Co6 Cobalt-Based Alloy: High-Performance Solutions for Wear and Corrosion Resistance

Core Performance Advantages

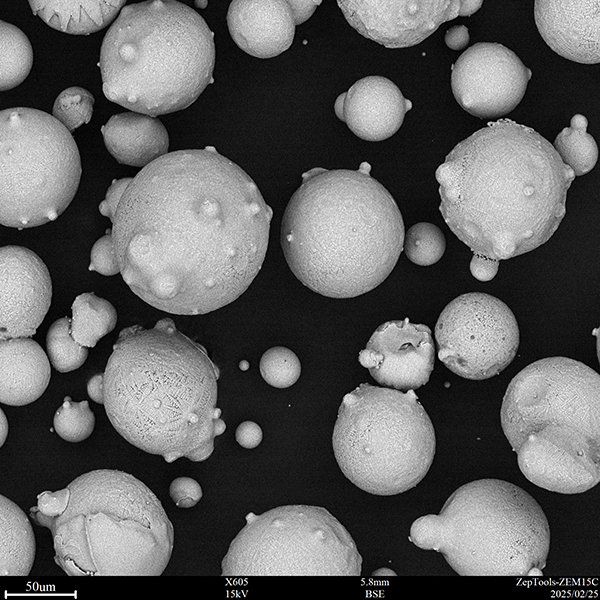

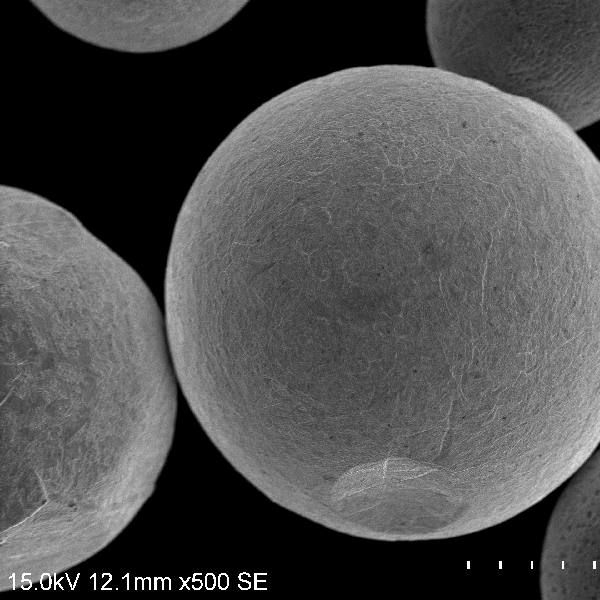

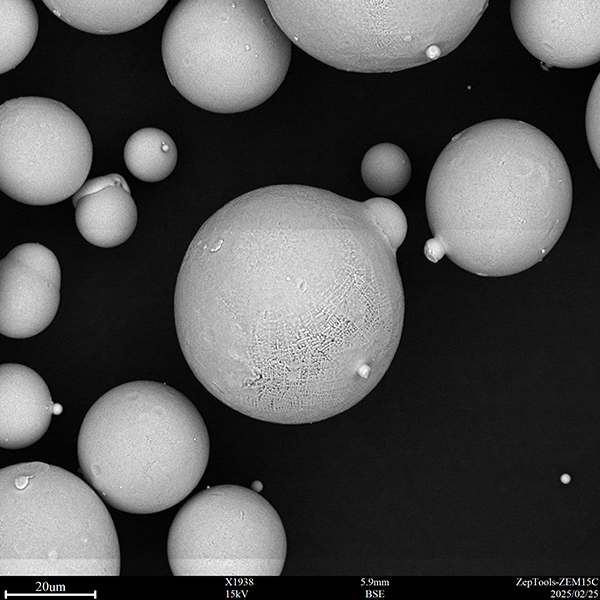

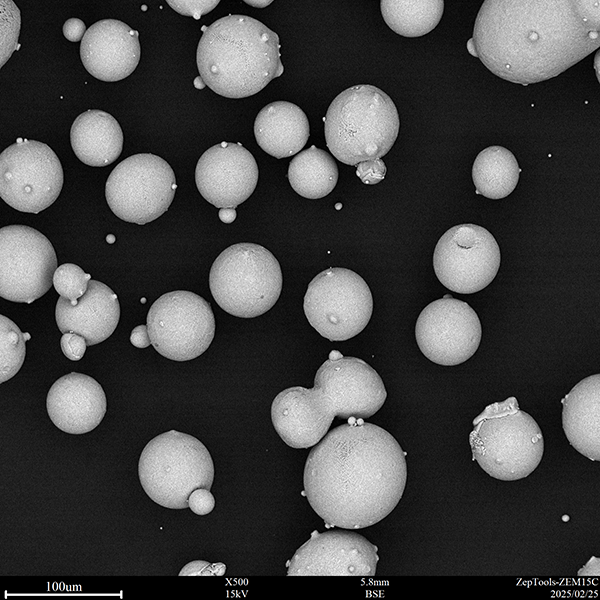

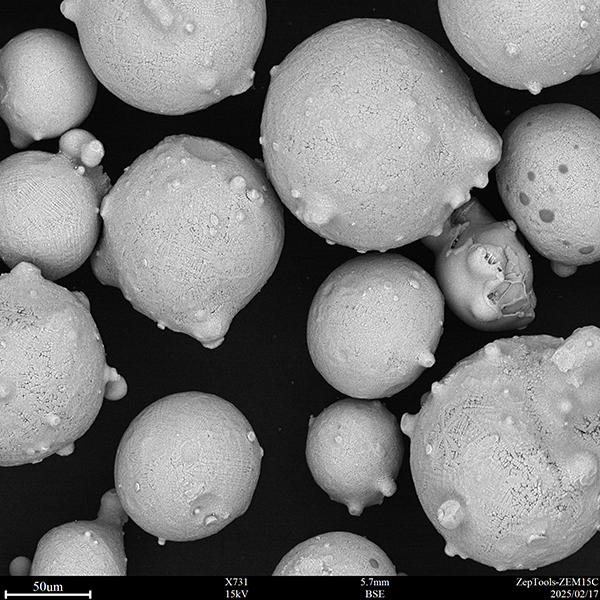

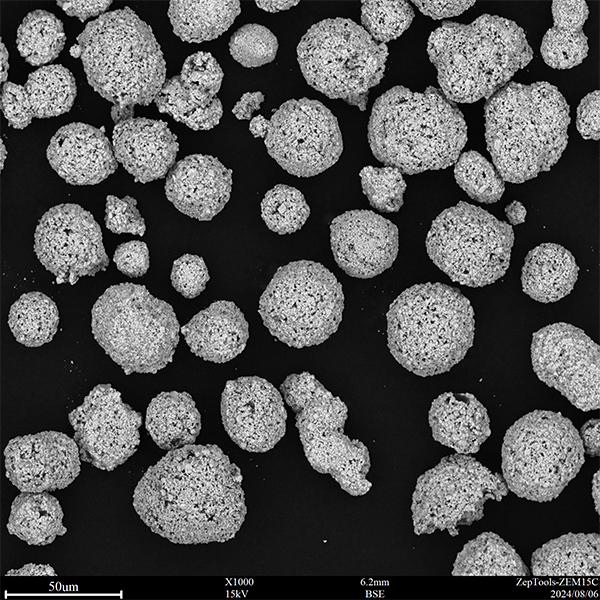

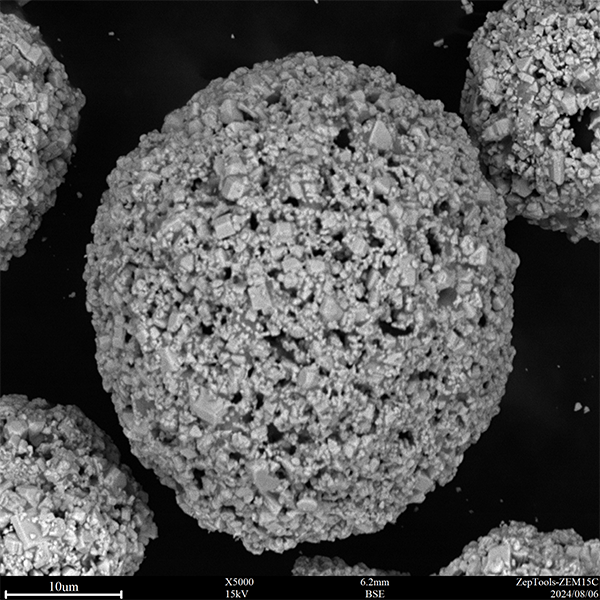

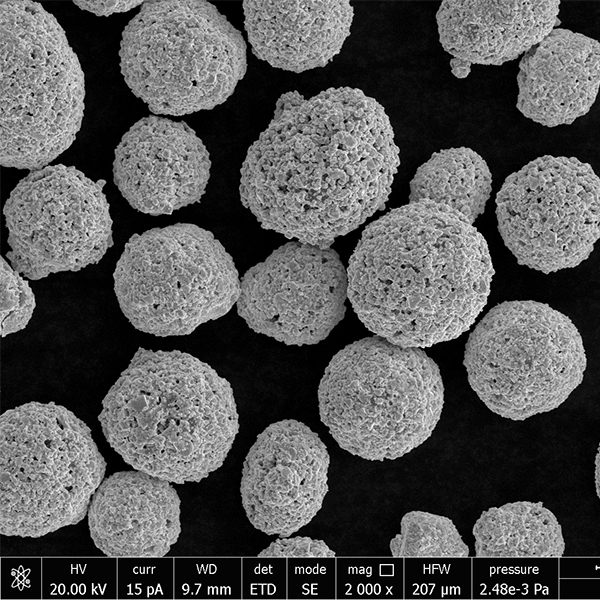

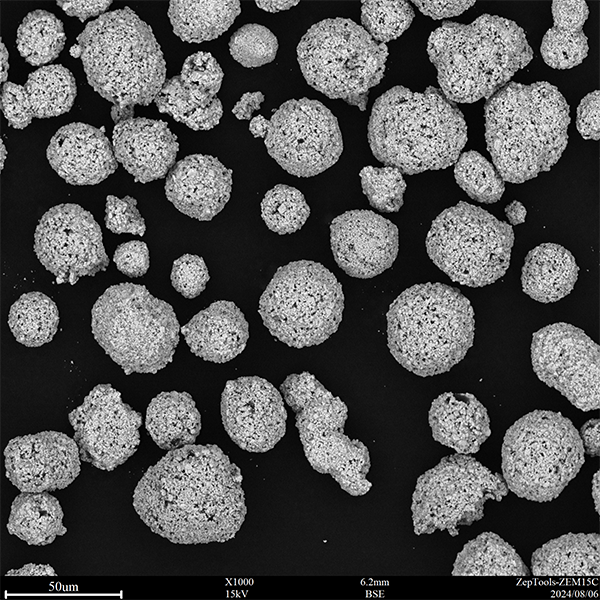

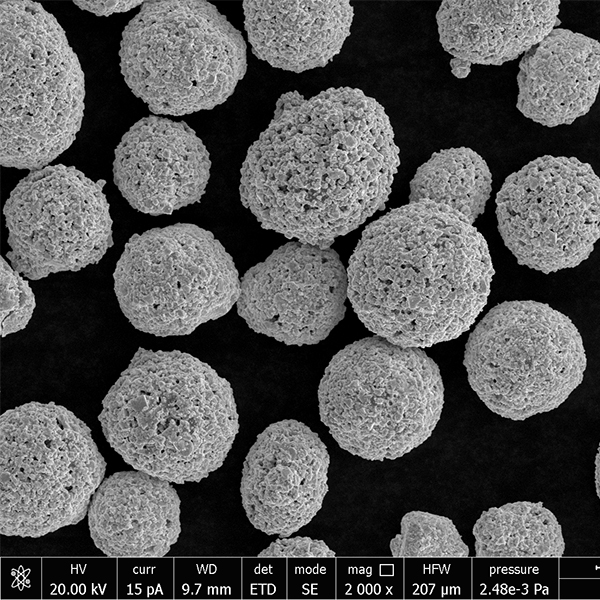

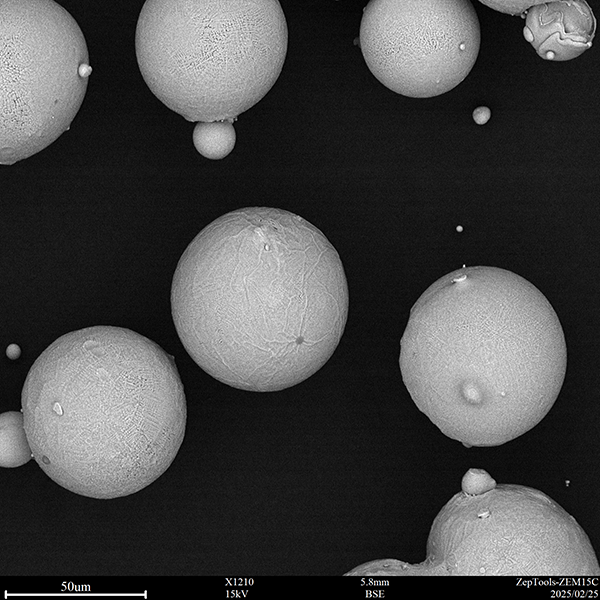

Production Process

Typical Applications

Selection Guidelines

· Low-Carbon Co6: Ideal for cavitation-prone areas (e.g., pump impellers) and moderate abrasion.

· High-Carbon Co6: Recommended for high-stress wear environments (e.g., mining gears, roll surfaces).

· Surface Treatments: Combine with thermal spraying or nitriding for enhanced hardness and wear life.

Conclusion

Co6 cobalt-based alloy combines cobalt’s high-temperature stability, chromium’s corrosion resistance, and a carbon-wrought iron system for superior wear performance. Gas atomization ensures dense, consistent microstructure, making it indispensable in extreme environments (high pressure, temperature, and corrosive media). Custom elemental adjustments or rare-earth additions (e.g., cerium) can further tailor properties for specialized applications.

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.