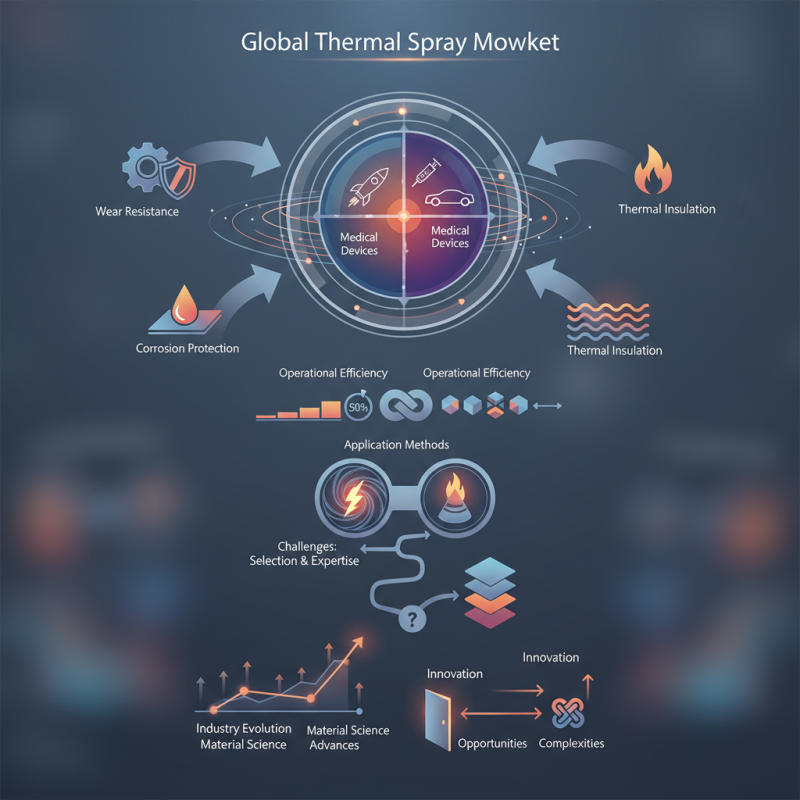

Thermal Spray Powder plays a crucial role in various industries. It is used to enhance wear resistance, corrosion protection, and thermal insulation. According to industry reports, the global thermal spray market is projected to reach $12 billion by 2025. This growth is driven by demand in aerospace, medical devices, and automotive sectors.

Utilizing Thermal Spray Powder can lead to improved operational efficiency. For example, components coated with this powder exhibit up to 50% longer life. Additionally, the application methods are diverse. They range from plasma spraying to flame spraying, each offering unique benefits. However, there are challenges. Selecting the right powder and process requires careful consideration and expertise. The decision can impact the overall performance of the finished product.

As industries evolve, the need for reliable coatings is more pressing. Advances in material science and engineering are shaping the future of Thermal Spray Powder. Each innovation presents opportunities and complexities. Addressing these will be vital for companies looking to stay competitive.

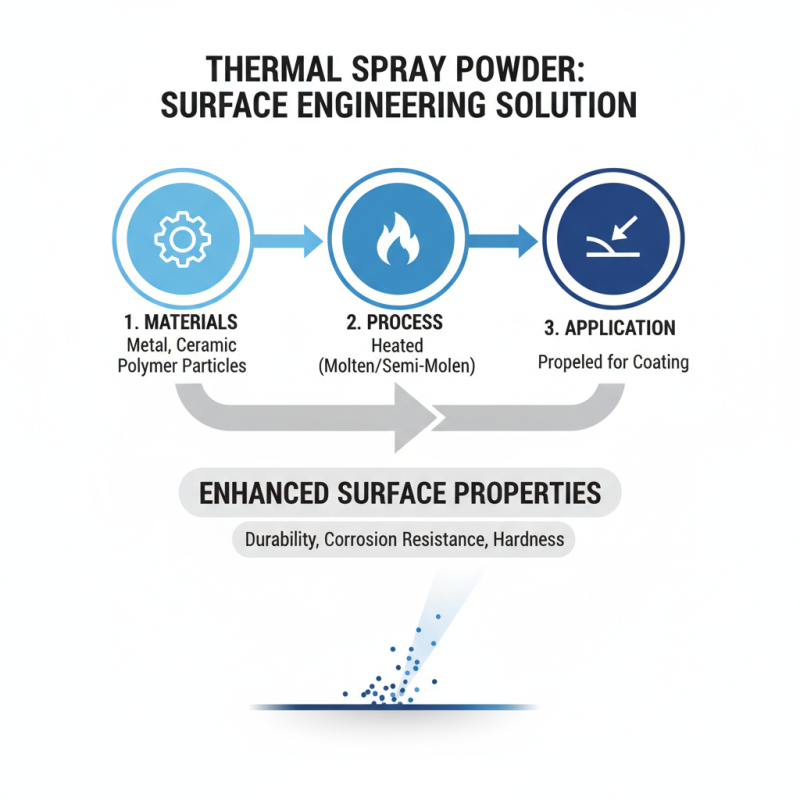

Thermal spray powder is a specialized material used in various industrial applications. These powders consist of metal, ceramic, or polymer particles. They are crucial in surface engineering. The process involves heating these particles to a molten or semi-molten state. After that, they are propelled toward a surface for coating.

According to a market report by ResearchAndMarkets, the global thermal spray market is expected to reach $11 billion by 2026. This growth is driven by rising demand in aerospace, automotive, and energy sectors. For instance, thermal spray coatings enhance wear resistance and corrosion resistance. They improve the lifespan of critical components. The coatings can be applied to parts like turbines and pumps to extend their operational life.

However, the application of thermal spray powder is not without challenges. Achieving a uniform coating thickness can be difficult. Operators must carefully monitor the process parameters to ensure quality. In some cases, imperfections may occur. These issues highlight the need for continual improvement in techniques and technologies. Despite these challenges, the effectiveness of thermal spray coatings remains widely recognized across various industries.

Thermal spray powders are integral for surface engineering. They play a fundamental role in enhancing the durability of components. Various compositions exist, which cater to diverse applications across industries.

Common types of thermal spray powders include metals, ceramics, and composites. Metal powders, often aluminum or nickel-based, are excellent for corrosion resistance. Ceramic powders such as zirconia or alumina provide exceptional thermal insulation. According to a report by Research and Markets, the market for thermal spray technology is projected to reach $15 billion by 2026. This rising demand emphasizes the significance of choosing the right powder type for specific needs.

Each powder type has unique properties that affect performance. Factors like particle size and morphology impact the coating's adhesion and microstructure. However, the selection process can be daunting. Not all powders suit every application. Testing and experimentation are essential to achieve optimal results. Defining the right parameters often requires significant iterations, leading to potential delays. Industry experts suggest a trial-and-error approach but remain skeptical about its efficiency. Finding balance is a challenge.

The thermal spray process is a fascinating technology widely used in various industries. It involves applying a coating to a substrate material. This is achieved by heating powder or wire to a molten or semi-molten state. The molten material is then propelled onto the surface of the workpiece. Techniques include plasma spraying, wire arc spraying, and flame spraying.

Choosing the right equipment is crucial. Plasma spray guns can reach high temperatures and are perfect for ceramics. Wire arc systems are more suitable for metals, offering high feed rates. Each method has its advantages but also drawbacks. Reliability can vary; users need to understand the limitations of each technique.

Tips: Before starting your project, ensure your surface is clean. Contaminants can affect adhesion. Test different powders for the desired coating properties. Experimentation can lead to surprising results. Each application deserves careful consideration to avoid costly mistakes. Always observe safety protocols when handling equipment and materials.

Thermal spray powders are essential in various industries for surface protection and enhancements. They provide a sturdy layer that increases wear resistance. Industries like aerospace utilize these coatings for engine components. The coatings can withstand extreme temperatures and corrosive environments.

In automotive manufacturing, thermal spray powders improve the lifespan of components. They can be used on engine parts, transmissions, and other critical components. The goal is to extend service life and reduce maintenance costs. Additionally, the energy sector adopts these powders to protect equipment from wear and thermal stress. This is crucial in maintaining efficiency and operational reliability.

However, the application process can be tricky. Proper technique is vital to achieving optimal results. If the surface preparation is not done correctly, it can lead to adhesion issues. This can undermine the benefits of the powders. Reflecting on these challenges helps improve the overall process.

Thermal spray technology offers remarkable advantages. It enhances surface properties significantly. This process can improve materials' wear resistance and corrosion protection. Industries often rely on these benefits for components in harsh environments. The ability to apply coatings rapidly is also a key advantage. It reduces downtime in manufacturing and extends the lifespan of parts.

However, challenges exist. One major issue is the consistency of coating quality. Variations in application can lead to defects. Proper equipment setup is crucial to minimize these inconsistencies. Operators must be well-trained to ensure optimal results. Environmental concerns also arise from the materials used in thermal spray processes. Emission control is essential to mitigate potential impacts.

Investment in thermal spray technology can be substantial. This might deter some companies from adopting it. Evaluating the cost-effectiveness is necessary for informed decisions. Despite the hurdles, the potential benefits are too significant to overlook. A careful assessment can lead to successful applications in diverse fields.