc., and is resistant to high-concentration chloride salt solutions such as ferric chloride and chloride. Copper also exhibits significant corrosion resistance. Hastelloy C276 also performs well in sulfuric acid solutions of various concentrations, especially hot concentrated sulfuric acid solutions, and is suitable for various corrosive working conditions such as sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid and various organic acids.

Good high temperature stability: Due to its high melting point, Hastelloy C276 can be used in high temperature environments for a long time and is suitable for high temperature chemical reactions and high temperature corrosion environments.

Excellent toughness and plasticity: The metallographic structure of Hastelloy C276 is a face-centered cubic lattice structure. This structure gives the alloy good toughness and plasticity, making it adaptable to various complex processing and conditions of use.

Main application areas

The excellent properties of Hastelloy C276 make it widely used in many industries, including:

Chemical and petrochemical fields: Widely used in components and catalytic systems that come into contact with chloride-containing organic matter, such as reaction vessels, pipelines, heat exchangers and other equipment in flue gas desulfurization and chemical production.

Ocean Engineering: Suitable for equipment and structures in seawater environments, such as ocean platforms, seawater desalination devices, etc., which can resist the corrosion of seawater.

Pulp and paper industry: It can be used in equipment such as digestion and bleaching vessels. Due to its corrosion resistance and high temperature performance, it is suitable for use in harsh chemical environments.

Aerospace field: It is also used in some components that require high material corrosion resistance and high temperature performance to ensure reliability under extreme conditions.

Summarize

Hastelloy C276 has become a leader among corrosion-resistant alloys due to its excellent chemical composition and physical properties. Whether in chemical industry, petroleum, marine engineering or other highly corrosive environments, Hastelloy C276 has demonstrated excellent performance and met the high requirements for materials in modern industry. With the continuous advancement of technology, the application fields of Hastelloy C276 will be further expanded to provide reliable solutions for more industries.

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.