In the realm of modern industries, Spray Powders have emerged as a vital component. These fine particles are pivotal for various applications, including coatings, manufacturing, and food processing. Their ability to enhance product quality and performance is unmatched. For instance, in automotive industries, Spray Powders are used for durable coatings that withstand harsh conditions.

However, not all processes are perfect. Misapplication can lead to waste and inefficiency. Industries need to reflect on their techniques. Adjustments are often necessary to optimize results with Spray Powders. Professionals must continuously learn and adapt.

Moreover, the rise of sustainable practices has influenced Spray Powders' usage. Industries are seeking eco-friendly options. The challenge is finding the right balance between performance and sustainability. As techniques evolve, the potential for innovation remains high. This underscores the importance of understanding Spray Powders in today's competitive landscape.

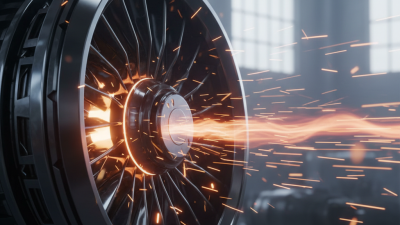

Spray powders are fine particles dispersed in a carrier gas. They are vital in various industries, including automotive and aerospace. These powders ensure uniform coating on surfaces. This property is crucial for applications such as thermal spraying.

Key characteristics of spray powders include particle size and morphology. Smaller particles provide better adhesion to surfaces. However, managing these tiny particles can be challenging. Their behavior in the spray process varies based on size and shape. Consistency is hard to achieve in large production runs.

Another important aspect is the material composition. Different industries require specific alloy combinations. Choosing the right material affects performance and durability. But it's not always straightforward. Sometimes, unexpected interactions occur during processing. These can lead to flaws in the final product. Families of powders can behave unpredictably, making quality control essential.

Spray powders have become pivotal in various industries, driving innovation and efficiency. In manufacturing, they offer precise control over particle size and distribution. This ability is crucial for applications like additive manufacturing, where quality directly impacts component performance. According to a recent report by MarketsandMarkets, the global market for spray powders is expected to grow by over 6% annually, reflecting their importance across sectors.

In the food and beverage industry, spray powders enhance product texture and longevity. Companies utilize them to create instant mixes and powdered beverages. A study by Future Market Insights notes that the powdered food market is projected to reach $100 billion by 2026. This growth signals a shift towards convenience in consumer preferences, challenging companies to adapt swiftly.

However, the adoption of spray powders comes with challenges. Not all manufacturers have mastered the technology, leading to inconsistencies in quality and performance. The complexity of the spray drying process can be daunting. Many companies must refine their techniques to meet industry standards. This ongoing trial and error highlights the need for continuous improvement and innovation within the sector.

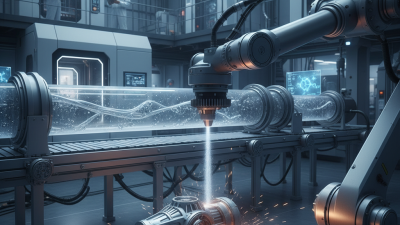

In modern manufacturing, spray powders play a vital role. These finely dispersed particles enhance production efficiency. Industries use them for coating, additive manufacturing, and surface treatment. The application process is quick and versatile. This saves time and reduces costs.

Using spray powders brings several advantages. They provide uniform coverage on surfaces. This improves the quality of the final product. The powders can be tailored to specific applications. This versatility allows manufacturers to achieve unique properties. They can create lightweight composites or strong coatings.

Despite their benefits, challenges remain. Not every spray nozzle works well with every powder. Proper testing is essential for optimal results. Adjusting the spray parameters can be complex. However, the potential for innovation keeps industries exploring new possibilities.

| Dimension | Description | Examples |

|---|---|---|

| Material Composition | Spray powders are typically made from metal, ceramic, or polymer materials that provide desired properties. | Aluminum alloy powders, zirconia powders, nylon powders. |

| Applications | Used in various manufacturing processes including coating, 3D printing, and thermal spray processes. | Aerospace components, medical devices, automotive parts. |

| Advantages | Provide enhanced surface properties, improved adhesion, and reduced waste in manufacturing. | Increased durability, corrosion resistance, and better thermal properties. |

| Industry Impact | Spray powders revolutionize traditional manufacturing by enabling more complex geometries and faster production rates. | Additive manufacturing, high-performance coatings, efficient repair processes. |

| Future Trends | Growing use of advanced materials and environmentally friendly powders to meet sustainability goals. | Bio-based polymers, recycled metal powders. |

Spray powders play a crucial role in various modern industries. They are widely used in applications such as additive manufacturing, coatings, and pharmaceuticals. In additive manufacturing, powder materials are key to building complex structures. With precise control, these powders create detailed layers. Yet, achieving consistent quality is a challenge. Variations can impact the final product.

In the coating industry, spray powders improve surface properties. These powders are applied to enhance durability, corrosion resistance, or aesthetics. However, the application process can be inconsistent. Achieving uniform coverage is not always easy. It raises questions about the efficiency and effectiveness of the techniques used.

Pharmaceuticals also benefit from spray powders. They are used in drug formulation and delivery systems. These powders enable precise dosages and improved solubility. Controlling particle size is vital but difficult. Inconsistent results can lead to issues. It’s essential to advance methods for better quality control.

Spray powders are rapidly transforming industries. In sectors like coatings, pharmaceuticals, and agriculture, their utility is becoming clear. Innovative applications are emerging frequently. For instance, in coatings, companies are discovering new textures and durability through spray powders. This creates vivid finishes that stand out.

Future trends indicate a move towards sustainable materials. There is increasing pressure to reduce waste. Spray powders can help achieve that goal. Their precision allows for efficient use of raw materials. Additionally, advancements in formulation technology are paving the way for cleaner processes. However, challenges remain. Working with new materials often leads to inconsistencies in performance.

Exploring possibilities in the realm of customization is another trend. Industries might begin to tailor spray powders for specific applications. This could enhance product characteristics, but it may also complicate production. Balancing innovation with reliability is crucial. The path forward is not without hurdles, yet the potential is undeniable.