Nickel Powder Coating has emerged as a revolutionary technique in surface finishing, significantly enhancing the durability and performance of various materials. This method involves applying a fine layer of nickel powder to substrates, creating a protective barrier that not only improves corrosion resistance but also enhances the aesthetic appeal of the finished product. The unique properties of nickel, such as its hardness and resistance to wear, make Nickel Powder Coating an ideal choice for industries aiming to increase the longevity of their components.

In today’s competitive landscape, where product performance and lifespan are paramount, understanding the effective utilization of Nickel Powder Coating becomes essential. This coating process not only protects against environmental factors but also withstands mechanical stress, making it suitable for a wide range of applications, from automotive to aerospace. By adopting best practices in the application and curing processes, manufacturers can achieve optimal results, ensuring their products stand the test of time while also meeting stringent industry standards.

As we delve deeper into the methods and advantages of Nickel Powder Coating, it becomes clear that this technique is not just an enhancement but rather a strategic choice for businesses dedicated to quality and durability. By leveraging the full potential of this innovative coating, companies can enhance their offerings and gain a competitive edge in the marketplace.

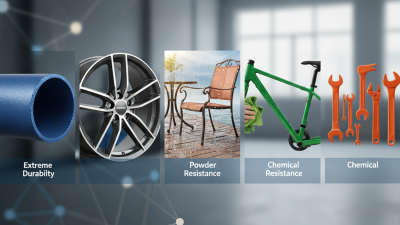

Nickel powder coating is a versatile finishing technique that offers numerous benefits for various applications. One of its primary advantages is its ability to enhance corrosion resistance significantly. This is particularly crucial in industries where components are regularly exposed to harsh environmental conditions, such as marine, automotive, and aerospace sectors. The coating acts as a protective barrier, preventing moisture, chemicals, and other corrosive elements from compromising the substrate material. Additionally, nickel powder coatings can provide an aesthetically pleasing finish that ranges from a matte to a glossy appearance, allowing for customization in design without sacrificing durability.

Another essential application of nickel powder coating lies in its wear resistance properties. The coating can withstand heavy wear and tear, making it ideal for components that experience friction and contact with other surfaces. Industries such as manufacturing and heavy machinery benefit from this characteristic, as it extends the lifespan of critical parts and reduces the frequency of maintenance and replacement. Furthermore, nickel powder can be applied in various thicknesses, providing flexibility in achieving the desired level of protection. With advances in powder coating technology, the versatility and performance of nickel coatings continue to improve, making them an increasingly popular choice across multiple sectors.

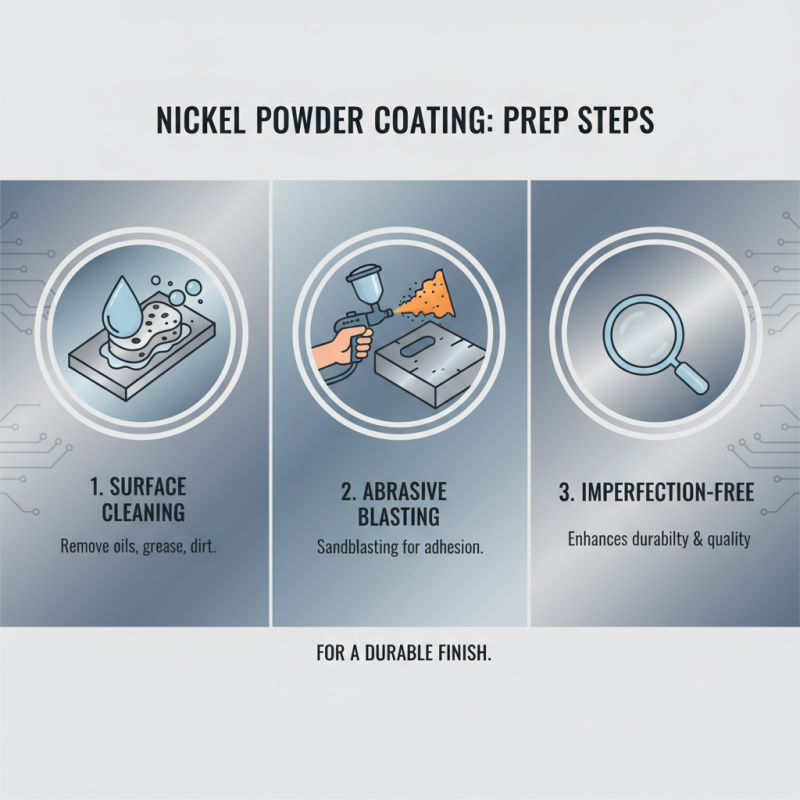

The preparation steps for nickel powder coating are crucial to achieving a durable and high-quality finish. First and foremost, surface cleaning is imperative. This involves removing any contaminants such as oils, grease, dirt, and rust from the substrate. A combination of chemical cleaners and abrasive methods, like sandblasting, will ensure that the surface is adequately prepared for the coating. Ensuring that the surface is free of imperfections will enhance adhesion and improve the overall durability of the coating.

Following the cleaning process, the next step is to ensure proper surface profiling. This can be achieved by lightly abrading the substrate to create a rough texture, which facilitates better mechanical bonding of the nickel powder. It is also essential to thoroughly dry the surface after cleaning and profiling. Moisture can compromise the coating's integrity and lead to issues like peeling or blistering. Once the surface is prepared, it’s recommended to apply a suitable primer that enhances adhesion and corrosion resistance. This primer should be compatible with the nickel powder coating to ensure optimal performance and longevity of the finish.

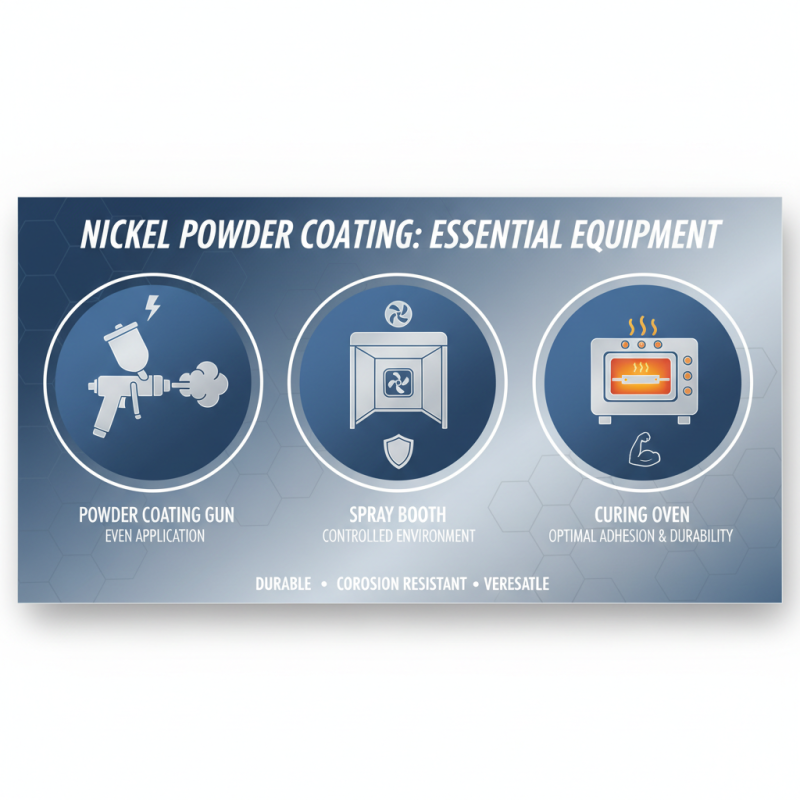

Nickel powder coating has gained popularity in various industries due to its excellent durability and resistance to corrosion. To effectively apply nickel powder coating, certain essential equipment and materials are required. The main components of the application setup include a powder coating gun, a spray booth, and curing ovens. A quality powder coating gun ensures an even and consistent application, while spray booths facilitate a controlled environment free from contaminants. Meanwhile, curing ovens are critical in achieving optimal adhesion and durability, as they allow for the proper heating of the coated surface.

For optimal results, it is important to select high-quality nickel powder that meets industry standards. Reports indicate that coatings incorporating nickel exhibit superior properties, including enhanced wear resistance and thermal stability. According to the International Journal of Coating Technology, nickel-coated surfaces can offer over 30% more resilience compared to traditional coatings in abrasive environments. Using the right substrate preparation techniques, such as sandblasting or chemical cleaning, will also significantly improve coating performance.

**Tips:** Ensure your equipment is properly calibrated for the specific nickel powder being used to avoid inconsistencies in texture or finish. Additionally, maintaining an appropriate environmental temperature in the spray booth can help in achieving better coating quality and adhesion. Regular maintenance of the curing oven is crucial to ensure consistent temperature distribution to maximize the benefits of the nickel powder coating.

Applying nickel powder coating can significantly enhance the durability of various surfaces. To achieve optimal results, it is crucial to adhere to effective application techniques. First, surface preparation is a fundamental step; thorough cleaning and degreasing of the substrate are necessary to ensure strong adhesion. According to a report from the Coating Society, surfaces that are inadequately prepared can lead to adhesion failures in up to 30% of cases. Applying a suitable primer can further improve coating performance, providing an additional layer of adhesion and corrosion resistance.

The application process itself can greatly influence the quality of the nickel powder coating. Employing an electrostatic spray application method is recommended, as this technique allows for even distribution and thorough coverage while minimizing waste. Data from industry studies indicate that this method can increase transfer efficiency by up to 90%, compared to traditional spray techniques. Additionally, controlling the curing temperature and time is vital; nickel coatings typically require a curing temperature of 180°C for optimal hardness and durability. Proper monitoring during this phase can ensure that the coating achieves the desired properties, providing long-lasting protection against wear, corrosion, and environmental degradation.

Post-Application Maintenance for Enhanced Durability

To ensure the longevity of nickel powder coatings, proper post-application maintenance is essential. According to the Coatings Research Institute, coatings that undergo routine inspections and maintenance can improve their lifespan by up to 30%. This includes regular cleaning to remove contaminants that may compromise the coating's integrity. High-pressure washing with non-abrasive methods is often recommended to keep surfaces clear without damaging the finish. Implementing a maintenance schedule can help identify potential issues early on, preserving the durability that nickel powder coatings are known for.

In addition to cleaning practices, periodic touch-ups can significantly impact the effectiveness of a nickel powder coating. Experts suggest that addressing minor scratches or abrasions promptly can prevent further deterioration. A study by the Society for Protective Coatings indicated that touching up damaged areas within three months of occurrence can restore up to 95% of the original coating’s protective properties. Moreover, using compatible touch-up materials ensures that the repaired areas bond well with the existing coating, reducing the likelihood of delamination and enhancing overall durability. By incorporating these maintenance strategies, users can maximize the performance and lifespan of nickel powder coatings, ultimately leading to more sustainable practices in surface protection.