010203

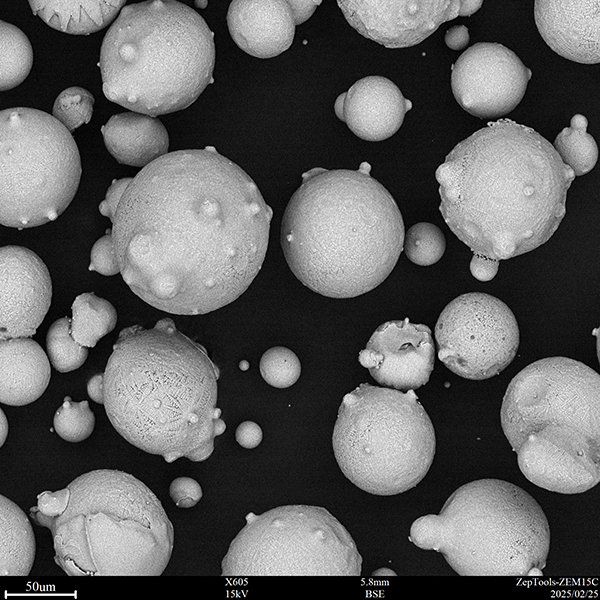

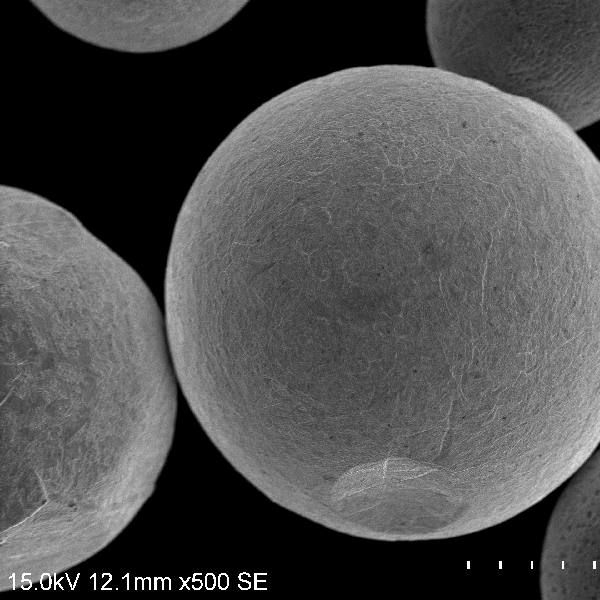

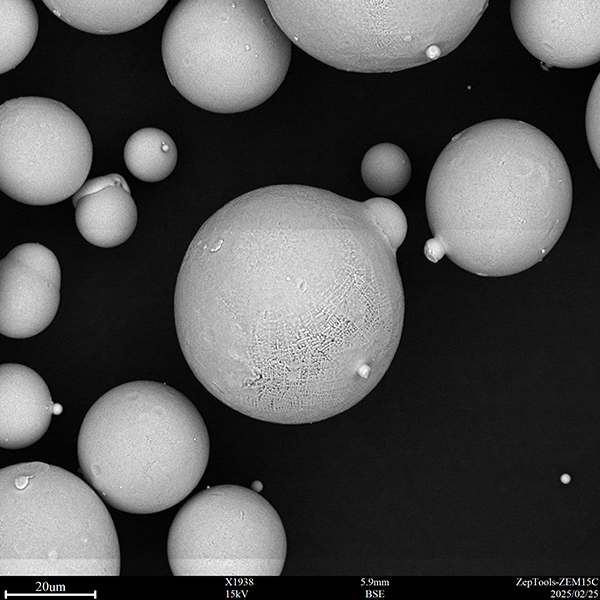

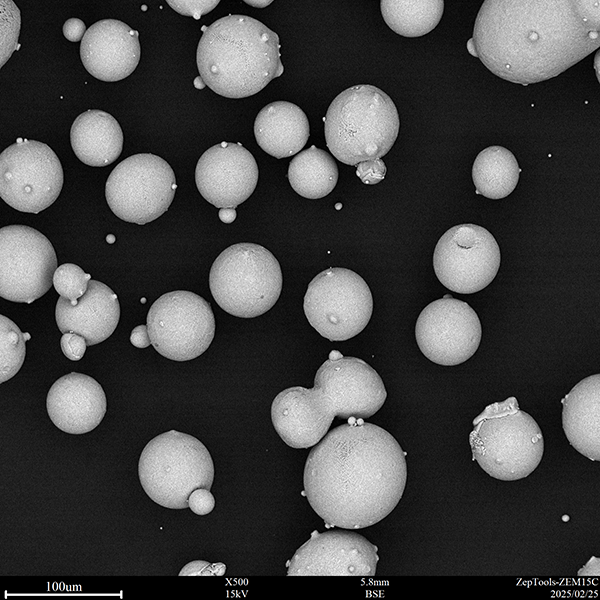

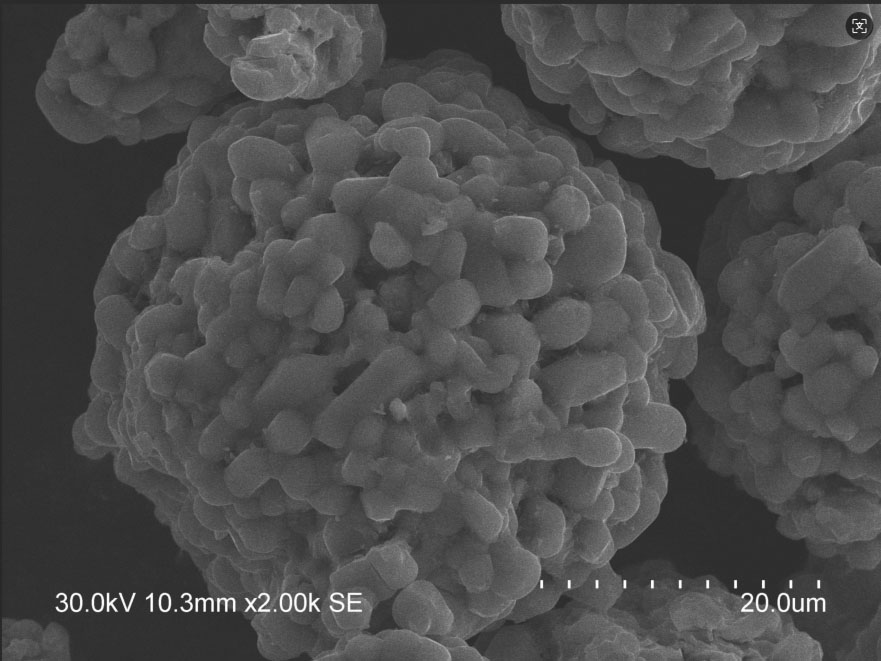

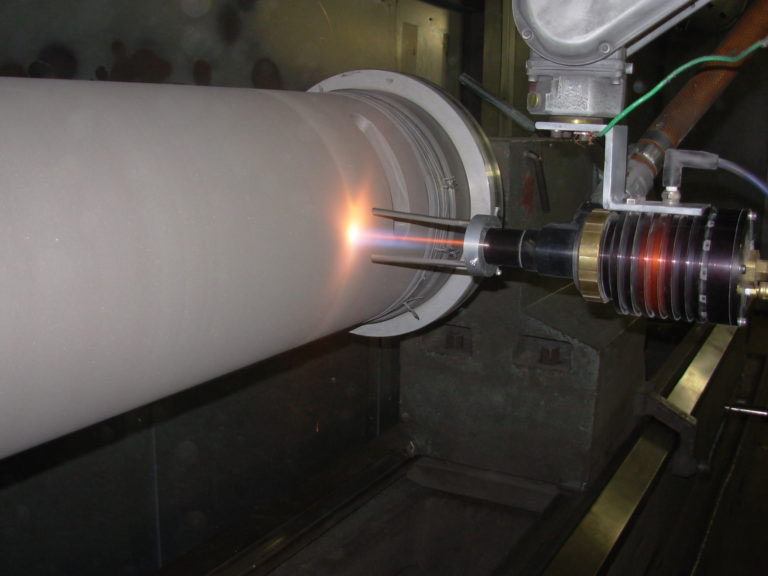

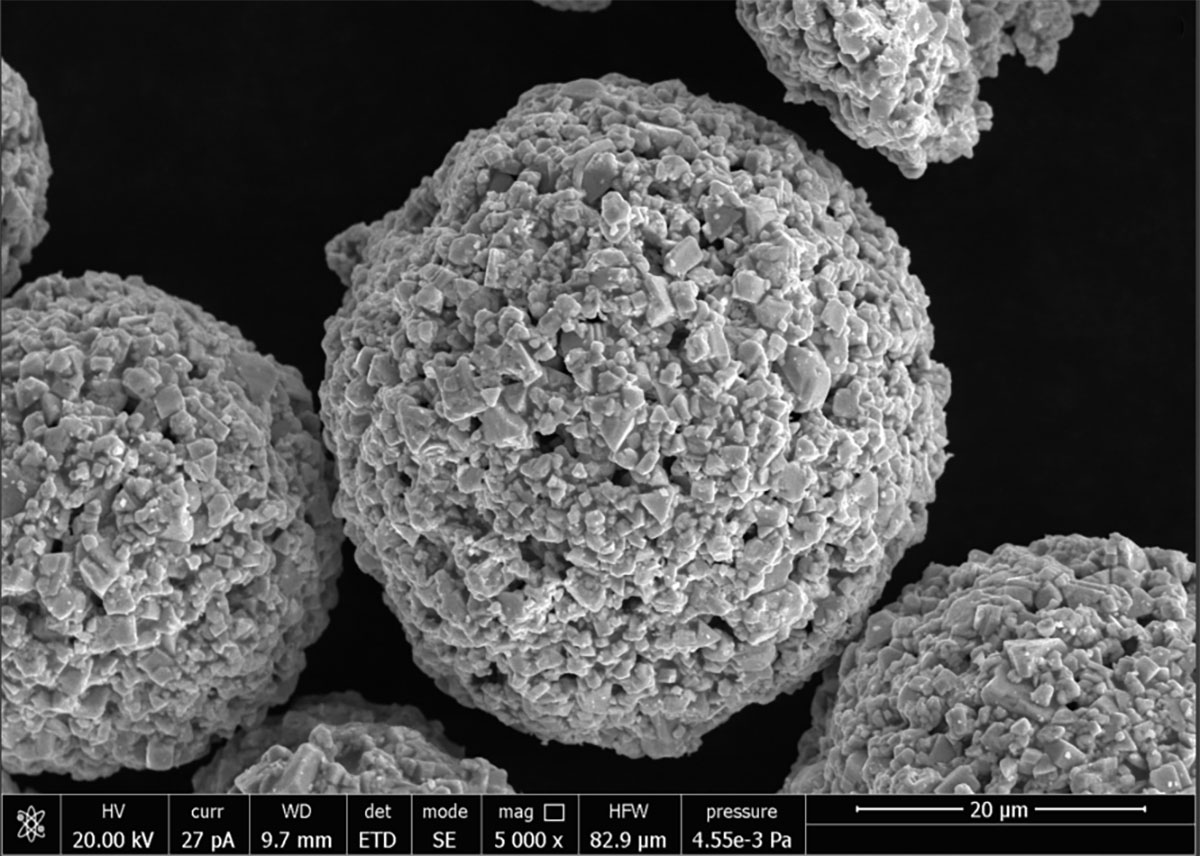

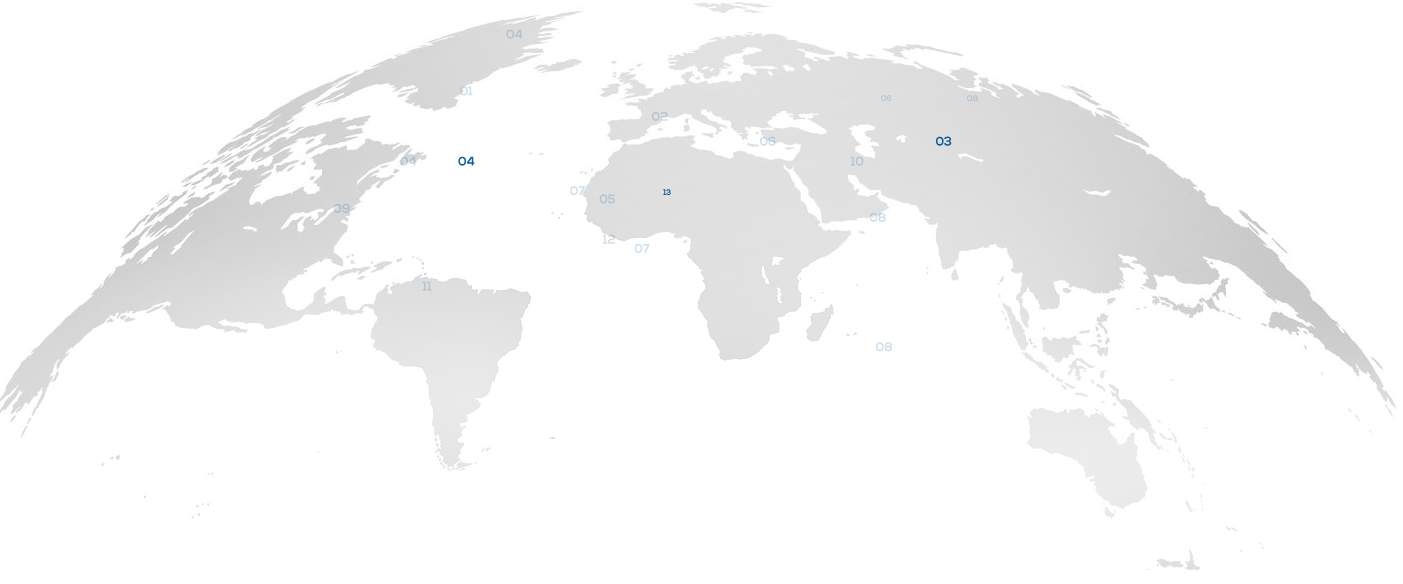

Our company was founded in 1996, is China's professional thermal spraying powder production enterprises, the current annual output value of 200 million yuan, and passed the international ISO9001 certification and high-tech enterprises, in Chengdu Longquan and Xindu two production bases, with 8 powder production lines, the establishment of chemical composition analysis, metallographic analysis and powder performance testing laboratory, built including plasma spraying, supersonic flame spraying, spraying online monitoring and other new spraying process laboratory; The company has advanced agglomeration, water atomization, gas atomization production lines, specializing in the production and sales of nickel-based, cobalt-based, iron-based and carbide powders, products serve more than 1,000 customers in various fields such as steel, petroleum, chemical, automobile, machinery, printing and new energy, additive manufacturing, etc., the company currently has an annual output of more than 5,000 tons of various types of powder.

0102

JOIN US

-

Channel Power

-

Showcase Power

-

Manufacturing Power

-

Product Power

-

Marketing Power

-

Supportive Power

-

Promotional Power

-

Brand Power

Sustainable development of enterprises

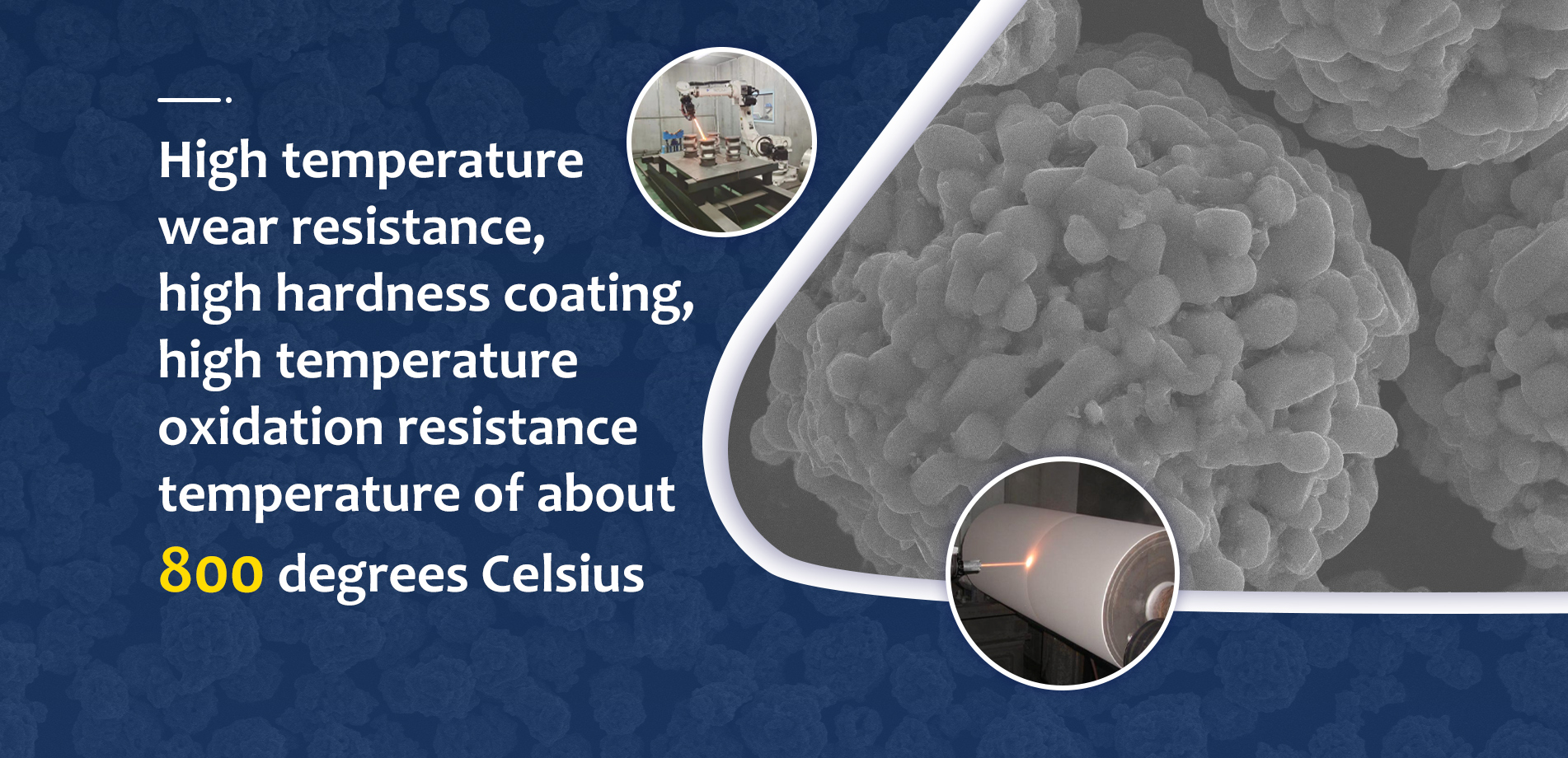

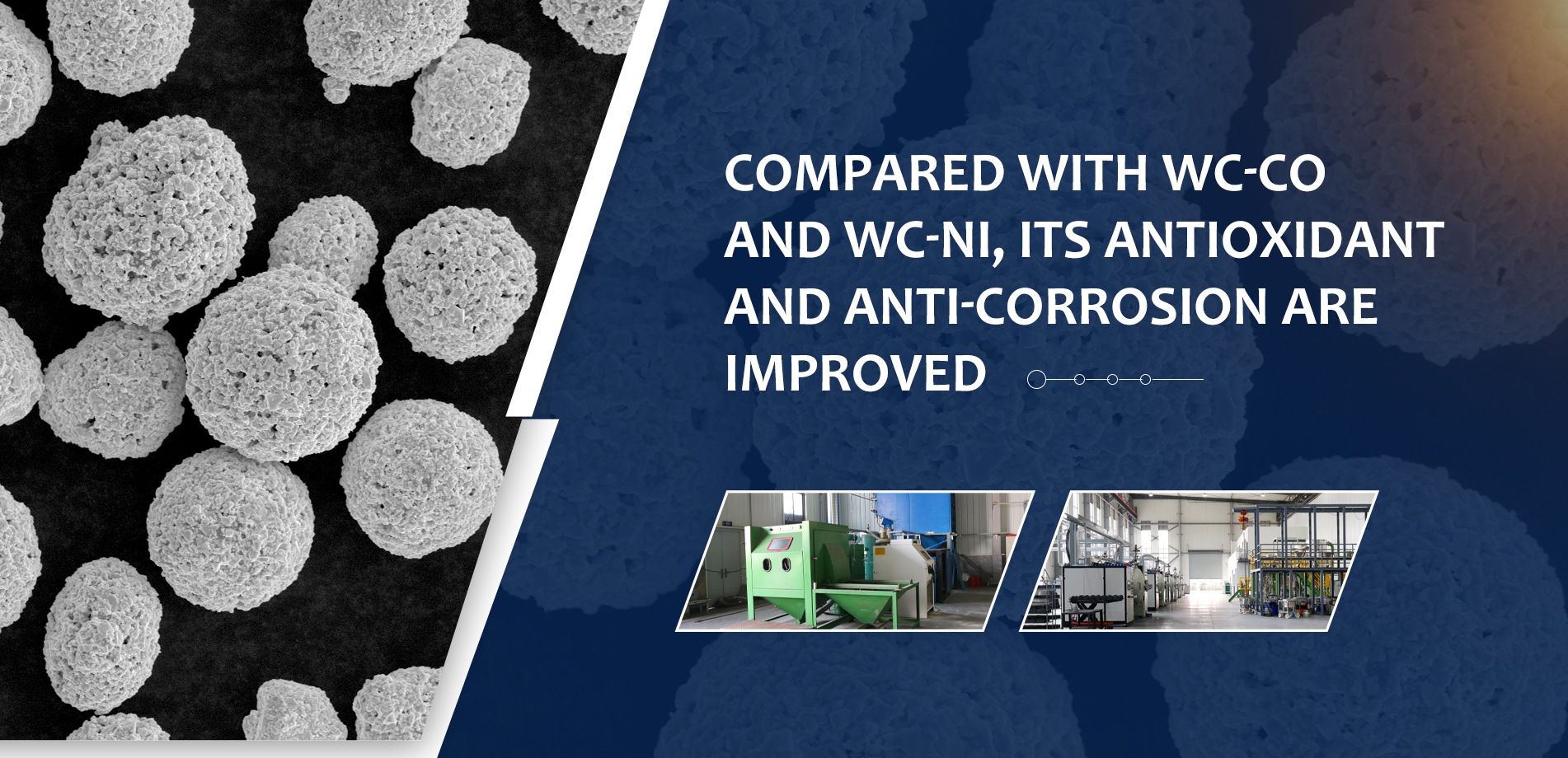

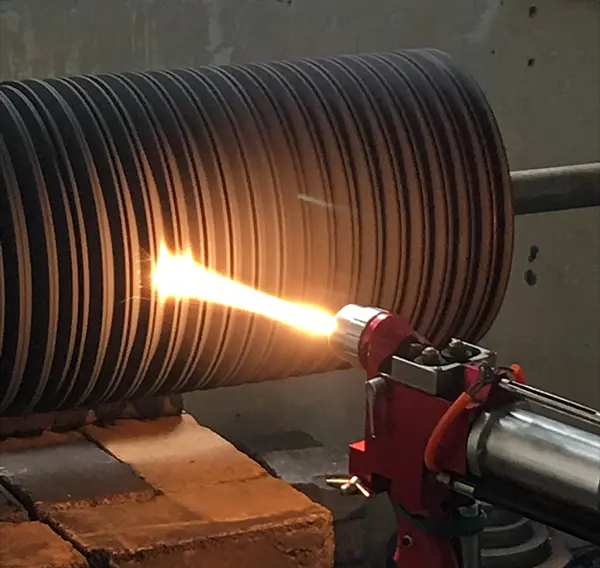

Thermal spraying is a technique in which a coating material is melted or softened at high temperatures and then sprayed onto the surface of a workpiece to form a coating with special properties. This process can significantly improve the wear resistance, corrosion resistance, high temperature resistance, oxidation resistance, etc. of the workpiece, thereby extending its service life.

Explore NowOur Latest News

Keep the information leading, help make accurate decisions, let us meet every new opportunity together!

Explore Now