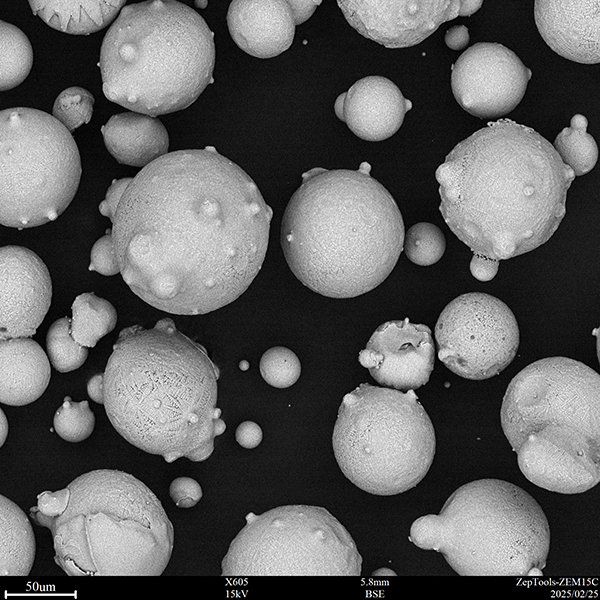

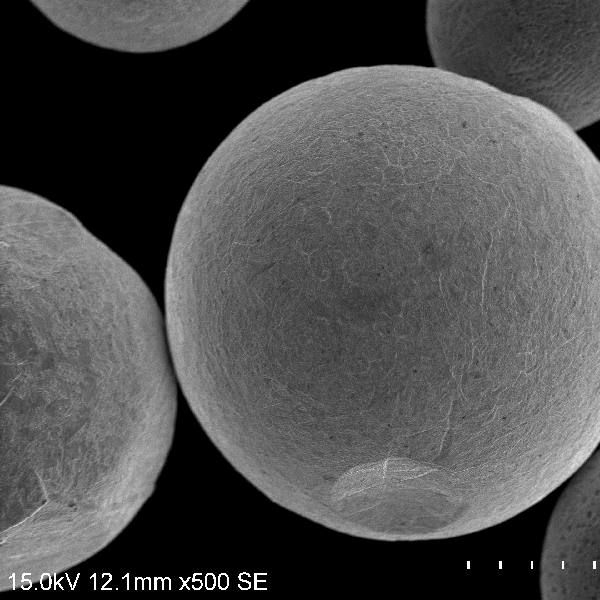

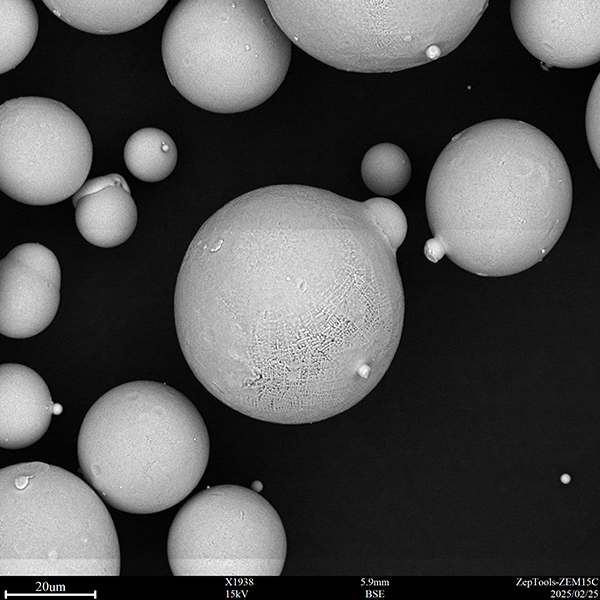

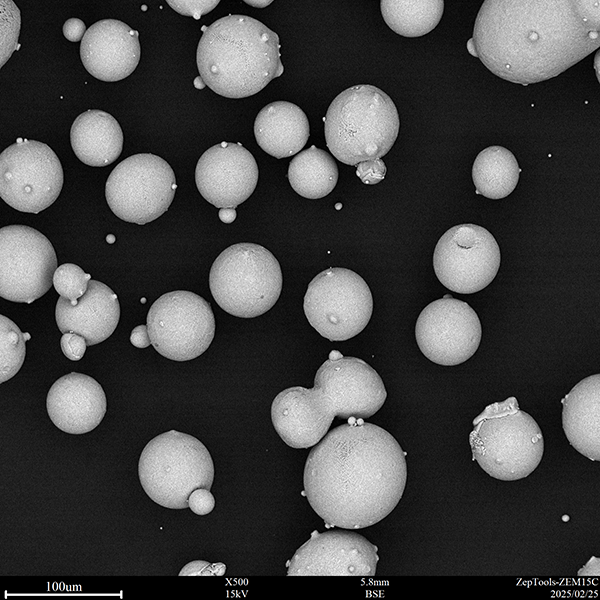

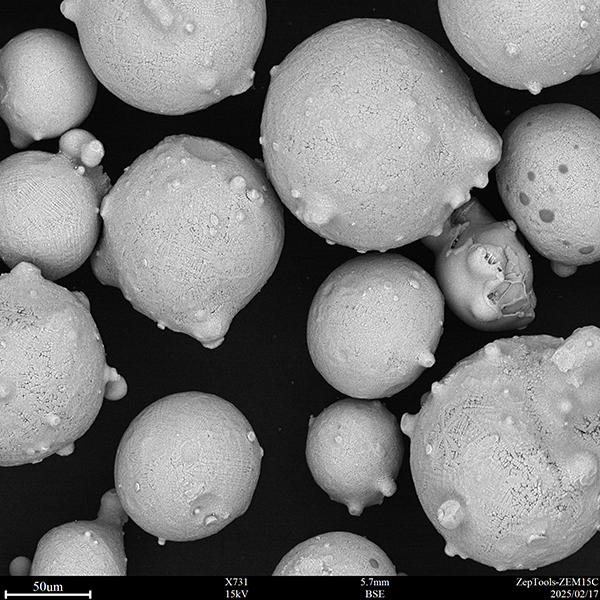

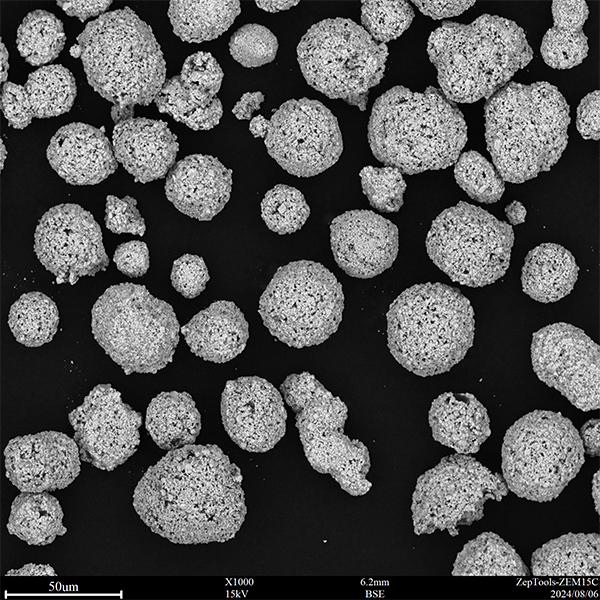

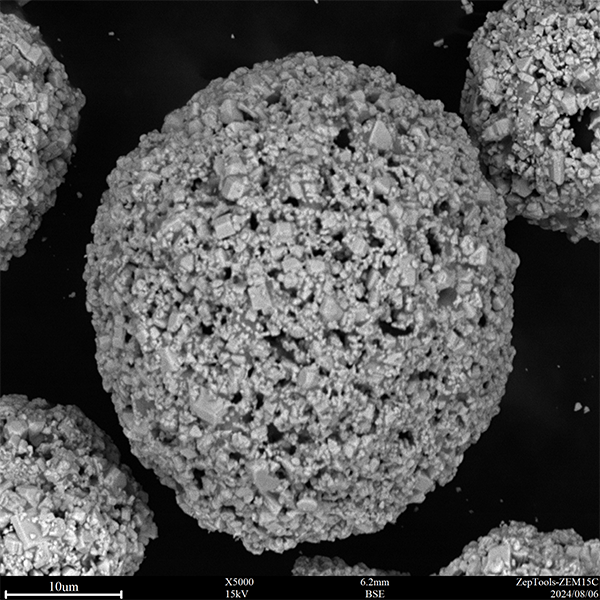

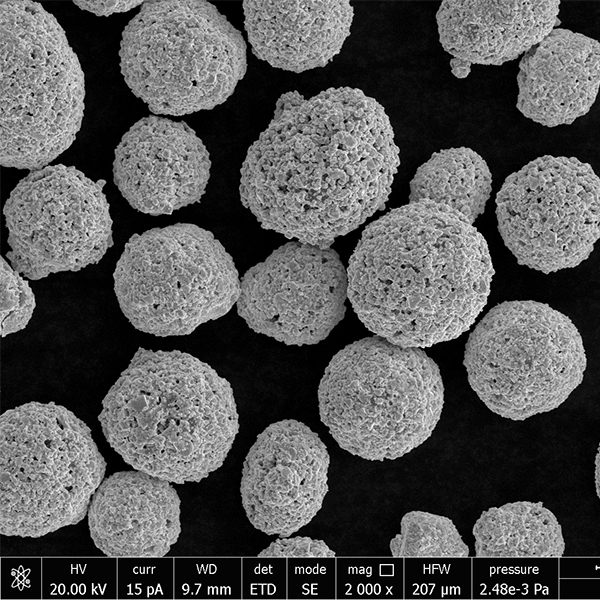

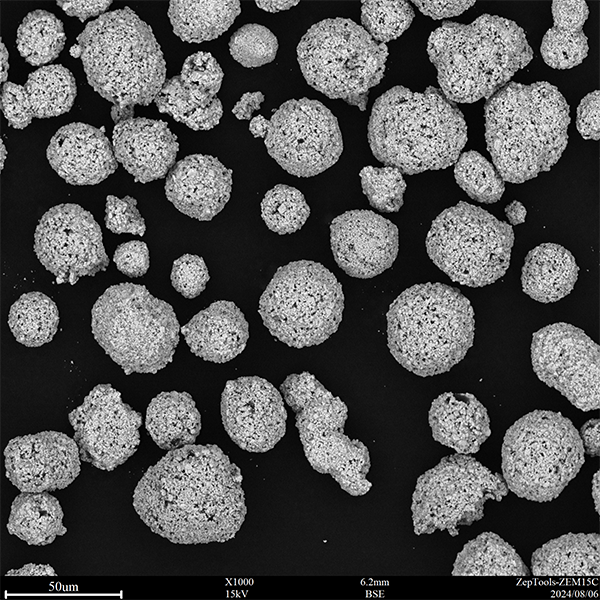

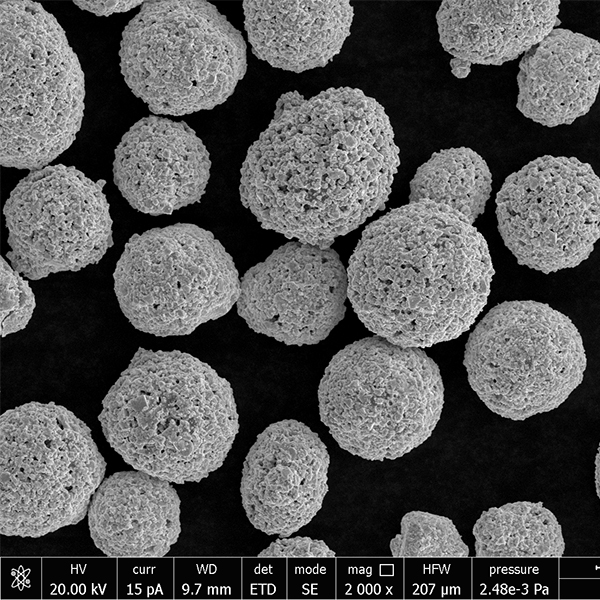

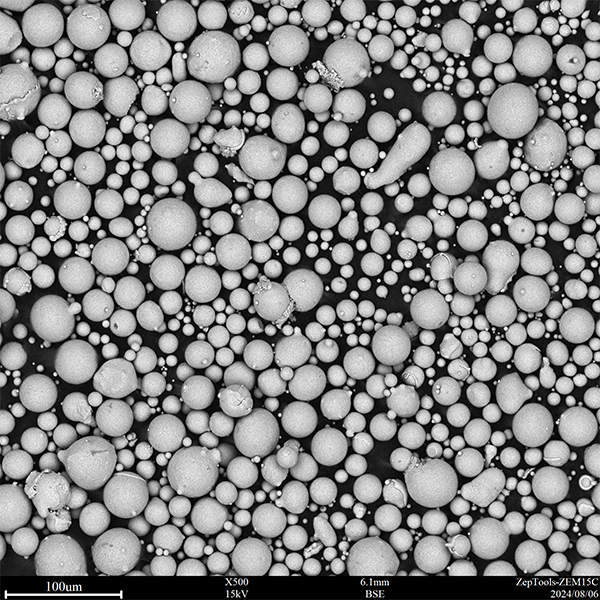

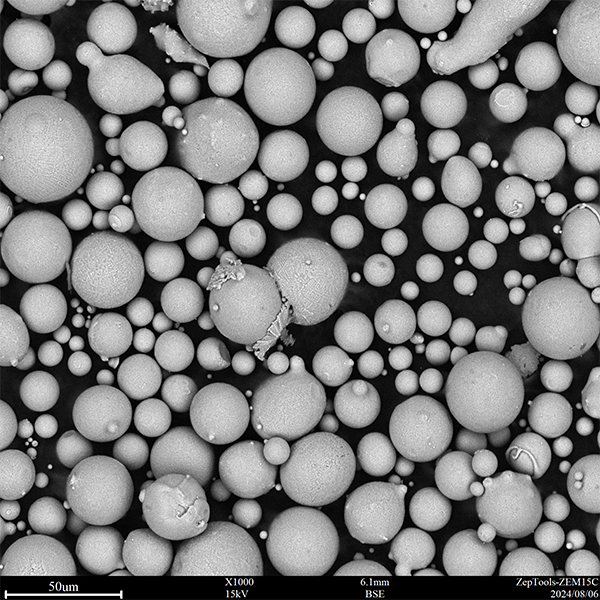

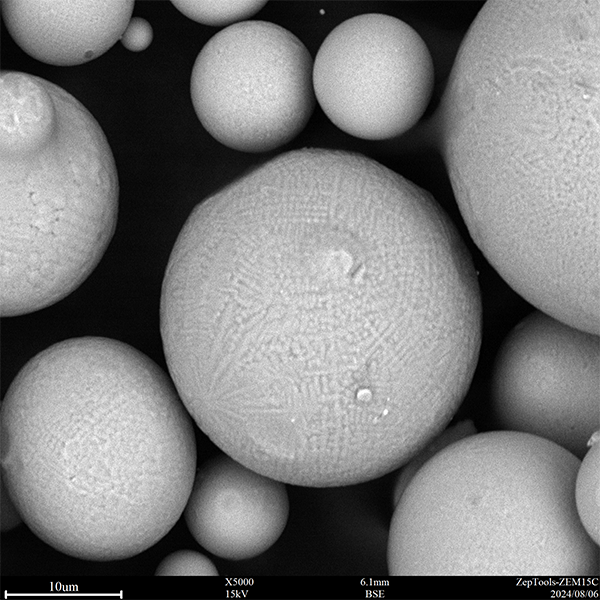

Ceramic material primer powder——DG.NiCrCoAlY, It is resistant to high-temperature oxidation and can reach an operating temperature of 980 degrees Celsius

Basic parameters

Product Performance

Application Areas

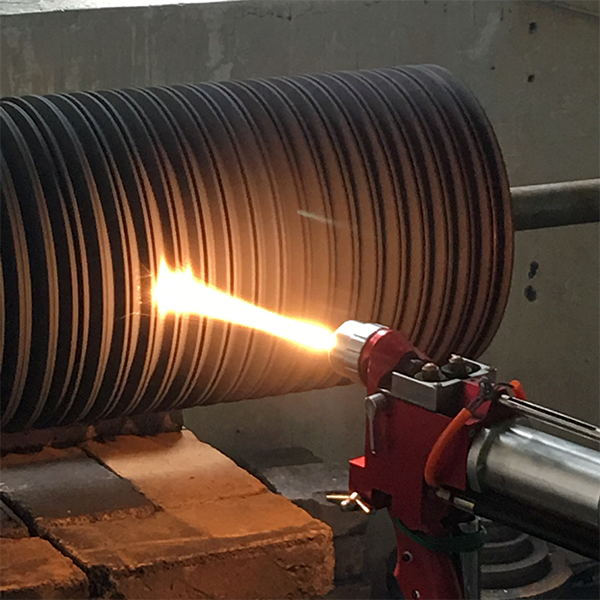

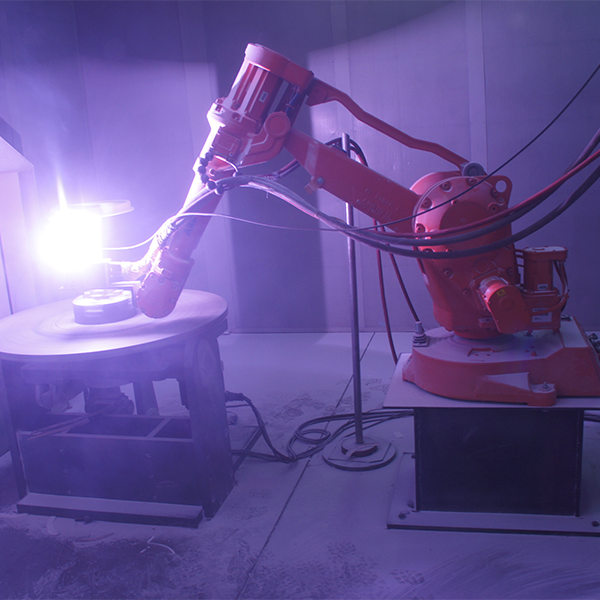

In the aerospace field, DG.NiCrCoAlY is widely used in the coating preparation of high-temperature blades. These blades are subjected to extremely high temperatures and pressures during engine operation. By spraying DG.NiCrCoAlY primer on the substrate, the high temperature resistance and oxidation resistance of the blades can be significantly improved, thereby improving the overall performance and safety of the engine.

DG.NiCrCoAlY also performs well in industrial steam turbine applications. Steam turbines face extreme temperatures and corrosive environments during operation. Using DG.NiCrCoAlY as a primer can effectively extend the service life of the coating, reduce maintenance costs, and improve equipment reliability.

Summarize

In short, as a high-performance ceramic material primer, DG.NiCrCoAlY has become an indispensable and important material in the field of thermal spraying due to its superior chemical composition, production process and application performance. Whether in aerospace or industrial steam turbine applications, it has demonstrated excellent high temperature and corrosion resistance, providing reliable protection for high-temperature workpieces. With the continuous advancement of technology, the application prospects of DG.NiCrCoAlY will be broader, providing a more solid guarantee for high-temperature protection in various industries.

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.